It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

share:

originally posted by: FlySolo

But clearly, the tools you describe as being the only ones they have, are not able to cut like you suggest.

Further down the same page

These experiments demonstrate that the ancient Egyptians could have, using simple technology and the material available to them during their history, worked rocks with copper, bronze, and iron saws. It would be expected that for soft stones like limestone it was routinely used. In the case of hardrocks like granite, the expense incurred by the loss of copper during the cutting process (less with bronze and iron) would restricted it to royal monuments, for usage where other tools would not suffice (Arnold 1991).

A request for evidence is just that, take it anyway you want.

a reply to: Xtrozero

7000 sound about right. People really couldn't have populate that fast, right after the Flood after all

Also, be careful if you Google whether Egypt had Hebrew slaves, and people say no such records exist(there's record of "some" Hebrew slaves). People said that no evidence exists for a man named Jesus, and we know that's untrue. First, we need to know what exactly the Egyptian records say. Also, watching the Ten Commandments, the Pharaoh told everyone to destroy all records that had the name Moses(though it's unclear if that was just a script or factual), so it's possible that's what happened.

7000 sound about right. People really couldn't have populate that fast, right after the Flood after all

Also, be careful if you Google whether Egypt had Hebrew slaves, and people say no such records exist(there's record of "some" Hebrew slaves). People said that no evidence exists for a man named Jesus, and we know that's untrue. First, we need to know what exactly the Egyptian records say. Also, watching the Ten Commandments, the Pharaoh told everyone to destroy all records that had the name Moses(though it's unclear if that was just a script or factual), so it's possible that's what happened.

originally posted by: FlySolo

a reply to: Xtrozero

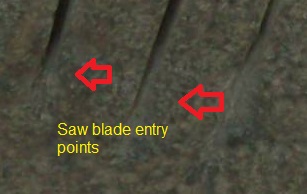

No, you're showing a completed cut in the wood picture. The stone pictures you can see the entry mark from the blade. It's tapered as the blade touches the rock then moves to the right. You can't get this with a hand saw, only a circular saw.

Big assumptions... they are not even close to being uniformed as a saw blade would be...all three are different and do not show what would be crisp cuts that a saw blade would typically have.

originally posted by: FlySolo

a reply to: skalla

Because of the speed they were done. abrasive technology is too slow to end up with three cut marks beside each other for no good reason. That's all

is that a response to:

How do you know they are quick cuts from those small pictures. Genuinely interested.

So are you saying that you know they were quick cuts because of the speed they were done?

And are you suggesting that you somehow know (rather than speculating) that these cuts were quickly done one after the other? If so, how?

And do you have no comment on your statement that you know that these copper tools don't work, in-spite of you relying on some statements in the article (that no such saws have been found) - the same article that contains data on the experiments that show that these tools do work.

These tools were slower than modern tools, but why is that such an obstacle to their use? What would you suggest as an alternative?

a reply to: Xtrozero

Yeah, all three are different because they're all test cuts, like I said in the first place. And it's not an assumption btw. I thought it out before I said it. My reasoning is, if the cut was from the other direction, then it would be deeper than it currently is because of the angle the saw would have to travel to get the length of the cut. Know what I mean? There's only a 1 inch cut at the far right, but it's all the way down the length of the rock. It's not physically possible to make a cut like that from the right to left. With a hand saw to boot. Must be a circular saw and those are the entry points.

Look at this one again closely and think about it.

Yeah, all three are different because they're all test cuts, like I said in the first place. And it's not an assumption btw. I thought it out before I said it. My reasoning is, if the cut was from the other direction, then it would be deeper than it currently is because of the angle the saw would have to travel to get the length of the cut. Know what I mean? There's only a 1 inch cut at the far right, but it's all the way down the length of the rock. It's not physically possible to make a cut like that from the right to left. With a hand saw to boot. Must be a circular saw and those are the entry points.

Look at this one again closely and think about it.

edit on 6-4-2015 by FlySolo because: (no reason given)

a reply to: skalla

First, you need to answer my question. Do you disagree these are test cuts?

So are you saying that you know they were quick cuts because of the speed they were done?

And are you suggesting that you somehow know (rather than speculating) that these cuts were quickly done one after the other? If so, how?

First, you need to answer my question. Do you disagree these are test cuts?

a reply to: FlySolo

I would expect that they are test cuts of some sort, whether for apprenticing, aligning a blade, testing different abrasives/rpms and so forth. That would certainly stand to reason and be the most likely explanation. Others may arrive with good suggestions though.

I would expect that they are test cuts of some sort, whether for apprenticing, aligning a blade, testing different abrasives/rpms and so forth. That would certainly stand to reason and be the most likely explanation. Others may arrive with good suggestions though.

originally posted by: FlySolo

a reply to: Xtrozero

Yeah, all three are different because they're all test cuts, like I said in the first place. And it's not an assumption btw. I thought it out before I said it. My reasoning is, if the cut was from the other direction, then it would be deeper than it currently is because of the angle the saw would have to travel to get the length of the cut. Know what I mean? There's only a 1 inch cut at the far right, but it's all the way down the length of the rock. It's not physically possible to make a cut like that from the right to left. With a hand saw to boot. Must be a circular saw and those are the entry points.

