It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

share:

Remember the big argument over this photo being a thermate cut or a torch cut:

Well, I think I have it solved for you... here is what the cut pieces look like when cut by hand:

Look in th lower left corner... no metal globs on any of them:

No slag here either:

And this "chunk" looks to have been cut in MANY places... still... no black globby slag like in the first photo:

So... where did all the slag on that first column come from?

[edit on 1-5-2007 by Pootie]

Well, I think I have it solved for you... here is what the cut pieces look like when cut by hand:

Look in th lower left corner... no metal globs on any of them:

No slag here either:

And this "chunk" looks to have been cut in MANY places... still... no black globby slag like in the first photo:

So... where did all the slag on that first column come from?

[edit on 1-5-2007 by Pootie]

From what I've read when you cut a column with a torch the melted slag is sprayed away by the force of the oxygen from the torch.

Notice that at the corners there is no slag, as if it was cut through leaving just the corners attached. Cut through, just enough so that the weight of the building would shear the columns making it collapse from the top down?

And yes there are other columns cut straight across with no slag. Why the difference?

[edit on 1/5/2007 by ANOK]

Notice that at the corners there is no slag, as if it was cut through leaving just the corners attached. Cut through, just enough so that the weight of the building would shear the columns making it collapse from the top down?

And yes there are other columns cut straight across with no slag. Why the difference?

[edit on 1/5/2007 by ANOK]

Originally posted by ANOK

Notice also there are other columns cut straight across with no slag.

Some are at an angle without slag... Some are straight without slag...

ONE is at an angle WITH slag... I wish there were more photos like the fireman one...

Now this is a good argument. When I first saw those cuts I thought it was cut by the resue crew and firemen. Now that first photo looks like a

thermate cut. But the others are clean.

[edit on 5/1/2007 by Leyla]

[edit on 5/1/2007 by Leyla]

What we really need to do is get a couple columns and set thermate charges off on them and see what it looks like and see if it's possible to have

them cut horizontally. I say a couple because we need to do different ones like nanothermate in solgel etc.

Well I could do that this summer, but where do you find high-quality construction-grade steel? Seriously... we need people in construction... I know

someone, I'll come back with the answer as soon as I can... but do you have any ideas where we could find such things?

[edit on 3-5-2007 by Vitchilo]

[edit on 3-5-2007 by Vitchilo]

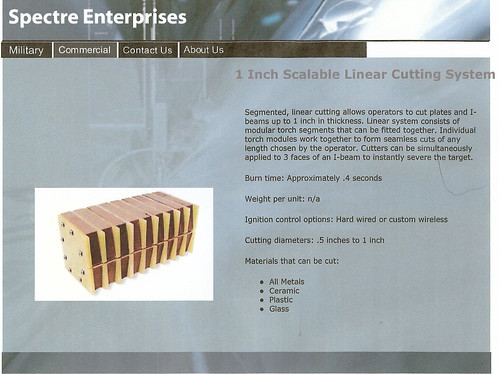

You might be able to try out this:

From patent documentation:

From a researcher with Scholars for 9/11 Truth and Justice:

It would be interesting to see (1) what the cut looks like, and (2) what the device itself looks like after its been used. Obviously something like this hanging around, especially multiples of them, would be suspicious. Thus these would have limited use.

Technologies using sol-gels would be more realistic, because they wouldn't leave behind so much evidence, but try finding patents for devices using that kind of technology. Sol-gel thermites exist, but if actual devices for cutting steel beams exist, I have a feeling it wouldn't be in public domain because you normally wouldn't have to resort to that kind of thing for a commerical, out-in-the-open demolition.

From patent documentation:

From a researcher with Scholars for 9/11 Truth and Justice:

Here are some side notes from my conversation with the inventor's son a short time ago:

1. A modified apparatus is also available (ganged application/linear cutting) which operates using a "shotgun" effect---That is--The three devices (for an "I-beam") or four devices (for a box column) are simultaneously detonated rather than in a short sequential manner.

