It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

share:

Originally posted by roguetechie

reply to post by ziplock9000

That's not entirely true... by taking exhaust waste heat out of a tailpipe and doing it in a way that doesn't increase backpressure you would be able to extract energy without any "cost". The energy is already there it's just a matter of finding a way to extract it.

If thermodynamics actually worked that way the entire cogeneration industry would not exist. Actually if thermodynamics worked that way about half the stuff you use on a weekly basis wouldn't work.

That's my point exactly.. It's not possible without adding back pressure.

You can certainly reduce the effect, but you cant eliminate it.

Now if the cost of back pressure in extra gas consumption is more than the output energy, then the device is unusable.

Question - Do you know of any existing heat transfer devices for exhaust systems that have very little friction and cause negligible back pressure? I'd imagine it would be some sort of micro heat sink arrangement, but increasing thermal transfer area also increases friction. (Honest question, I'm not being an ass)

reply to post by ziplock9000

Explanation: REALLY!

How about you think OUTSIDE THE PIPE ok!

The outside of exhaust pipe is MORE than hot enough to do the job without increasing back pressure in the pipe.

By the time the energy has left the outside of the pipe it is LOST to the atmosphere .. we are only collecting that before it is radiated away ok!

Personal Disclosure: Also this is not a perfect 100% energy efficient design and we dont claim it is! It is not over unity ... we are however using open system designs ... it is not a 100% closed system and so you can take the worry over the law of thermodynamics and burn them ok!

Explanation: REALLY!

How about you think OUTSIDE THE PIPE ok!

The outside of exhaust pipe is MORE than hot enough to do the job without increasing back pressure in the pipe.

By the time the energy has left the outside of the pipe it is LOST to the atmosphere .. we are only collecting that before it is radiated away ok!

Personal Disclosure: Also this is not a perfect 100% energy efficient design and we dont claim it is! It is not over unity ... we are however using open system designs ... it is not a 100% closed system and so you can take the worry over the law of thermodynamics and burn them ok!

If you were thinking of attaching this to some kind of engine, realistically what could it do that an alternator cant already do probably more

efficiantly? I may have the wrong end opf the stick, but just throwing it out there.

reply to post by ziplock9000

This link is just a quick example of something GM came up with that uses radiant waste heat around the exhaust pipe rather than internally so as to avoid back pressure. There are also similar setups using heat exchangers that wrap around the tailpipe to heat water and use for similar processes.

goldsea.com...

This link is just a quick example of something GM came up with that uses radiant waste heat around the exhaust pipe rather than internally so as to avoid back pressure. There are also similar setups using heat exchangers that wrap around the tailpipe to heat water and use for similar processes.

goldsea.com...

reply to post by ziplock9000

I actually know of 2 devices designed to harvest heat from exhaust pipes. One is a device GM is working on using nitinol wire that is fairly similar to this device.

www.gminsidenews.com...GM using Nitinol device to harvest exhaust heat

Teg power exhaust heat recovery device

Now there are a couple things to keep in mind here.

1. Nitinol only requires a temperature in the 70-90 celsius range to initiate it's phase change and change shape.

2. Because of this we could do something like jump the Exhaust pipe diameter in one section from 3 inches to 6 inches and still have enough waste heat to run the device. This alone would let you avoid backpressure issues.

3. In theory this would be better than an alternator because once the car is operating at temperature sufficient to make the nitinol phase change you'd be able to clutch your alternator and regain the horsepower lost to it. Alternators do not run for free it takes a measurable amount of the engine's work to turn them. Whereas anything coming out of the tailpipe is basically free energy that was not going to get used anyway.