Look at this one again closely and think about it.

Not sure why you say it can not be done with a straight saw. The top one really looks like a saw or abrasive string cut. Sliding an item back and forth with a harder abrasive material between it and the rock will get you this type of cut.

I guess my big point is why do people always look for more complicated means instead of trying to figure out how to do it with simple means. Seems people think this all can't be done with simple tools...we need aliens, lasers mechanical saws etc...but in the end all we have are basic tools as examples...

a reply to: skalla

Well I'm glad we agree on that because it makes this next bit easier. Because they're test cuts, and abrasive cutting is just slightly faster than natural erosion, wouldn't it make more sense to train your apprentices or do your painfully slow arduous testing on the actual project? ?...? That's why theses are quick and that's why abrasive theory doesn't work. Hand saw doesn't work, hundreds of men doesn't work. All of those theories, none of them work. A high powered circular saw does.

Well I'm glad we agree on that because it makes this next bit easier. Because they're test cuts, and abrasive cutting is just slightly faster than natural erosion, wouldn't it make more sense to train your apprentices or do your painfully slow arduous testing on the actual project? ?...? That's why theses are quick and that's why abrasive theory doesn't work. Hand saw doesn't work, hundreds of men doesn't work. All of those theories, none of them work. A high powered circular saw does.

a reply to: Xtrozero

If I have to explain to you why it's physically impossible to get that shape of cut with a back and forth string motion then idk. You just can't. Not looking for complicated means, just saying those theories don't work.

Not sure why you say it can not be done with a straight saw. The top one really looks like a saw or abrasive string cut. Sliding an item back and forth with a harder abrasive material between it and the rock will get you this type of cut.

If I have to explain to you why it's physically impossible to get that shape of cut with a back and forth string motion then idk. You just can't. Not looking for complicated means, just saying those theories don't work.

originally posted by: FlySolo

a reply to: Xtrozero

Not sure why you say it can not be done with a straight saw. The top one really looks like a saw or abrasive string cut. Sliding an item back and forth with a harder abrasive material between it and the rock will get you this type of cut.

If I have to explain to you why it's physically impossible to get that shape of cut with a back and forth string motion then idk. You just can't. Not looking for complicated means, just saying those theories don't work.

Here is another picture of your clean circular saw cuts.. Not so clean from this angle

2x post

edit on 6-4-2015 by Xtrozero because: (no reason given)

a reply to: Xtrozero

I don't necessarily agree that these must be circular saw cuts, but they do have the look of a circular saw plunge cuts.

For those unfamiliar with tools, a circular saw cuts straight lines using a circular blade. Because the blade is circular, you must cut past the end of the piece you want. This leaves marks on the excess material very similar to what we are looking at.

For making circular cuts you use a hole saw. Circular saws do not cut circles. Jig saws and band saws can, but for precise circular cuts a hole saw or drill is required. Hole saw if you want to keep the hole.

Now that that is cleared up, I must agree it is unlikely those three cuts would have been made for any good reason, using hand tools. Not impossible, just very unlikely. You just don't make unnecessary cuts when it takes hours to do so. So if they did use copper tools to do this, those cuts must have been necessary for something. I could think of lots of potential reasons for one here or there, but 3 so close just looks like wasted effort.

I don't necessarily agree that these must be circular saw cuts, but they do have the look of a circular saw plunge cuts.

For those unfamiliar with tools, a circular saw cuts straight lines using a circular blade. Because the blade is circular, you must cut past the end of the piece you want. This leaves marks on the excess material very similar to what we are looking at.

For making circular cuts you use a hole saw. Circular saws do not cut circles. Jig saws and band saws can, but for precise circular cuts a hole saw or drill is required. Hole saw if you want to keep the hole.

Now that that is cleared up, I must agree it is unlikely those three cuts would have been made for any good reason, using hand tools. Not impossible, just very unlikely. You just don't make unnecessary cuts when it takes hours to do so. So if they did use copper tools to do this, those cuts must have been necessary for something. I could think of lots of potential reasons for one here or there, but 3 so close just looks like wasted effort.

a reply to: FlySolo

But there must be suggestions based on the materials that we know that they had, and abrasive cutting is clearly a lot faster than natural erosion, as shown in this experiment

So we have data showing that abrasive cutting does work, at a far greater rate than natural erosion. Suggesting otherwise is not supported by evidence,

So given what we do know of their tech and resources, what would you say are the possible materials such a circular saw would be made of?

