It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

share:

a reply to: TinySickTears

I can help you out a little there, at least using .obj files.

There are several different 3D model files, but .obj seems to be the best one for compatibility. This is a few of the modellers that can handle .obj:

Some Internet sources for ideas:

I don't think there is anything under the sun you can't find!

TheRedneck

I can help you out a little there, at least using .obj files.

There are several different 3D model files, but .obj seems to be the best one for compatibility. This is a few of the modellers that can handle .obj:

- Autodesk Maya is probably the most powerful, but it has a steep learning curve (I spent two semesters of college learning it and still

barely scratched the surface) and is pricey. Their website shows they have gone to a

subscription format: $190 a month or $1505 a year!

- AC3D is a no frills free (last time I checked) modeller, but it is probably the least powerful of all of them.

- Poser can export .obj, but you really can't do much with creating them inside Poser. Not really a modeller.

- DAZ 3D makes a modelling app called Hexagon. Both are free (but they'll bug you silly trying to sell model files). I just got Hexagon a week or so

ago, and it looks pretty powerful. The GUI looks a lot like Maya, but not quite as many options.

- I think the drafting programs can export .obj files too, like AutoCAD and Solid Works... but if you're making more artistic stuff, that's probably not what you want.

Some Internet sources for ideas:

- Free3D has a good selection based around figures.

- ShareCG has a great selection... I use them a lot for props.

- Renderosity has a pretty good free stuff section. Just don't let some of the regular store prices scare you.

I don't think there is anything under the sun you can't find!

TheRedneck

a reply to: TheRedneck

thanks a lot.

im about to head out to work but when i get home today i will be diving in

thanks a lot.

im about to head out to work but when i get home today i will be diving in

Software I use is usually DesignSpark Mechanical. I love it.

Lots has already been covered.. so ill try to fill in some gaps about actually using it.

First, if you are looking at filament, Delrin is impressive. However, try to get your chops on something like PLA, and expect a curve with other filaments. Sometimes a LARGE curve.

Controlled environments reduce a lot of headaches, and the more controlled the better. Even ones that come enclosed can frequently benefit from some hacking.

A good test and learning phase can be printing parts and mods for your printer. Done right, you learn alongside improving your equipment.

And, keep your eyes on places like MIT. Their multimaterial printers are ULTRA fascinating. The possibility of being able to do something like print your own PCB in its entirety is extremely appealing to someone like me (and you too Red, from what I remember).

Lots has already been covered.. so ill try to fill in some gaps about actually using it.

First, if you are looking at filament, Delrin is impressive. However, try to get your chops on something like PLA, and expect a curve with other filaments. Sometimes a LARGE curve.

Controlled environments reduce a lot of headaches, and the more controlled the better. Even ones that come enclosed can frequently benefit from some hacking.

A good test and learning phase can be printing parts and mods for your printer. Done right, you learn alongside improving your equipment.

And, keep your eyes on places like MIT. Their multimaterial printers are ULTRA fascinating. The possibility of being able to do something like print your own PCB in its entirety is extremely appealing to someone like me (and you too Red, from what I remember).

a reply to: Serdgiam

can you give me a link for an instructional on where to start for a total beginner?

assume i have the da vinci pro. looking like i am going to go that way.

i see how i can download an stl from thingiverse and send to my printer

i see how i can scan an object and send it to my printer

lets say though i want to print a small chess piece or something simple and i have no file and i need to open up the software and model it myself...

how would i do that?

thank you

can you give me a link for an instructional on where to start for a total beginner?

assume i have the da vinci pro. looking like i am going to go that way.

i see how i can download an stl from thingiverse and send to my printer

i see how i can scan an object and send it to my printer

lets say though i want to print a small chess piece or something simple and i have no file and i need to open up the software and model it myself...

how would i do that?

thank you

a reply to: TinySickTears

Honestly, I would suggest YouTube. Your actual printer wont be quite is important as all the steps leading up to the actual print.

So, if you are already familiar and comfortable with the design software of your choice, that's probably one of the biggest steps. Then comes the slicing, which is where you will do things like figure out wall thicknesses and infill. This design work is critical in the end product, as the objects will tend to break along layers under force, detail better with different orientations, etc.

When it comes to printing, its going to be all about finding the right temps and environmental variables, which in a lot of cases can be specific to you and your setup. Instead of thinking about it in terms of the specific manufacturer, think more in terms that this is all a general process much like CNC. So, model specific info may be a bit more relevant once you have the general basics down.

I actually hesitate a bit to give specific recommendations. As annoying as that may be, this is a REALLY open ended endeavor that in learning, you personally may come across something neat and novel.

That said, here and here are good intros. Beyond that, do searches like '3d printing 101' and take in as much info as you can. There is a lot, and much of it will be up to you.

Best advice is PRINT! I have some thousands of km of filament under my belt and would still consider myself a beginner. This is a good time to get into though, since it will force the user to understand things that they wouldn't need to in a few, or more, years. But, its still immensely useful...

Honestly, I would suggest YouTube. Your actual printer wont be quite is important as all the steps leading up to the actual print.

So, if you are already familiar and comfortable with the design software of your choice, that's probably one of the biggest steps. Then comes the slicing, which is where you will do things like figure out wall thicknesses and infill. This design work is critical in the end product, as the objects will tend to break along layers under force, detail better with different orientations, etc.

When it comes to printing, its going to be all about finding the right temps and environmental variables, which in a lot of cases can be specific to you and your setup. Instead of thinking about it in terms of the specific manufacturer, think more in terms that this is all a general process much like CNC. So, model specific info may be a bit more relevant once you have the general basics down.

I actually hesitate a bit to give specific recommendations. As annoying as that may be, this is a REALLY open ended endeavor that in learning, you personally may come across something neat and novel.

