It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

share:

originally posted by: FlySolo

Why cut quickly? Just look at it. Do you disagree these are test cuts? And time on your side doesn't mean jobs are done less efficiently. In other words, just because there wasn't facebook or TV back then doesn't equate to more time spent on a job because there's nothing else to do. In fact, it would be prudent to go as fast as possible. More man power doesn't make a task necessarily go faster either. Specifically that particular picture. Horse power would be the better term because that test cut is a one-man job.

I think I was looking at what you were suggesting as quick to be something other than human power. I agree, craftsmen had little in their life to take them away from their craft.

originally posted by: ISawItFirst

So why don't we hear more about these channels. Are all our copper sand guys going to say they drilled through all the blocks in their final place? Or did they drill them one at a time from elaborate mathematical plans and stack the blocks accordingly?

I picture some giant wooden jig holding a 100 meter sagging wooden drilling rod hanging off the side of the pyramid in a gravity defying dance with.... well, it doesn't matter what I think. Notwithstanding, it is clear to me that whomever built them, wanted us to know that the procession of the equinoxes is very significant.

Building yard

This is the center of the whole construction site. All the work, all assignments are planned and coordinated here. The route of each stone has to be scheduled and its shape and size and its intended place on the pyramid has to be decided in advance.

At the building yard the stones were placed in the right order to see if they fit together. This was written down on the blocks and then they were transported, still tied to the same sledge, in the correct order to the building site and up the flank of the pyramid.

Each stone was examined by a master builder and most passed without any changes necessary. But sometimes a stone with the wrong size or shape was delivered or a flawed stone had to be replaced. At the workshop those stones were cut to the size and shape required.

For a standard size stone (stone blocks from the Giza quarries) a stonemason needed about 4 to 5 hours with good tools. For a casing stone (from the Tura quarries) about 8-10 hours, for a corner stone probably more like 10-12 hours. To process the 500 stones daily about 300 stonemasons were needed and as much helpers.

An important part was played by the smiths that had to manufacture and maintain the iron tools. We calculate 100 smiths and twice as much additional helpers.

Building Yard

So yes the stones were all pre-planned and marked as to where they needed to go before they were moved to the pyramid.

a reply to: skalla

ah read enough

You're one of those theorists whom believe more manual labor was involved using rather mundane methods. Sorry, can't get behind that. Clearly, it's a circular saw. And a small one about 8" in diameter. As per the second picture I found.

ah read enough

If the principle works (and it clearly does), then there would be any number of ways to do it - all one needs to do is make sure that the string travels in a straight line and that's not too difficult. More workers can just mean more work per hour, as such.

You're one of those theorists whom believe more manual labor was involved using rather mundane methods. Sorry, can't get behind that. Clearly, it's a circular saw. And a small one about 8" in diameter. As per the second picture I found.

a reply to: skalla

what kind of RPM's are you going to get out of a pole-lathe? A copper wheel how thick? What adhesive will you use to adhere the abrasive to copper? Not shooting it down but copper has a melting point of 1,000 degrees Celsius. How hot do you think sawing through rock is going to be? What about coolant? Hoses?? buckets of water? Buckets and buckets, like thousands and thousands of buckets of water. Again, I would like to reiterate that the pictures I noticed are quick cuts and they aren't going to waste any time doing that.

what kind of RPM's are you going to get out of a pole-lathe? A copper wheel how thick? What adhesive will you use to adhere the abrasive to copper? Not shooting it down but copper has a melting point of 1,000 degrees Celsius. How hot do you think sawing through rock is going to be? What about coolant? Hoses?? buckets of water? Buckets and buckets, like thousands and thousands of buckets of water. Again, I would like to reiterate that the pictures I noticed are quick cuts and they aren't going to waste any time doing that.

edit on 6-4-2015 by FlySolo because: (no reason

given)

originally posted by: pheonix358

Those saw cuts look like an angle grinder was used and could have been cut any time since angle grinders were invented.

It looks as though much of the area has had much of the stone work carried away probably for local building projects and this has happened many times before in many areas.

On the other hand, it is very smooth cutting on the surface and does the beg the question.

But honestly, for every time that 'they' have said this or that could not have been done by ancient man, someone comes up and proves them wrong. From Easter Island to the guy in the US who moves around 25 ton slabs by himself.

They did have two handed saws in those days and just because we have lost the knowledge of how it was done, does not mean that they did not do it all.

Having said all of that, it is amazing how flat they managed to get those rocks.

Power tools? I don't believe so. You just have to look at the huge Cathedrals and Castles in Europe and elsewhere to know that man could build awesome things without power tools.

P

I've seen even easier explanations. There's a basic technique of putting sand on stone, then rubbing the straight tool back & forth on the sand. The sand grinds the rock away & looks like "cuts". You just keep adding more sand as you go.

a reply to: enlightenedservant

You are right.. shaft holes can be drilled into flint mace heads (for example) using a river cane as a hand drill and sand/flint dust as the abrasive.