But there must be suggestions based on the materials that we know that they had, and abrasive cutting is clearly a lot faster than natural erosion, as shown in this experiment

The rate of rock removal is similar for both the wet and dry sand tests at about 12 cm3/hour. Stocks (2001), after comparing the ratios of volume, weight, and depth of removal between the copper saw blade and the granite block (Fig. 8), concludes that the dry test with its flat-edged blade is distinctly better than that of the wet sand test with its notched blade. This is the result of the rate of degradation of the copper saw blade being greater in the wet tests, resulting in a more costly enterprise. As well, the tailing from dry cutting can be collected and used for other purposes. Because of the inexperience of the work teams in these modern experiments, it was suggested by Stocks (2001) that the rate of cutting could be increased by a factor of 2 with increased experience.

So we have data showing that abrasive cutting does work, at a far greater rate than natural erosion. Suggesting otherwise is not supported by evidence,

So given what we do know of their tech and resources, what would you say are the possible materials such a circular saw would be made of?

originally posted by: skalla

a reply to: FlySolo

So what is the circular saw made of and how is it powered?

how about wood, with a rather thick copper edge, and water power? Uses sand t do actual cutting...

There has been stuff on History channel about it. There are some who think they have found the saws, or rather what's left of them.

a reply to: Xtrozero

You're being obtuse. If I made a cut in the rock like that with my finger, you would say "it's not straight". Besides, look at the entry mark on the right and not on the left. You can even see the depth as it progresses and just stops. lol. Maybe they used dental floss to scratch that out back then.

You're being obtuse. If I made a cut in the rock like that with my finger, you would say "it's not straight". Besides, look at the entry mark on the right and not on the left. You can even see the depth as it progresses and just stops. lol. Maybe they used dental floss to scratch that out back then.

a reply to: tanka418

Yeps, copper hand saws/wire or discs; using abrasive, powered by by hand/pole-lathe type arrangements, maybe water power. All excellent suggestions and in line with their other tech - i've been advocating the same thing for far too many pages

Yeps, copper hand saws/wire or discs; using abrasive, powered by by hand/pole-lathe type arrangements, maybe water power. All excellent suggestions and in line with their other tech - i've been advocating the same thing for far too many pages

new topics

-

A Warning to America: 25 Ways the US is Being Destroyed

New World Order: 3 hours ago -

President BIDEN's FBI Raided Donald Trump's Florida Home for OBAMA-NORTH KOREA Documents.

Political Conspiracies: 9 hours ago -

Maestro Benedetto

Literature: 10 hours ago -

Is AI Better Than the Hollywood Elite?

Movies: 10 hours ago

top topics

-

President BIDEN's FBI Raided Donald Trump's Florida Home for OBAMA-NORTH KOREA Documents.

Political Conspiracies: 9 hours ago, 28 flags -

Gaza Terrorists Attack US Humanitarian Pier During Construction

Middle East Issues: 15 hours ago, 8 flags -

Massachusetts Drag Queen Leads Young Kids in Free Palestine Chant

Social Issues and Civil Unrest: 17 hours ago, 7 flags -

Las Vegas UFO Spotting Teen Traumatized by Demon Creature in Backyard

Aliens and UFOs: 14 hours ago, 6 flags -

A Warning to America: 25 Ways the US is Being Destroyed

New World Order: 3 hours ago, 6 flags -

Meadows, Giuliani Among 11 Indicted in Arizona in Latest 2020 Election Subversion Case

Mainstream News: 17 hours ago, 5 flags -

2024 Pigeon Forge Rod Run - On the Strip (Video made for you)

Automotive Discussion: 15 hours ago, 4 flags -

Is AI Better Than the Hollywood Elite?

Movies: 10 hours ago, 3 flags -

The functionality of boldening and italics is clunky and no post char limit warning?

ATS Freshman's Forum: 16 hours ago, 1 flags -

Maestro Benedetto

Literature: 10 hours ago, 1 flags

active topics

-

-@TH3WH17ERABB17- -Q- ---TIME TO SHOW THE WORLD--- -Part- --44--

Dissecting Disinformation • 691 • : Imbackbaby -

Alternate Electors vs Fake Electors - What is the Difference.

2024 Elections • 116 • : Threadbarer -

Gaza Terrorists Attack US Humanitarian Pier During Construction

Middle East Issues • 34 • : AllisVibration -

Victoria government has cancelled the commmonwealth games, no money.

Regional Politics • 3 • : nazaretalazareta -

A Warning to America: 25 Ways the US is Being Destroyed

New World Order • 2 • : Disgusted123 -

President BIDEN's FBI Raided Donald Trump's Florida Home for OBAMA-NORTH KOREA Documents.

Political Conspiracies • 19 • : ADVISOR -

When an Angel gets his or her wings

Religion, Faith, And Theology • 22 • : AcrobaticDreams1 -

King Charles 111 Diagnosed with Cancer

Mainstream News • 321 • : FlyersFan -

Is there a hole at the North Pole?

ATS Skunk Works • 41 • : burritocat -

Massachusetts Drag Queen Leads Young Kids in Free Palestine Chant

Social Issues and Civil Unrest • 16 • : FlyersFan