That said, here and here are good intros. Beyond that, do searches like '3d printing 101' and take in as much info as you can. There is a lot, and much of it will be up to you.

Best advice is PRINT! I have some thousands of km of filament under my belt and would still consider myself a beginner. This is a good time to get into though, since it will force the user to understand things that they wouldn't need to in a few, or more, years. But, its still immensely useful...

edit on 20-6-2018 by Serdgiam because: (no reason given)

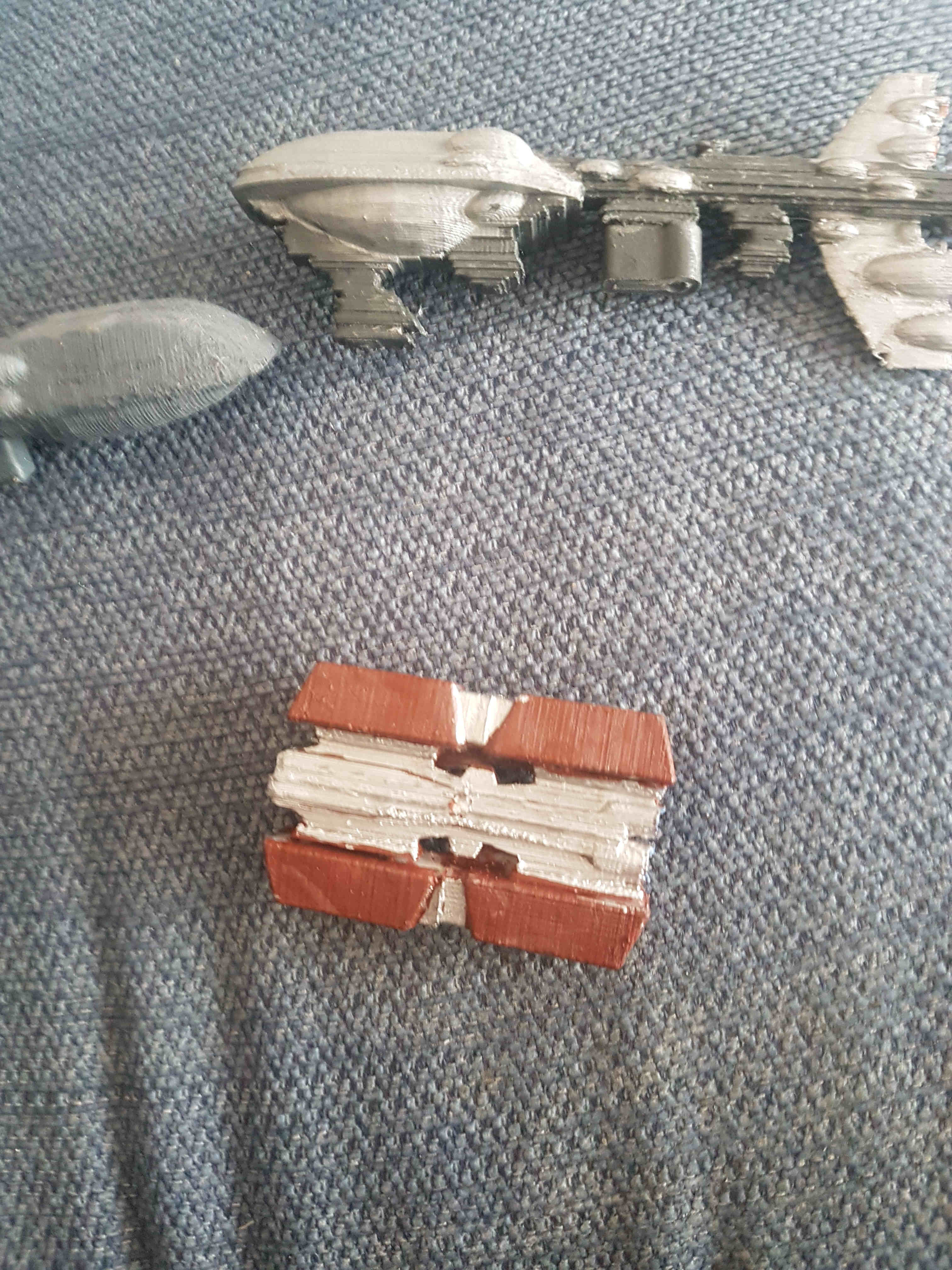

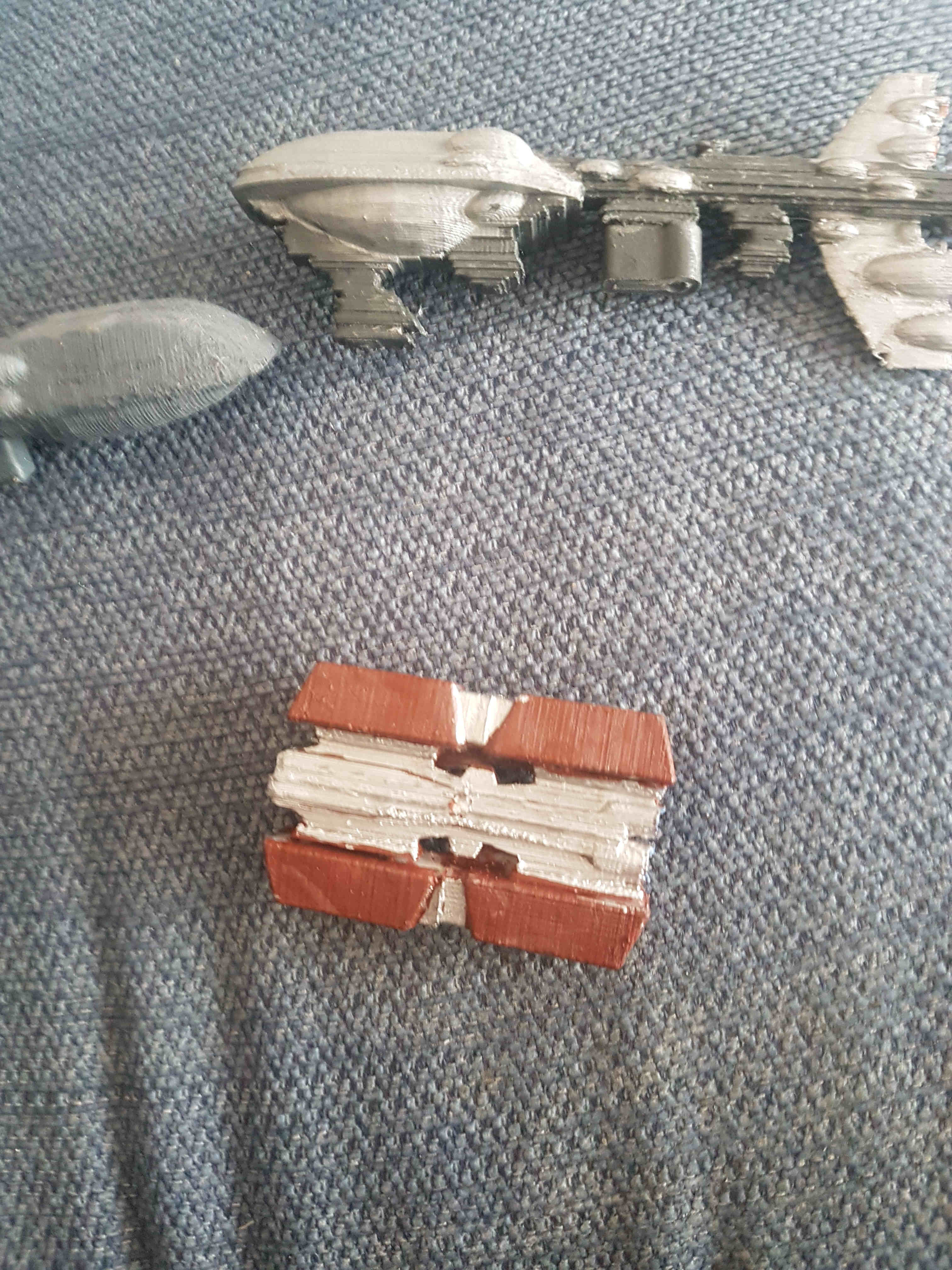

Hi as promised my models these where done with the filament printer.

They are ships from the Tie fighter games.

Problem is my bad painting.

The dreadnought cruiser (lower one) was done on a high getting 2mm so the detail not as good.

I cant seem the find the SLA models....

They are ships from the Tie fighter games.

Problem is my bad painting.

The dreadnought cruiser (lower one) was done on a high getting 2mm so the detail not as good.

I cant seem the find the SLA models....

edit on 22-6-2018 by DieGloke because: (no reason given)

a reply to: Serdgiam

I'll admit, printing PCBs was once a kind of ultimate goal for me. A couple family members now have laser engravers, and I spent an appreciable amount of time trying to figure out how to get a PCB out of them. But in the end, I don't think I can reasonably beat what I have now: I use a company called PCBway out of China that does an excellent job at a reasonable price. As an example, I just ordered 5 boards that are 4-layer, 9" square, and the cost including shipping was $214... the only way I could get more complex would be something like a custom motherboard for a PC! And while I was at it, I ordered 10 0.8" x 2.4" 2-layer breakout boards for another project for just an additional $5. I get about a week turnaround, and the boards are always perfect. Plus, the software I use (an old copy of Altium Designer) is made specifically for PCB design. I can have one project being assembled while another is being designed, since either computer will run Altium.