Here is a vid showing the process, but with the much softer Slate.

Harder stone just takes more time and more river cane.

You are right.. shaft holes can be drilled into flint mace heads (for example) using a river cane as a hand drill and sand/flint dust as the abrasive.

Here is a vid showing the process, but with the much softer Slate.

Harder stone just takes more time and more river cane.

originally posted by: FlySolo

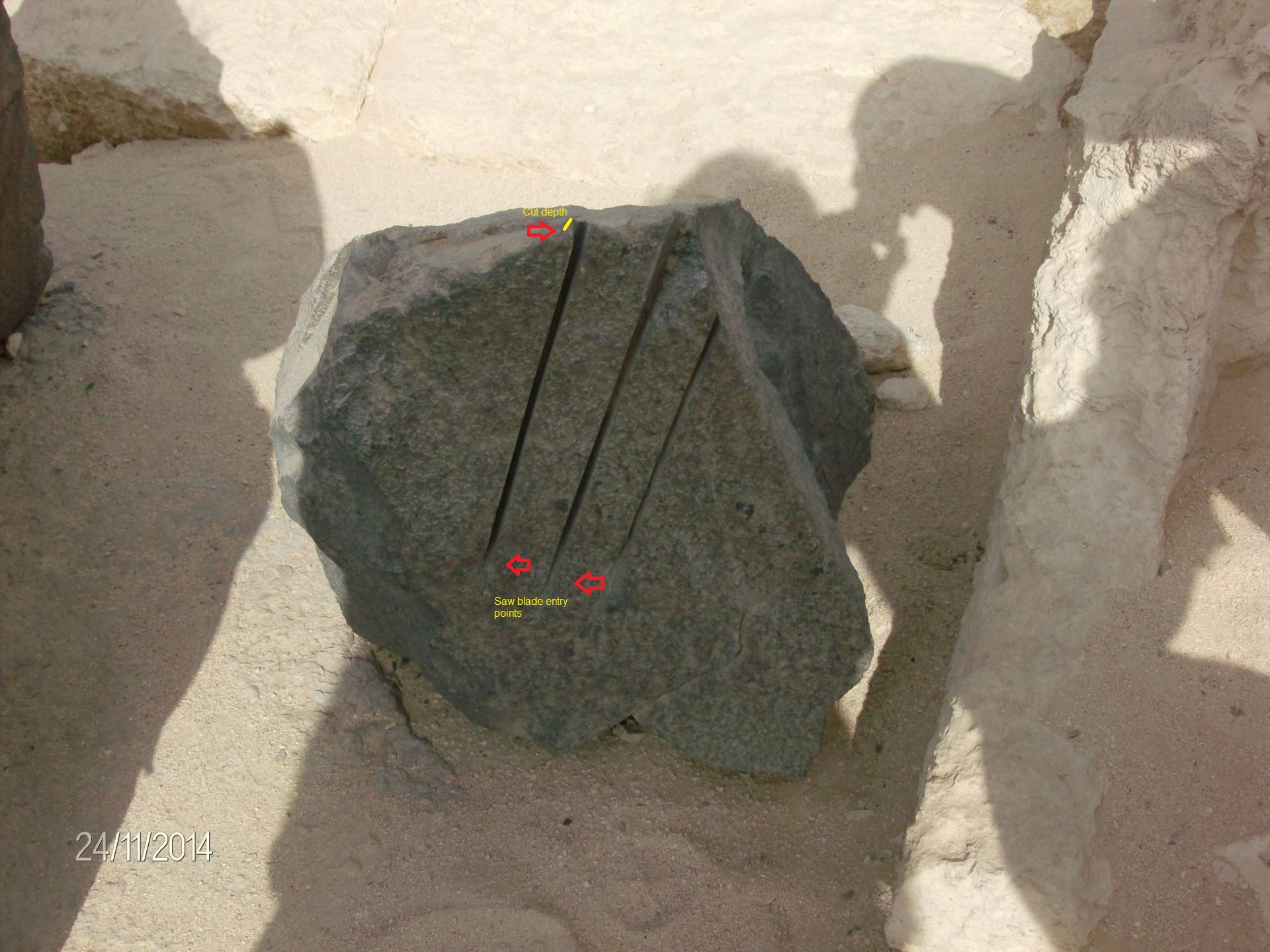

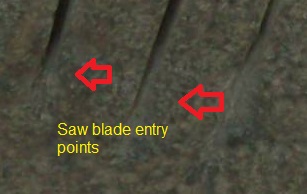

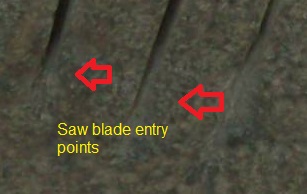

looking at that picture again zoomed in on my computer, those cut marks are very telling. It would appear a 1 inch cut was made with a circular saw judging by the entry marks.

eta: I decided to back up my theory with a google search of " saw cut marks stone" to see what the masonry results are like and I found this:

Notice how crisp and parallel the edges are. The quality of this work indicates that the blade was held completely steady. Apparently, cutting basalt was not so slow and arduous that extra cuts like these would have been avoided as being an unnecessary waste of time.