2. The linear cutter is all formed from a type of plastic. Visually, the yellow end pieces appear to be of the more standard type, while the brownish middle is of a different type.

3. Note that there is an internal ring which surrounds the thermite charge.

4. Note that the inventor's son indicated that he would have to speak to his father (the inventor) regarding the thermate, as he had not heard of that substance before.

5. The positioning of the apparatus is a "critical" matter, as variations in its effect on the target material can result if the device is moved from its initial position upon the start of the reaction.

6. The company does have video (presumably not in mpeg format) of the test cut on the I-beam, and other materials

7. The company has put together demonstrations of their various products.

8. The representative stressed that when mock ups are made for "special forces" (Army) and other military applications, the entity will purchase a few and then try to have mass production commenced at a national lab.

9. Note: The inventor did have a relationship with Sandia Labs, N.M. as shown in this thread.

It would be interesting to see (1) what the cut looks like, and (2) what the device itself looks like after its been used. Obviously something like this hanging around, especially multiples of them, would be suspicious. Thus these would have limited use.

Technologies using sol-gels would be more realistic, because they wouldn't leave behind so much evidence, but try finding patents for devices using that kind of technology. Sol-gel thermites exist, but if actual devices for cutting steel beams exist, I have a feeling it wouldn't be in public domain because you normally wouldn't have to resort to that kind of thing for a commerical, out-in-the-open demolition.

Originally posted by Pootie

Remember the big argument over this photo being a thermate cut or a torch cut:

Well, I think I have it solved for you... here is what the cut pieces look like when cut by hand:

Look in th lower left corner... no metal globs on any of them:

Let me lend you a hand here. I cut steel for a living. Not one single photo showing cut steel from 9/11 in my opinion can be attributed to being burned using thermite. Every single picture I have seen (as best I can tell) shows a normal pattern of a torch moving in a line across a surface producing the usual ribbed cut pattern. A thermite burn would not produce a uniform cut pattern like any known torch. it would just melt away a section, but a torch cut will always produce marks as it travels across the work surface.

There is a reason there are no "metal globs" in the second picture. Frankly it is because it is loose material that is basically scrap metal and has no other value, not even forensic as the composition of the orginial steel is lost when it is remelted.

No slag here either:

Again, slag is not going to tell you anything we don't already know.

And this "chunk" looks to have been cut in MANY places... still... no black globby slag like in the first photo:

If you view the above picture in a photo editor - especially the H beam on the left - you will notice manual cuts made at angles that avoids the center web. A thermite burn will not discriminate on which direction to burn, but a guy with a torch will.

So... where did all the slag on that first column come from?

That slag came from the cut that cooled and accumulated much like an icycle does in the winter. It was just never removed afterwards, because there is no reason to if you are just selling the finished product as scrap.

Thanks for the info. In the paper of Steven Jones, he said that he found sol-gel thermite signature in the sample he could obtain. So it must be

somewhere in the public domain that kind of thing, or it's military grade... but it exist.

Originally posted by Vitchilo

Well I could do that this summer, but where do you find high-quality construction-grade steel? Seriously... we need people in construction... I know someone, I'll come back with the answer as soon as I can... but do you have any ideas where we could find such things?

[edit on 3-5-2007 by Vitchilo]

There is little practical difference in the melting points of tool steels and general purpose steels. They do have different mechanical properties, but that does not seem to be your goal here.

Besides, the majority of the WTC steel was made from what is now known as A36 which is available at every corner drug store.

The steel has not changed much, but the standards have. Where do you live and I can drop as much A36 as you want on your doorstep if you pay the shipping.

[edit on 3-5-2007 by ben91069]

The steel has not changed much, but the standards have. Where do you live and I can drop as much A36 as you want on your doorstep if you pay the shipping.

Well then why don't you do it? Cook some thermite or buy and do the experiment... Anyway I'll try to find some A36 grade steel where I live.

Originally posted by Vitchilo

The steel has not changed much, but the standards have. Where do you live and I can drop as much A36 as you want on your doorstep if you pay the shipping.