That's a pretty sweet setup there, IMO... hard to beat, even with a 3D printer. I highly recommend PCBway.

But for mechanical parts... that's where a 3D printer will shine!

TheRedneck

I'll admit, printing PCBs was once a kind of ultimate goal for me. A couple family members now have laser engravers, and I spent an appreciable amount of time trying to figure out how to get a PCB out of them. But in the end, I don't think I can reasonably beat what I have now: I use a company called PCBway out of China that does an excellent job at a reasonable price. As an example, I just ordered 5 boards that are 4-layer, 9" square, and the cost including shipping was $214... the only way I could get more complex would be something like a custom motherboard for a PC! And while I was at it, I ordered 10 0.8" x 2.4" 2-layer breakout boards for another project for just an additional $5. I get about a week turnaround, and the boards are always perfect. Plus, the software I use (an old copy of Altium Designer) is made specifically for PCB design. I can have one project being assembled while another is being designed, since either computer will run Altium.

That's a pretty sweet setup there, IMO... hard to beat, even with a 3D printer. I highly recommend PCBway.

But for mechanical parts... that's where a 3D printer will shine!

TheRedneck

a reply to: TinySickTears

For a total beginner, I'd say get your software running first. There is a learning curve, and I'd think it would be steeper for the software than for the printer.

I don't use it much myself, since I have a copy of PoserPro 2010, but DAZ 3D makes an excellent 3D animation/rendering setup, and it's free! They also have a free fully functional program for modelling (what you;re most interested in) called hexagon available. They make their money from models users make and sell through their store, not from the software itself. You can download a free, fully functional copy of both DAZ 3D and Hexagon here.

There are loads of Hexagon tutorials online and on YouTube. You'll likely spend a couple weeks learning how to create 3D models, and the advantage of having DAZ 3D is you can import them and render them to see how they will (theoretically) look.