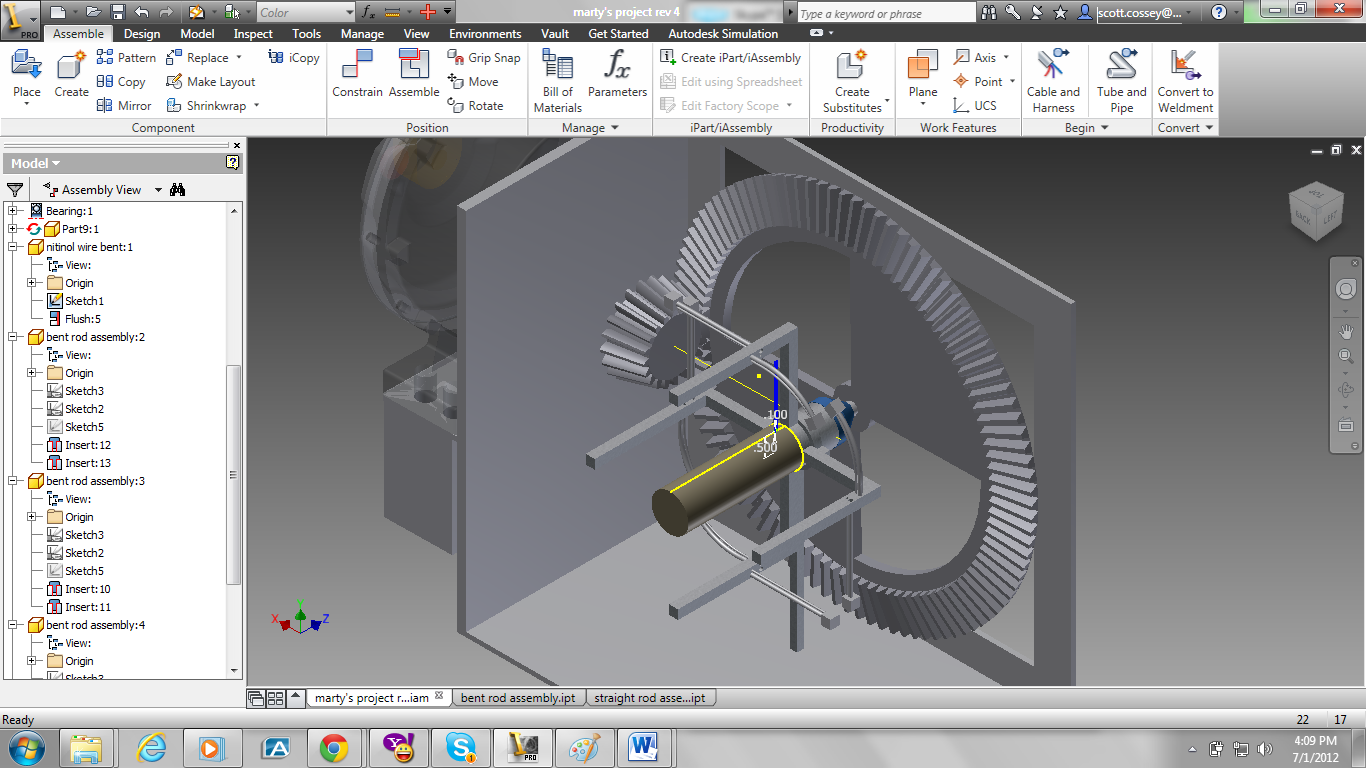

One thing to keep in mind is we are literally in the embryonic stage of this idea. It could still change a massive amount. I think though that by harnessing nitinols strength which are HIGH torque and direct force into a system where the nitinol just oscillates back and forth and we then convert that to rotary motion using a geared assembly gives us the best of both worlds.

Another thing to keep in mind is we're just a trio of guys that want to do something good for the world. Because of this we're going to dedicate our time and money to see if we have a viable idea here. That can hardly be a bad thing.

Overall I have not taken your replies to be antagonistic in the slightest. You have valid questions that help us refine our idea more the more we answer them.

I actually know of 2 devices designed to harvest heat from exhaust pipes. One is a device GM is working on using nitinol wire that is fairly similar to this device.

www.gminsidenews.com...GM using Nitinol device to harvest exhaust heat

Teg power exhaust heat recovery device

Now there are a couple things to keep in mind here.

1. Nitinol only requires a temperature in the 70-90 celsius range to initiate it's phase change and change shape.

2. Because of this we could do something like jump the Exhaust pipe diameter in one section from 3 inches to 6 inches and still have enough waste heat to run the device. This alone would let you avoid backpressure issues.