Well then why don't you do it? Cook some thermite or buy and do the experiment... Anyway I'll try to find some A36 grade steel where I live.

Look, I am not proposing that thermite was not involved but just that I have seen no close-up photos of cuts that can prove a distinct cut that is different from a normal cutting torch. Can you?

I am not in any way trying to discredit your theory. If you show me a picture with enough detail from 9/11 steel of cuts that have a definite cut pattern from a torch and one from thermite, I will personally arrange to have A36 (or the most similar standard) steel samples sent to you or any lab in the quantities needed to prove the visual cut theory at my cost if you can validate that there is a difference between the photo evidence between a thermite cut and a cut with a torch.

Hell, if you are within 50 miles of me I will give you steel to play with - how is that?

From what I know thermite would not cut in a straight line like that,doesn't it act like acid in a way?I've used cutting torches in the past,Ive

never cut anything that thick but that pic look's like a torch cut to me.

Originally posted by ben91069

That slag came from the cut that cooled and accumulated much like an icycle does in the winter. It was just never removed afterwards, because there is no reason to if you are just selling the finished product as scrap.

So, the entire point of your post is that in ALL except the first picture the SLAG WAS "REMOVED" for resale"? That makes no sense and I think you are missing my point.

Originally posted by Pootie

Originally posted by ben91069

That slag came from the cut that cooled and accumulated much like an ice-cycle does in the winter. It was just never removed afterwards, because there is no reason to if you are just selling the finished product as scrap.

So, the entire point of your post is that in ALL except the first picture the SLAG WAS "REMOVED" for resale"? That makes no sense and I think you are missing my point.

I believe you have missed my point. The slag is absolutely worthless for anything other than scrap metal and paperweights. The absence of slag does not mean thermite was used. Every single picture shows cut steel processed with a torch, and the argument is that the lack of slag shows "somehow" that a torch wasn't used.

Couldn't it just mean the slag was removed? Wouldn't that simplify the whole debate without having to invent a way for thermite to not produce slag, which it always will.

Now back to the topic, show me pictures of a torch cut and a thermite cut so we can see the difference.

Originally posted by ben91069

Every single picture shows cut steel processed with a torch, and the argument is that the lack of slag shows "somehow" that a torch wasn't used.

No... the first picture shows a column cut at a 45 by "something" that left a ton of slag behind and a very messy cut...

The rest of the pictures show TORCH CUTS... clean, straight (as in not jagged), no slag.

Your idea that they "cleaned" the slag for resale is a bit silly. They are going to melt it down anyway, why would the buyer care if there was a little slag on it? Would it be cost effective to "wipe it off" of every cut as you imply?

Originally posted by Pootie

Your idea that they "cleaned" the slag for resale is a bit silly. They are going to melt it down anyway, why would the buyer care if there was a little slag on it? Would it be cost effective to "wipe it off" of every cut as you imply?

They did not clean the slag for resale, but I assure you it was recycled. They cleaned it because the slag is not necessary to study the steel as it is scrap.

Now, do you have a picture of a cut made with thermite or are you still going to just say stuff without backing it up. Prove that the top picture was made with thermite. Thermite only cuts beams at 45 degree angles? Thermite produces no slag?

Let me reiterate that slag can be sold as scrap but it is not the primary reason these beams were cleaned, just so you do understand what I am saying and are not tempted to put words into my mouth again that I am saying that the slag was removed just for its scrap value. Do you understand this now? Are we getting somewhere?

[edit on 4-5-2007 by ben91069]

[edit on 4-5-2007 by ben91069]

Originally posted by ben91069

They did not clean the slag for resale, but I assure you it was recycled. They cleaned it because the slag is not necessary to study the steel as it is scrap.

Is it scrap or evidence? I would assume if they are saving it in a ware house it is evidence and should be left alone.

Originally posted by ben91069

Now, do you have a picture of a cut made with thermite or are you still going to just say stuff without backing it up. Prove that the top picture was made with thermite. Thermite only cuts beams at 45 degree angles? Thermite produces no slag?