If memory serves, you'll have to set up a free account and download their downloader/installer.

I'd stick with .obj file creation... it's the easiest and works pretty much across the board...unless you get the animation bug like me. I have seen some pretty nice work coming out of DAZ 3D.

TheRedneck

For a total beginner, I'd say get your software running first. There is a learning curve, and I'd think it would be steeper for the software than for the printer.

I don't use it much myself, since I have a copy of PoserPro 2010, but DAZ 3D makes an excellent 3D animation/rendering setup, and it's free! They also have a free fully functional program for modelling (what you;re most interested in) called hexagon available. They make their money from models users make and sell through their store, not from the software itself. You can download a free, fully functional copy of both DAZ 3D and Hexagon here.

There are loads of Hexagon tutorials online and on YouTube. You'll likely spend a couple weeks learning how to create 3D models, and the advantage of having DAZ 3D is you can import them and render them to see how they will (theoretically) look.

If memory serves, you'll have to set up a free account and download their downloader/installer.

I'd stick with .obj file creation... it's the easiest and works pretty much across the board...unless you get the animation bug like me. I have seen some pretty nice work coming out of DAZ 3D.

TheRedneck

a reply to: DieGloke

OK, those are awesome! Is that the 100 micron resolution?

I am seeing a little deviation from the layer resolution, but it's not that bad... looks like something that a few minutes with some extra-fine sandpaper would take out easily enough.

Thank you!

TheRedneck

OK, those are awesome! Is that the 100 micron resolution?

I am seeing a little deviation from the layer resolution, but it's not that bad... looks like something that a few minutes with some extra-fine sandpaper would take out easily enough.

Thank you!

TheRedneck

a reply to: TheRedneck

Its still a goal for me Even though I've pretty much moved on from those "aspirations of yore." My health issues are simply insurmountable, sadly.

BUT! Seriously check it out:

multifab

My concept was to actually do away with PCBs entirely and instead embed the entire circuit(s) into the structure of the device itself.

I can assume some issues with it right off the bat (everything from heat dissipation to replacements), but at the very least I could do away with some wiring by having conductive material with some type of plug at the end.

ETA: Also, a good general tip is to power your printer through a battery backup. Even ones with a "resume" function can be problematic and there are few things worse than getting to hour 50 of a 60 print and getting a power blip.

Its still a goal for me Even though I've pretty much moved on from those "aspirations of yore." My health issues are simply insurmountable, sadly.

BUT! Seriously check it out:

multifab

My concept was to actually do away with PCBs entirely and instead embed the entire circuit(s) into the structure of the device itself.

I can assume some issues with it right off the bat (everything from heat dissipation to replacements), but at the very least I could do away with some wiring by having conductive material with some type of plug at the end.

ETA: Also, a good general tip is to power your printer through a battery backup. Even ones with a "resume" function can be problematic and there are few things worse than getting to hour 50 of a 60 print and getting a power blip.

edit on 22-6-2018 by Serdgiam because: (no reason

given)

a reply to: TheRedneck

Depending on the material, you can also do things like acetone vapor baths. Pretty clean results that way.

DieGlocke, any specific reason for that orientation?

Depending on the material, you can also do things like acetone vapor baths. Pretty clean results that way.

DieGlocke, any specific reason for that orientation?

a reply to: Serdgiam

OOOH! Redneck LIKE! Redneck like a LOT!

I've never really been tied to PCB construction myself. It is usually the best way to assemble a circuit, but not always. I'm very open to other techniques. Direct embeddment might be an interesting concept.

I caught that hour 50 of 60 remark... does it take that long? If so, I'm looking at a repeat of what I do in my 3D animation work. I will constantly be working on a scene while I do other things (I have to break from time to time and do something else or I will have neurons threatening to strike). That's when I work on 3D for an hour or so. Then, when I close up shop for the night, I figure how long it will be before I expect to be back, figure how many frames of video that equates to, and set up a run. Usually during the summer it is an overnight run, but I have set it to run for several days.

When I set it, I restrict Poser to 5 of the 6 cores... little real difference in cutting time, but I can log in remotely with one core idle and access files.

The problem comes in when I set those long runs and the power blinks after a few days of running, like you mention with the printer. Poser writes the movie file in real time, but usually the last frame is corrupted and I don't know how many frames it ran... so I just scrap it and reset the cut. On a printer, that would cost me money, because you can't turn the shape back into filament very easily.

So yeah... I have been considering setting up a "poor man's UPS"... just build a simple charger and hook up an inverter to a marine battery. Of course, the batteries are getting nearly as expensive as UPS's, so....

I hadn't thought about acetone... great idea! I keep some in the shop for plastic cleanup anyway.

TheRedneck

OOOH! Redneck LIKE! Redneck like a LOT!

I've never really been tied to PCB construction myself. It is usually the best way to assemble a circuit, but not always. I'm very open to other techniques. Direct embeddment might be an interesting concept.

I caught that hour 50 of 60 remark... does it take that long? If so, I'm looking at a repeat of what I do in my 3D animation work. I will constantly be working on a scene while I do other things (I have to break from time to time and do something else or I will have neurons threatening to strike). That's when I work on 3D for an hour or so. Then, when I close up shop for the night, I figure how long it will be before I expect to be back, figure how many frames of video that equates to, and set up a run. Usually during the summer it is an overnight run, but I have set it to run for several days.

When I set it, I restrict Poser to 5 of the 6 cores... little real difference in cutting time, but I can log in remotely with one core idle and access files.

The problem comes in when I set those long runs and the power blinks after a few days of running, like you mention with the printer. Poser writes the movie file in real time, but usually the last frame is corrupted and I don't know how many frames it ran... so I just scrap it and reset the cut. On a printer, that would cost me money, because you can't turn the shape back into filament very easily.