3. In theory this would be better than an alternator because once the car is operating at temperature sufficient to make the nitinol phase change you'd be able to clutch your alternator and regain the horsepower lost to it. Alternators do not run for free it takes a measurable amount of the engine's work to turn them. Whereas anything coming out of the tailpipe is basically free energy that was not going to get used anyway.

One thing to keep in mind is we are literally in the embryonic stage of this idea. It could still change a massive amount. I think though that by harnessing nitinols strength which are HIGH torque and direct force into a system where the nitinol just oscillates back and forth and we then convert that to rotary motion using a geared assembly gives us the best of both worlds.

Another thing to keep in mind is we're just a trio of guys that want to do something good for the world. Because of this we're going to dedicate our time and money to see if we have a viable idea here. That can hardly be a bad thing.

Overall I have not taken your replies to be antagonistic in the slightest. You have valid questions that help us refine our idea more the more we answer them.

This is about utilizing waste heat.

Originally posted by Idonthaveabeard

If you were thinking of attaching this to some kind of engine, realistically what could it do that an alternator cant already do probably more efficiantly? I may have the wrong end opf the stick, but just throwing it out there.

Mister Ziplock also forgot in his ultimate knowledge (because he knows it can't be done, right?) that one could easily use an extruded aluminum tube for part of the exhaust system, with heat collecting fins formed in one piece with the shell of the pipe (think * in reverse), and the whole lot simply an inch or two greater in diameter than the pipe feeding it. Increased heat transfer, No increase in backpressure, voila!

Geez, it saddens me to think about the education system nowadays. Innovation totally discouraged Ability to regurgitate "facts" passes for understanding

I bet you don't even know who Nikola Tesla was! (that's not directed to idonthaveabeard)

edit on 1-7-2012 by seamus because: fixed

spelling

I guess its just about finding a way to transfer heat from the exhaust to the nitinol. IMO there are so many parts of a car that can be used for

increased efficiency, for example why has no manufacturer ever put a bunch of magents and coil of wires somewhere on the wheel hub of all wheels,

plus there is very high pressure steam that can surely be used.