Read what I posted again. The first picture = lots of slag (a feature none of the other "cut" beams posess). The first picture = 45 degree "cut" (desirable for demolition, fact).

You could use the thermite shaped linear cutting device to cut at any angle I suppose but 45 degrees is preferred for demolition to allow the upper portion to "slide off".

The company that sells one of the linear cutting devices has no pictures of a cut beam from what I have found. You need a username and password to access their site. However, debunkers have always demanded that a thermite "cut" by nature would be SLOPPY and leave lots of slag. There is a LOT of slag in the first picture...

NONE in the rest. The rest of the pictures show cuts made to remove debris and NO SLAG from the cuts.

This leads me to believe that:

1. The cut in the first picture WAS NOT made using the same equipment use for the other cuts.

2. Someone cleaned the slag off of all the other cut ends (WHY would you do that?)

or

3. The slag just appeared.

I will go with 1.

Since we have pictures of cleanup crews cutting columns with torchs AND I see no slag on the few pictures of the columns after removal that are available AND the first picture has gobs of slag I will take an educated guess and say the first cut was not made with a torch.

Originally posted by ben91069

et me reiterate that slag can be sold as scrap but it is not the primary reason these beams were cleaned, just so you do understand what I am saying and are not tempted to put words into my mouth again that I am saying that the slag was removed just for its scrap value. Do you understand this now? Are we getting somewhere?

No, this is a huge runon sentence I do not understand...

Read as written you are contradicting yourself.

[edit on 4-5-2007 by Pootie]

Originally posted by ben91069

Every single picture shows cut steel processed with a torch

except the first one.

\

Originally posted by ben91069

, and the argument is that the lack of slag shows "somehow" that a torch wasn't used.

No... the oppposite. The lack of slag shows a torch was used... the large amounts of slag may indicate a thermite/thermate cutting device was used.

new topics

-

Russians And Americans At Same Airbase In Niger But Not Sharing Restrooms

World War Three: 2 hours ago -

US Air Force Secretary Kendall flies in cockpit of plane controlled by AI

Aircraft Projects: 7 hours ago -

Messages of Hope – Unity through AI

Dreams & Predictions: 7 hours ago -

Happy Cinco de mayo.

General Chit Chat: 8 hours ago

top topics

-

The BEAST System of Revelation has been awoken and has assumed control, at least since COVID.

New World Order: 12 hours ago, 6 flags -

Happy Cinco de mayo.

General Chit Chat: 8 hours ago, 1 flags -

Messages of Hope – Unity through AI

Dreams & Predictions: 7 hours ago, 1 flags -

US Air Force Secretary Kendall flies in cockpit of plane controlled by AI

Aircraft Projects: 7 hours ago, 1 flags -

Russians And Americans At Same Airbase In Niger But Not Sharing Restrooms

World War Three: 2 hours ago, 1 flags

active topics

-

Really Unexplained

General Chit Chat • 135 • : Beesnestbomber -

Russians And Americans At Same Airbase In Niger But Not Sharing Restrooms

World War Three • 2 • : RussianTroll -

Dugin's interview and the West's complete ignorance of Russia

New World Order • 26 • : Freeborn -

Shocking moment four men 'try to force Jewish pedestrian into car boot' in North London

Breaking Alternative News • 91 • : andy06shake -

Candidate TRUMP Now Has Crazy Judge JUAN MERCHAN After Him - The Stormy Daniels Hush-Money Case.

Political Conspiracies • 1204 • : network dude -

Israeli strikes on southern Gaza city of Rafah kill 22, mostly children, as US advances aid package

Middle East Issues • 153 • : network dude -

SC Jack Smith is Using Subterfuge Tricks with Donald Trumps Upcoming Documents Trial.

Dissecting Disinformation • 129 • : Halfswede -

Happy Cinco de mayo.

General Chit Chat • 8 • : IceHappy -

Messages of Hope – Unity through AI

Dreams & Predictions • 4 • : WhiteRabbitCanada -

Modern Mind Control

General Conspiracies • 39 • : Dreftenq