So yeah... I have been considering setting up a "poor man's UPS"... just build a simple charger and hook up an inverter to a marine battery. Of course, the batteries are getting nearly as expensive as UPS's, so....

I hadn't thought about acetone... great idea! I keep some in the shop for plastic cleanup anyway.

TheRedneck

a reply to: TheRedneck

I only really look at PCB for that "finished and clean" look, and it does provide that. But really, for a lot of applications, I'm not convinced showing off those internals is needed (or even prudent in some cases). Love the finished product on my headphone amp though! Though, I used nice perfboard.

So, I doubt that 50+ hour print times are at all average. I was trying to print a bunch of stuff all at once, on multiple layers. It would have worked too, if it weren't for those meddling something or others..

20-30 hour max is probably closer to normal with 4-12 hour print times being average. That's an admittedly large range for an 'average,' but prints can vary wildly. An object with fat layers and no infill will go significantly faster than a solid object with thin layers. Most slicing software will give a pretty good estimate as you adjust those variables though.

I really have liked having this UPS. I basically connect it to whatever system I'm concerned about and it does its thing. Priced pretty reasonably too, in my beggars opinion.

I'm the type that salvages 18650s (they're so ubiquitous and useful), but felt getting that UPS was actually a better investment than using my time to build one. YMMV, of course

I only really look at PCB for that "finished and clean" look, and it does provide that. But really, for a lot of applications, I'm not convinced showing off those internals is needed (or even prudent in some cases). Love the finished product on my headphone amp though! Though, I used nice perfboard.

So, I doubt that 50+ hour print times are at all average. I was trying to print a bunch of stuff all at once, on multiple layers. It would have worked too, if it weren't for those meddling something or others..

20-30 hour max is probably closer to normal with 4-12 hour print times being average. That's an admittedly large range for an 'average,' but prints can vary wildly. An object with fat layers and no infill will go significantly faster than a solid object with thin layers. Most slicing software will give a pretty good estimate as you adjust those variables though.

I really have liked having this UPS. I basically connect it to whatever system I'm concerned about and it does its thing. Priced pretty reasonably too, in my beggars opinion.

I'm the type that salvages 18650s (they're so ubiquitous and useful), but felt getting that UPS was actually a better investment than using my time to build one. YMMV, of course

a reply to: Serdgiam

You actually made me take a look at the 18650s again. It would take 52 of them to equal the capacity of one average lead-acid battery, but that is still cheaper. Only downside is that I would have 52 possible failures instead of one.

Of course, I had to check the power requirements for a printer. Turns out 100-200W seems a reasonable average. That's at worst one third of what I was figuring for a computer supply. We actually have very good power here, it does blink out moderately often, but the typical outage lasts under 5 minutes. It the power goes out for more than 2 hours, it is a major issue they're having to deal with. Of course, a one-second blink is as bad where the computer is concerned as a 7-day outage.

Good to hear about the print times... that did have me a little concerned. The computer is designed to run 24/7, but I don't know about a printer... so many mechanical issues that can pop up.

I started this thread thinking all printers would probably take .obj files, but I noticed a lot of them seem to want .stl files. What's your experience using .obj?

TheRedneck

You actually made me take a look at the 18650s again. It would take 52 of them to equal the capacity of one average lead-acid battery, but that is still cheaper. Only downside is that I would have 52 possible failures instead of one.

Of course, I had to check the power requirements for a printer. Turns out 100-200W seems a reasonable average. That's at worst one third of what I was figuring for a computer supply. We actually have very good power here, it does blink out moderately often, but the typical outage lasts under 5 minutes. It the power goes out for more than 2 hours, it is a major issue they're having to deal with. Of course, a one-second blink is as bad where the computer is concerned as a 7-day outage.

Good to hear about the print times... that did have me a little concerned. The computer is designed to run 24/7, but I don't know about a printer... so many mechanical issues that can pop up.

I started this thread thinking all printers would probably take .obj files, but I noticed a lot of them seem to want .stl files. What's your experience using .obj?

TheRedneck

a reply to: TheRedneck

52 possible points of failure AND 52 individual cells to manage voltage. But, given the fact you can grab them from laptop batteries to tool batteries.. pretty hard to ignore. Just remember, many of them throw out 10+ amps! I know that number means something to you, and its not a rating to be taken lightly.

In most packs, like laptops, they generally stop charging when a single unit craps out due to the design of the circuit. So, we can usually nab about 10 good cells from an extended pack that is "dead."

Also remember with the PC power supply, they only pull what they need (I know you know).. so a build that is actually pulling 600w is.. lets say "rare." Mine pulls ~200w (iirc) with a 1070ti, 2700k, and water cooling with everything overclocked. Also, if you need any help with specific parts, let me know. I know yer good on the electrical side, but specific arenas are always a bit different aminal (proper spelling, btw).

The issues with long runs on a printer are almost exclusively environmental. They are shockingly reliable mechanically. After thousands of km of filament, my only issue was the thermistor crapping out. An easy fix, though I've really been focusing on the guitar stuff so I haven't gotten to it.

As for file differences, I actually haven't messed with .obj much. My understanding though is that it has some superior qualities which may make it a better format. However, as far as I know, either one will frequently be converted to gcode for the actual print, so it might be a bit moot.

52 possible points of failure AND 52 individual cells to manage voltage. But, given the fact you can grab them from laptop batteries to tool batteries.. pretty hard to ignore. Just remember, many of them throw out 10+ amps! I know that number means something to you, and its not a rating to be taken lightly.

In most packs, like laptops, they generally stop charging when a single unit craps out due to the design of the circuit. So, we can usually nab about 10 good cells from an extended pack that is "dead."