My thoughts exactly.

Why a "circular saw"? It seems you see a straight cut and then say CIRCULAR SAW!!

Was this piece of wood cut with a handsaw or circular saw?

The only way to really tell is to look at the cut, and a saw would have straight cut lines and a circular saw has circular cut lines, so what would you say these cut lines are from the OPS post? Straight or Circular?

edit on 6-4-2015 by Xtrozero because: (no reason given)

a reply to: skalla

But clearly, the tools you describe as being the only ones they have, are not able to cut like you suggest. And the evidence I have is just common sense. The pictures I've shown, are of three cuts. Each, a little deeper than the other which tells me their setting the blade depth and doing a test cut. Something like that would be done quickly. Otherwise, finished cuts would be much more crude, all uneven.

It's not a no brainer when those are the tools that you have.

But clearly, the tools you describe as being the only ones they have, are not able to cut like you suggest. And the evidence I have is just common sense. The pictures I've shown, are of three cuts. Each, a little deeper than the other which tells me their setting the blade depth and doing a test cut. Something like that would be done quickly. Otherwise, finished cuts would be much more crude, all uneven.

a reply to: Xtrozero

No, you're showing a completed cut in the wood picture. The stone pictures you can see the entry mark from the blade. It's tapered as the blade touches the rock then moves to the right. You can't get this with a hand saw, only a circular saw.

And this picture...

Is whole different animal. And not what I was talking about as being cut with a circular saw so I don't know why you're trying to refute me with it. I will say, it's even more technologically advanced and not a good argument for any mundane explanation.

No, you're showing a completed cut in the wood picture. The stone pictures you can see the entry mark from the blade. It's tapered as the blade touches the rock then moves to the right. You can't get this with a hand saw, only a circular saw.

And this picture...

Is whole different animal. And not what I was talking about as being cut with a circular saw so I don't know why you're trying to refute me with it. I will say, it's even more technologically advanced and not a good argument for any mundane explanation.

edit on 6-4-2015 by FlySolo because:

(no reason given)

a reply to: skalla

HAHAHAHA

You're easy.

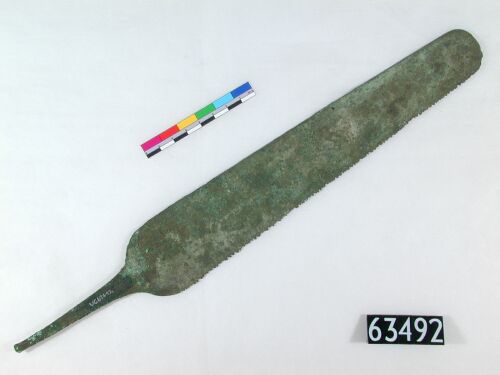

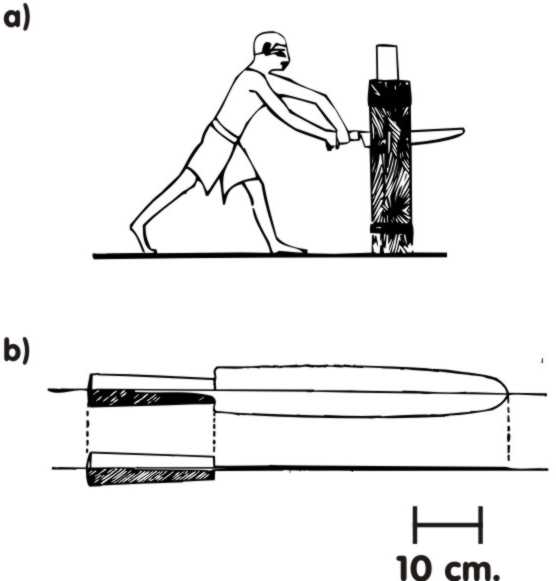

I'm already two steps ahead of you. There is no depiction of Egyptians using saws to slab rock and these copper saws are used for carpentry.

ETA: FYI to the members reading this. He snipped that picture and left the write up below it, which I provided, along with the link he got it from which is here.

www.oocities.org...

HAHAHAHA

You're easy.