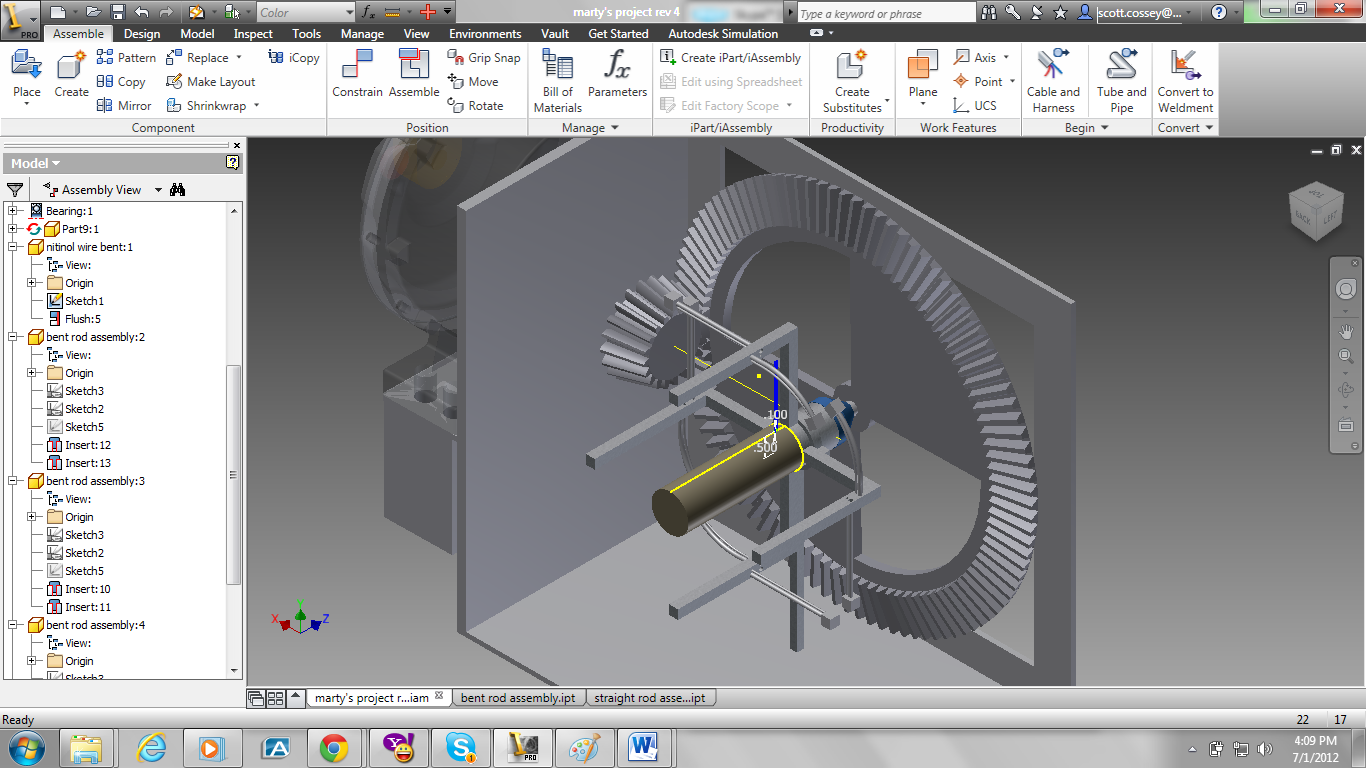

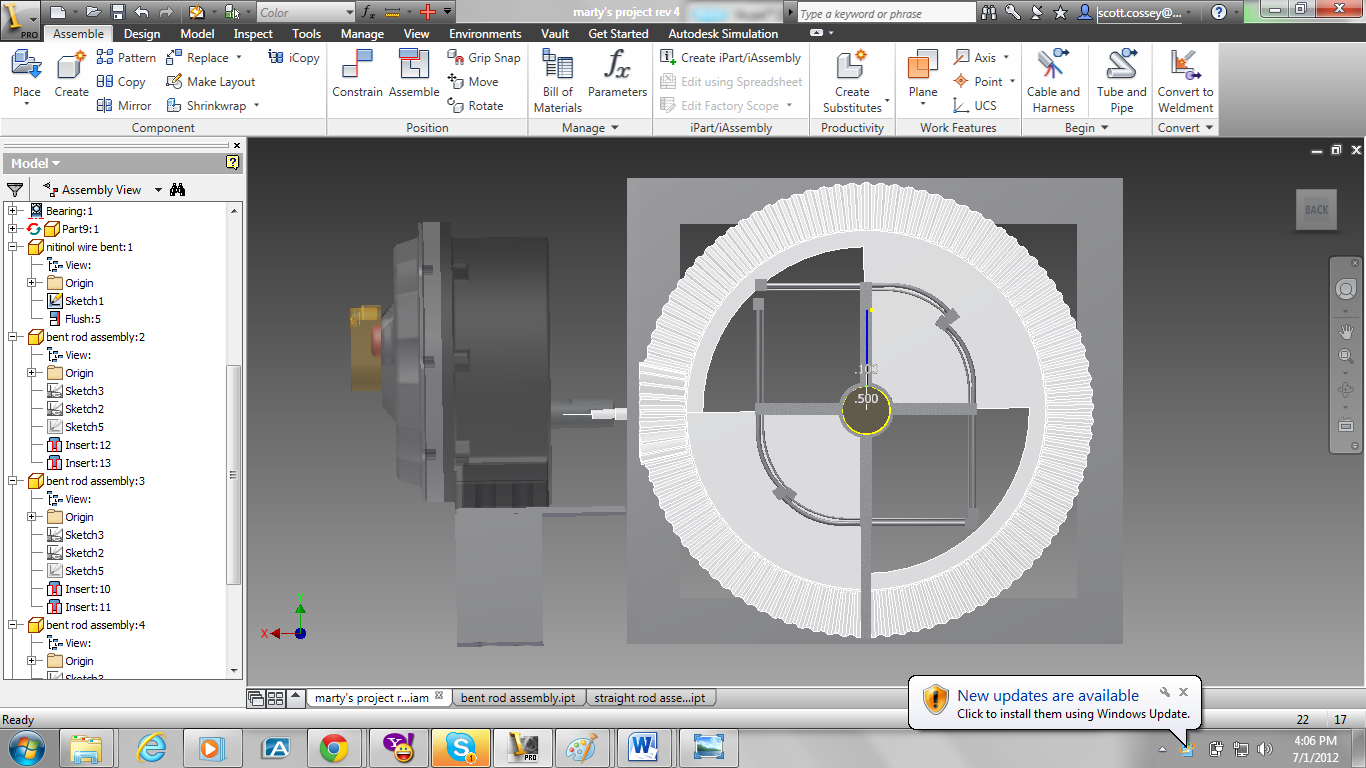