Also remember with the PC power supply, they only pull what they need (I know you know).. so a build that is actually pulling 600w is.. lets say "rare." Mine pulls ~200w (iirc) with a 1070ti, 2700k, and water cooling with everything overclocked. Also, if you need any help with specific parts, let me know. I know yer good on the electrical side, but specific arenas are always a bit different aminal (proper spelling, btw).

The issues with long runs on a printer are almost exclusively environmental. They are shockingly reliable mechanically. After thousands of km of filament, my only issue was the thermistor crapping out. An easy fix, though I've really been focusing on the guitar stuff so I haven't gotten to it.

As for file differences, I actually haven't messed with .obj much. My understanding though is that it has some superior qualities which may make it a better format. However, as far as I know, either one will frequently be converted to gcode for the actual print, so it might be a bit moot.

a reply to: Serdgiam

Of course, given my propensity to make things much more complex than they need be, I could easily rig up something to do some automatic switching should a dead cell be detected. That's actually not a bad idea.

(OK, maybe it is, but that's never stopped me before, lol)

Sounds like a nice machine. I'm running a 1090T with 16 GB DDR3 RAM and twin 7200 RPM TB drives. It pushes a 600W power supply, mainly when cutting video, but as you say that is not necessarily continuous power. (I just recently had to upgrade to a 750W... wore the old 600W out out trying to keep up.) I just don't like underestimating power requirements, so I always figure worst case.

BTW, my motherboard has overclocking (an older ASUS board) built in... I've never tried it. As it is, with 5 cores at 100% for extended periods, I run about 52-53 degrees C during the summer. I was wondering what kind of temperature increase you were getting with the overclocking?

I shouldn't have any issues with environment if I am able to pull off what I am thinking. I've somehow managed to get WiFi to cover a couple acres here. with my shop at the extreme end but connected through a Signal King adapter. I have a small spare room in my house that would make a great place for a mini-office, printer, and 3d printer, and it is temperature-controlled and fairly dust-free (except for my smokes of course). As long as I get a printer that is WiFi enabled, it should work perfectly, since it is pretty close to my network hub area.

The only drawback is walking back and forth to get a part... but with a print time measured in a couple of hours, that isn't really a big deal. Just a little logistics consideration.

I'm seeing references to G-code.. my son (CNC machinist) is constantly talking about G-code, and seeing 3D printing appears to be an offshoot of CNC, I am assuming it is a variation of what he uses. If so, if the printer actually uses G-code, then any app that would slice the object bring printed and convert it should work. That alleviates a lot of my concern there.

I am starting to scale back my original plans. I'm looking at one of the smaller machines now, in the range of a few hundred dollars, just to give me a chance to get started with 3D printing. TinySickTears may actually have an advantage over me in some respects, being totally unfamiliar with 3D: I am likely to have some built-in biases from my previous work that don't carry over well to the printing. A cheaper machine to start with might be a good way to overcome those without spending too much cash up front.

I did something similar with my Smithy. I bought a Midas 1220, their low-end model, while what I thought I wanted was one of the larger Granite models. As it turns out, I am NOT a machinist! I cannot touch the capability of the Midas unit, and my son is very good about pitching in to help me with more complex parts... so I'm better off with the smaller machine shop where I can just handle small jobs in house.

Same thing with welding. I have a nice, smaller Lincoln MIG that does a great job, much more than I am capable of doing. I can run a bead... an ugly bead, but a bead... so I don't need a bigger, fancier machine. It would be a waste of money. As it is, the grinding is about as expensive as the welding for me, trying to grind off all that excess metal, lol.

TheRedneck

52 possible points of failure AND 52 individual cells to manage voltage. But, given the fact you can grab them from laptop batteries to tool batteries.. pretty hard to ignore. Just remember, many of them throw out 10+ amps! I know that number means something to you, and its not a rating to be taken lightly.

Of course, given my propensity to make things much more complex than they need be, I could easily rig up something to do some automatic switching should a dead cell be detected. That's actually not a bad idea.

(OK, maybe it is, but that's never stopped me before, lol)

Also remember with the PC power supply, they only pull what they need (I know you know).. so a build that is actually pulling 600w is.. lets say "rare." Mine pulls ~200w (iirc) with a 1070ti, 2700k, and water cooling with everything overclocked.

Sounds like a nice machine. I'm running a 1090T with 16 GB DDR3 RAM and twin 7200 RPM TB drives. It pushes a 600W power supply, mainly when cutting video, but as you say that is not necessarily continuous power. (I just recently had to upgrade to a 750W... wore the old 600W out out trying to keep up.) I just don't like underestimating power requirements, so I always figure worst case.

BTW, my motherboard has overclocking (an older ASUS board) built in... I've never tried it. As it is, with 5 cores at 100% for extended periods, I run about 52-53 degrees C during the summer. I was wondering what kind of temperature increase you were getting with the overclocking?

The issues with long runs on a printer are almost exclusively environmental. They are shockingly reliable mechanically. After thousands of km of filament, my only issue was the thermistor crapping out. An easy fix, though I've really been focusing on the guitar stuff so I haven't gotten to it.

I shouldn't have any issues with environment if I am able to pull off what I am thinking. I've somehow managed to get WiFi to cover a couple acres here. with my shop at the extreme end but connected through a Signal King adapter. I have a small spare room in my house that would make a great place for a mini-office, printer, and 3d printer, and it is temperature-controlled and fairly dust-free (except for my smokes of course). As long as I get a printer that is WiFi enabled, it should work perfectly, since it is pretty close to my network hub area.

The only drawback is walking back and forth to get a part... but with a print time measured in a couple of hours, that isn't really a big deal. Just a little logistics consideration.