In ancient Egyptian art no representations have been found of the sawing of stone by means of a copper blade and an abrasive (Lucas & Harris 1962, Stocks 1999), nor has any lapidary slabing saws been found in the archaeological record (Arnold 1991). However, the ancient Egyptians had copper saw blades, which they employed in carpentry, and are frequently represented in Egyptian art (Fig. 1a). Examples of carpentry saws from very early in the ancient Egyptian civilization (1st-3rd Dynasty) have been found (Emery 1972, Arnold 1991). These early copper saws are of a variety of lengths up to 40 cm (image). Usually, only one edge of the blade is serrated and meant to be pulled and not pushed during cutting (i.e. rip-saw), and the blade is socketed into a straight wooden handle (Fig. 1b). An example of a fragment of an ancient Egyptian copper saw can be found at the Petrie Museum (UC30854).

I'm already two steps ahead of you. There is no depiction of Egyptians using saws to slab rock and these copper saws are used for carpentry.

ETA: FYI to the members reading this. He snipped that picture and left the write up below it, which I provided, along with the link he got it from which is here.

www.oocities.org...

edit on 6-4-2015 by FlySolo because: (no reason

given)

a reply to: FlySolo

That's good, i'm asking a genuine question to understand more - could you provide the link for that?

Yep, i did an image search and quickly copied the pic, totally not ashamed to admit an error

That's good, i'm asking a genuine question to understand more - could you provide the link for that?

Yep, i did an image search and quickly copied the pic, totally not ashamed to admit an error

edit on 6-4-2015 by skalla because: (no reason

given)

new topics

-

Pentagon acknowledges secret UFO project, the Kona Blue program | Vargas Reports

Aliens and UFOs: 57 minutes ago -

Boston Dynamics say Farewell to Atlas

Science & Technology: 1 hours ago -

I hate dreaming

Rant: 1 hours ago -

Is the origin for the Eye of Horus the pineal gland?

Philosophy and Metaphysics: 3 hours ago -

Man sets himself on fire outside Donald Trump trial

Mainstream News: 3 hours ago -

Biden says little kids flip him the bird all the time.

2024 Elections: 3 hours ago -

The Democrats Take Control the House - Look what happened while you were sleeping

US Political Madness: 4 hours ago -

Sheetz facing racial discrimination lawsuit for considering criminal history in hiring

Social Issues and Civil Unrest: 4 hours ago -

In an Historic First, In N Out Burger Permanently Closes a Location

Mainstream News: 6 hours ago -

MH370 Again....

Disaster Conspiracies: 6 hours ago

top topics

-

In an Historic First, In N Out Burger Permanently Closes a Location

Mainstream News: 6 hours ago, 14 flags -

The Democrats Take Control the House - Look what happened while you were sleeping

US Political Madness: 4 hours ago, 10 flags -

Thousands Of Young Ukrainian Men Trying To Flee The Country To Avoid Conscription And The War

Other Current Events: 17 hours ago, 8 flags -

A man of the people

Medical Issues & Conspiracies: 11 hours ago, 8 flags -

Man sets himself on fire outside Donald Trump trial

Mainstream News: 3 hours ago, 7 flags -

Biden says little kids flip him the bird all the time.

2024 Elections: 3 hours ago, 6 flags -

4 plans of US elites to defeat Russia

New World Order: 13 hours ago, 4 flags -

Is the origin for the Eye of Horus the pineal gland?

Philosophy and Metaphysics: 3 hours ago, 4 flags -

Sheetz facing racial discrimination lawsuit for considering criminal history in hiring

Social Issues and Civil Unrest: 4 hours ago, 3 flags -

Are you ready for the return of Jesus Christ? Have you been cleansed by His blood?

Religion, Faith, And Theology: 9 hours ago, 3 flags

active topics

-

Pentagon acknowledges secret UFO project, the Kona Blue program | Vargas Reports

Aliens and UFOs • 3 • : onestonemonkey -

12 jurors selected in Trump criminal trial

US Political Madness • 107 • : Xtrozero -

Man sets himself on fire outside Donald Trump trial

Mainstream News • 30 • : HatesFreshAir -

The Democrats Take Control the House - Look what happened while you were sleeping

US Political Madness • 36 • : DBCowboy -

The defamation of Mary Magdalene

Religion, Faith, And Theology • 14 • : DISRAELI2 -

Mood Music Part VI

Music • 3063 • : lilzazz -

Russian intelligence officer: explosions at defense factories in the USA and Wales may be sabotage

Weaponry • 176 • : BernnieJGato -

-@TH3WH17ERABB17- -Q- ---TIME TO SHOW THE WORLD--- -Part- --44--

Dissecting Disinformation • 543 • : SideEyeEverything1 -

Elites disapearing

Political Conspiracies • 33 • : 0bserver1 -

Fossils in Greece Suggest Human Ancestors Evolved in Europe, Not Africa

Origins and Creationism • 78 • : strongfp