As for file differences, I actually haven't messed with .obj much. My understanding though is that it has some superior qualities which may make it a better format. However, as far as I know, either one will frequently be converted to gcode for the actual print, so it might be a bit moot.

I'm seeing references to G-code.. my son (CNC machinist) is constantly talking about G-code, and seeing 3D printing appears to be an offshoot of CNC, I am assuming it is a variation of what he uses. If so, if the printer actually uses G-code, then any app that would slice the object bring printed and convert it should work. That alleviates a lot of my concern there.

I am starting to scale back my original plans. I'm looking at one of the smaller machines now, in the range of a few hundred dollars, just to give me a chance to get started with 3D printing. TinySickTears may actually have an advantage over me in some respects, being totally unfamiliar with 3D: I am likely to have some built-in biases from my previous work that don't carry over well to the printing. A cheaper machine to start with might be a good way to overcome those without spending too much cash up front.

I did something similar with my Smithy. I bought a Midas 1220, their low-end model, while what I thought I wanted was one of the larger Granite models. As it turns out, I am NOT a machinist! I cannot touch the capability of the Midas unit, and my son is very good about pitching in to help me with more complex parts... so I'm better off with the smaller machine shop where I can just handle small jobs in house.

Same thing with welding. I have a nice, smaller Lincoln MIG that does a great job, much more than I am capable of doing. I can run a bead... an ugly bead, but a bead... so I don't need a bigger, fancier machine. It would be a waste of money. As it is, the grinding is about as expensive as the welding for me, trying to grind off all that excess metal, lol.

TheRedneck

a reply to: TheRedneck

IIRC, the 1090t has a TDP of 125w. Super hungry processor

Have you tried a solid state hard drive yet? They are.. pretty damn nice.

My temps are currently right around yours (~50c) with an ambient temp of 25-27c. I actually didn't see more than maybe 5c increase with the OC. I'm pretty obsessed with efficiency though, so my focus was getting the highest OC possible with roughly stock voltage. On clients PCs, I also will frequently keep stock speeds but lower voltages (if they want, of course).

As far as environmental concerns, prints can be EXTREMELY sensitive to changes. I can literally blow on a corner of the object a few times and ruin the print.

The ideal is 100% consistency in the build area, from air flow to humidity to temp. That ideal isn't possible, but the closer we can get, the better!

I think its a good idea to start a bit smaller. Everything is pretty much the same, except controlling the environment. It simply becomes more difficult with a bigger build chamber. Its also good to keep in mind that many projects can be split into different prints. I struggle with that one, constantly trying to get the whole project printed in a single run..

If your son is a machinist, definitely bring him in on it. Its pretty much the same thing, with one process being additive and the other subtractive. Also, for fun, look into 'additive manufacturing' and 'lights out manufacturing.'

Welding is something I really, really want to learn. I doubt I can with my back, but that's one of those tools and skills that enables the user to build incredible things.

IIRC, the 1090t has a TDP of 125w. Super hungry processor

Have you tried a solid state hard drive yet? They are.. pretty damn nice.

My temps are currently right around yours (~50c) with an ambient temp of 25-27c. I actually didn't see more than maybe 5c increase with the OC. I'm pretty obsessed with efficiency though, so my focus was getting the highest OC possible with roughly stock voltage. On clients PCs, I also will frequently keep stock speeds but lower voltages (if they want, of course).

As far as environmental concerns, prints can be EXTREMELY sensitive to changes. I can literally blow on a corner of the object a few times and ruin the print.

The ideal is 100% consistency in the build area, from air flow to humidity to temp. That ideal isn't possible, but the closer we can get, the better!

I think its a good idea to start a bit smaller. Everything is pretty much the same, except controlling the environment. It simply becomes more difficult with a bigger build chamber. Its also good to keep in mind that many projects can be split into different prints. I struggle with that one, constantly trying to get the whole project printed in a single run..

If your son is a machinist, definitely bring him in on it. Its pretty much the same thing, with one process being additive and the other subtractive. Also, for fun, look into 'additive manufacturing' and 'lights out manufacturing.'

Welding is something I really, really want to learn. I doubt I can with my back, but that's one of those tools and skills that enables the user to build incredible things.

She likes the power, but when it comes to number crunching... AMD is just hard to beat. At the time, the 1090t was one step down from their most

powerful processor, by something like 100 MHz clock speed. The price difference was a couple hundred bucks, so I went with the number two spot.

My biggest disadvantage with my shop is it is not temperature-controlled. I have a wood heater for the winter, along with a bottle-top propane heater, and in the summer I use an old freestanding heat pump and fans (I can handle the heat much better than I can the cold). So it doesn't sound like the optimal environment for a 3-D printer.

On the other hand, my house has a new high-efficiency heat pump, and the room I was planning on using is heated/cooled, has a door to it, and is in the middle of the house. It probably has the best possible conditions I can imagine for consistency in environment. So it looks like that will be the plan. Set it to run, close the door, and wait. If the printer is accessible via WiFi (which I am sure it is) I can log in and see if it's finished or not.

I am also planning on setting up another (smaller) PC in that room... add in a cheap webcam pointed at the printer and I can even get visuals by remoting in. TeamViewer is awesome!

I'm sure my boy will be involved... 3D printing is something he is in love with! He already has a Chinese laser engraver that he plays with. I actually thought at one point about getting him to do PCBs for me, but the process is a little clumsy: you have to use flat black paint on the board and set the laser to remove the paint, then etch it. Copper dissipates heat far too fast to just etch off the copper.

Welding isn't that hard. I spent maybe $450 IIRC on a small Lincoln MIG, and another $100 on a self-darkening helmet. I finally ran through the small spool of wire that came with it, and put in a large spool... I'm nowhere near finishing it. When I put in the wood heater I mentioned, I made my own temporary flue, and I needed something to hold the pipe off the eave outside. I just got some scrap steel I had, cut it on my chop saw to the right lengths, clamped it together with a couple C-clamps and vise-grips, and started welding. An hour later I had something that worked great.

It's a little like soldering, but with much more heat and on a much larger scale. The trick is to make small figure 8s with the tip as you move down and let the molten steel follow you, just like letting solder flow across a joint. You want to actually melt into the base metal a little, though, on both pieces, just not enough to burn all the way through, lol. And like soldering, it takes practice.

I definitely recommend getting one of those self-darkening helmets. The one I have works great! I can still see what I am doing until I hit the arc, then everything except the arc goes dark.

Oh, and watch for splatter... those little balls of molten steel are sorta on the warm side.

TheRedneck

My biggest disadvantage with my shop is it is not temperature-controlled. I have a wood heater for the winter, along with a bottle-top propane heater, and in the summer I use an old freestanding heat pump and fans (I can handle the heat much better than I can the cold). So it doesn't sound like the optimal environment for a 3-D printer.

On the other hand, my house has a new high-efficiency heat pump, and the room I was planning on using is heated/cooled, has a door to it, and is in the middle of the house. It probably has the best possible conditions I can imagine for consistency in environment. So it looks like that will be the plan. Set it to run, close the door, and wait. If the printer is accessible via WiFi (which I am sure it is) I can log in and see if it's finished or not.

I am also planning on setting up another (smaller) PC in that room... add in a cheap webcam pointed at the printer and I can even get visuals by remoting in. TeamViewer is awesome!

I'm sure my boy will be involved... 3D printing is something he is in love with! He already has a Chinese laser engraver that he plays with. I actually thought at one point about getting him to do PCBs for me, but the process is a little clumsy: you have to use flat black paint on the board and set the laser to remove the paint, then etch it. Copper dissipates heat far too fast to just etch off the copper.

Welding isn't that hard. I spent maybe $450 IIRC on a small Lincoln MIG, and another $100 on a self-darkening helmet. I finally ran through the small spool of wire that came with it, and put in a large spool... I'm nowhere near finishing it. When I put in the wood heater I mentioned, I made my own temporary flue, and I needed something to hold the pipe off the eave outside. I just got some scrap steel I had, cut it on my chop saw to the right lengths, clamped it together with a couple C-clamps and vise-grips, and started welding. An hour later I had something that worked great.

It's a little like soldering, but with much more heat and on a much larger scale. The trick is to make small figure 8s with the tip as you move down and let the molten steel follow you, just like letting solder flow across a joint. You want to actually melt into the base metal a little, though, on both pieces, just not enough to burn all the way through, lol. And like soldering, it takes practice.

I definitely recommend getting one of those self-darkening helmets. The one I have works great! I can still see what I am doing until I hit the arc, then everything except the arc goes dark.

Oh, and watch for splatter... those little balls of molten steel are sorta on the warm side.

TheRedneck

new topics

-

Scientists assaulted at Skinwalker Ranch (Bigelow era)

Aliens and UFOs: 32 minutes ago -

Cool video of bees protecting other bugs

General Chit Chat: 1 hours ago -

The horse

Jokes, Puns, & Pranks: 2 hours ago -

Mods Are Sleeping: Let's Post Protists!

General Chit Chat: 2 hours ago -

1st Jewish Biden Appointee to Resign Over Gaza Quits on Nakba Day

Political Issues: 7 hours ago -

Support call for digital id and banking

New World Order: 9 hours ago -

I am now Greater by having been made Lesser.

Religion, Faith, And Theology: 9 hours ago

top topics

-

Why did Michael Cohen Need the Secret Service to Deal with a 14yr. Old Boy?

US Political Madness: 15 hours ago, 13 flags -

65 percent of young British Muslims oppose Israel’s right to exist - shocking new poll...

Conspiracies in Religions: 17 hours ago, 8 flags -

Cool video of bees protecting other bugs

General Chit Chat: 1 hours ago, 8 flags -

Support call for digital id and banking

New World Order: 9 hours ago, 8 flags -

UFO data deadline set for federal agencies - September 30 2024

Aliens and UFOs: 12 hours ago, 7 flags -

I shot JFK..

Jokes, Puns, & Pranks: 12 hours ago, 6 flags -

1st Jewish Biden Appointee to Resign Over Gaza Quits on Nakba Day

Political Issues: 7 hours ago, 5 flags -

Mods Are Sleeping: Let's Post Protists!

General Chit Chat: 2 hours ago, 4 flags -

I am now Greater by having been made Lesser.

Religion, Faith, And Theology: 9 hours ago, 2 flags -

The horse

Jokes, Puns, & Pranks: 2 hours ago, 1 flags

active topics

-

Scientists assaulted at Skinwalker Ranch (Bigelow era)

Aliens and UFOs • 2 • : marg6043 -

The biggest problem with the Hush money trial

US Political Madness • 455 • : xuenchen -

Biden accepts Trumps debate challenge

2024 Elections • 150 • : Annee -

Cool video of bees protecting other bugs

General Chit Chat • 4 • : rickymouse -

Killings of Palestinian children are soaring in the West Bank.

World War Three • 189 • : KrustyKrab -

You and yer sodium.

Medical Issues & Conspiracies • 16 • : KnowItAllKnowNothin -

Gaza Genocide Real or Propaganda

Middle East Issues • 608 • : cherokeetroy -

I shot JFK..

Jokes, Puns, & Pranks • 29 • : Oldcarpy2 -

1st Jewish Biden Appointee to Resign Over Gaza Quits on Nakba Day

Political Issues • 67 • : marg6043 -

Don’t Obstruct the Leftist Implosion

US Political Madness • 41 • : marg6043