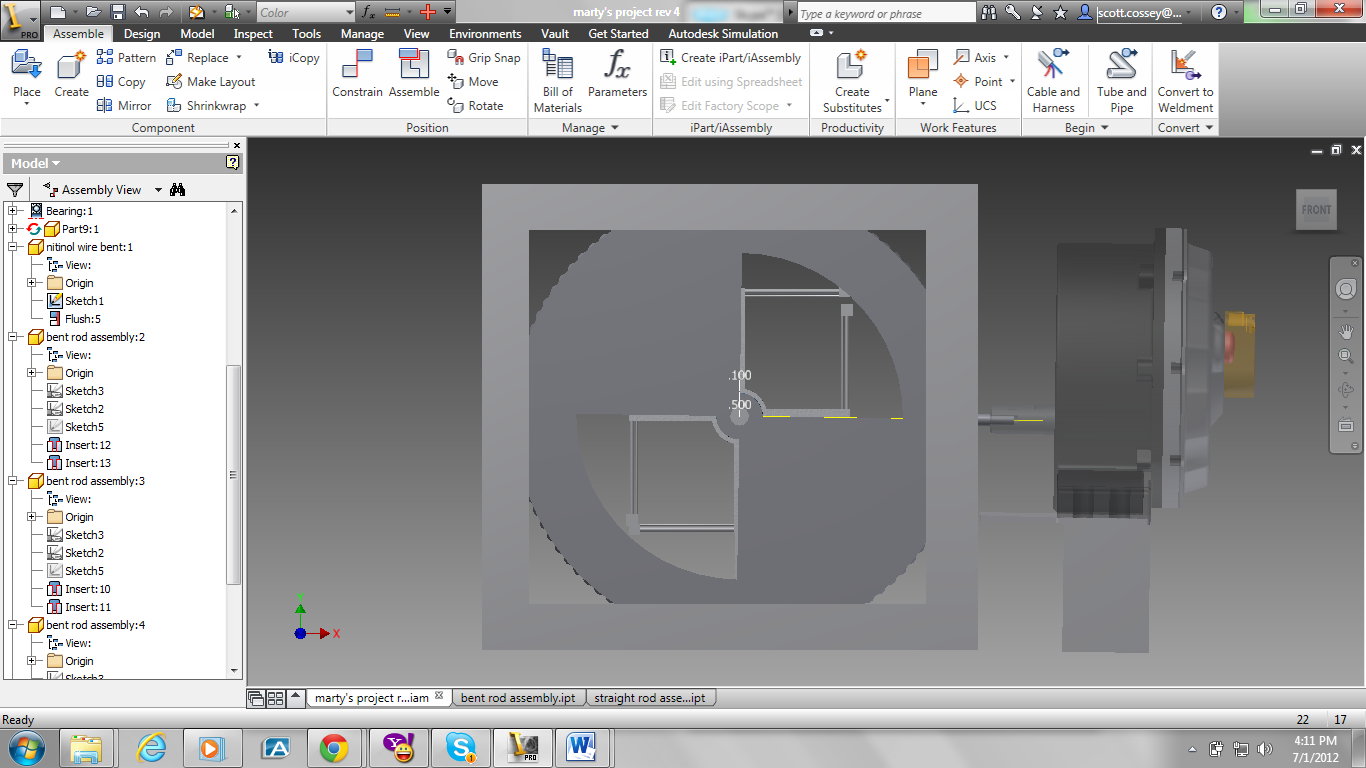

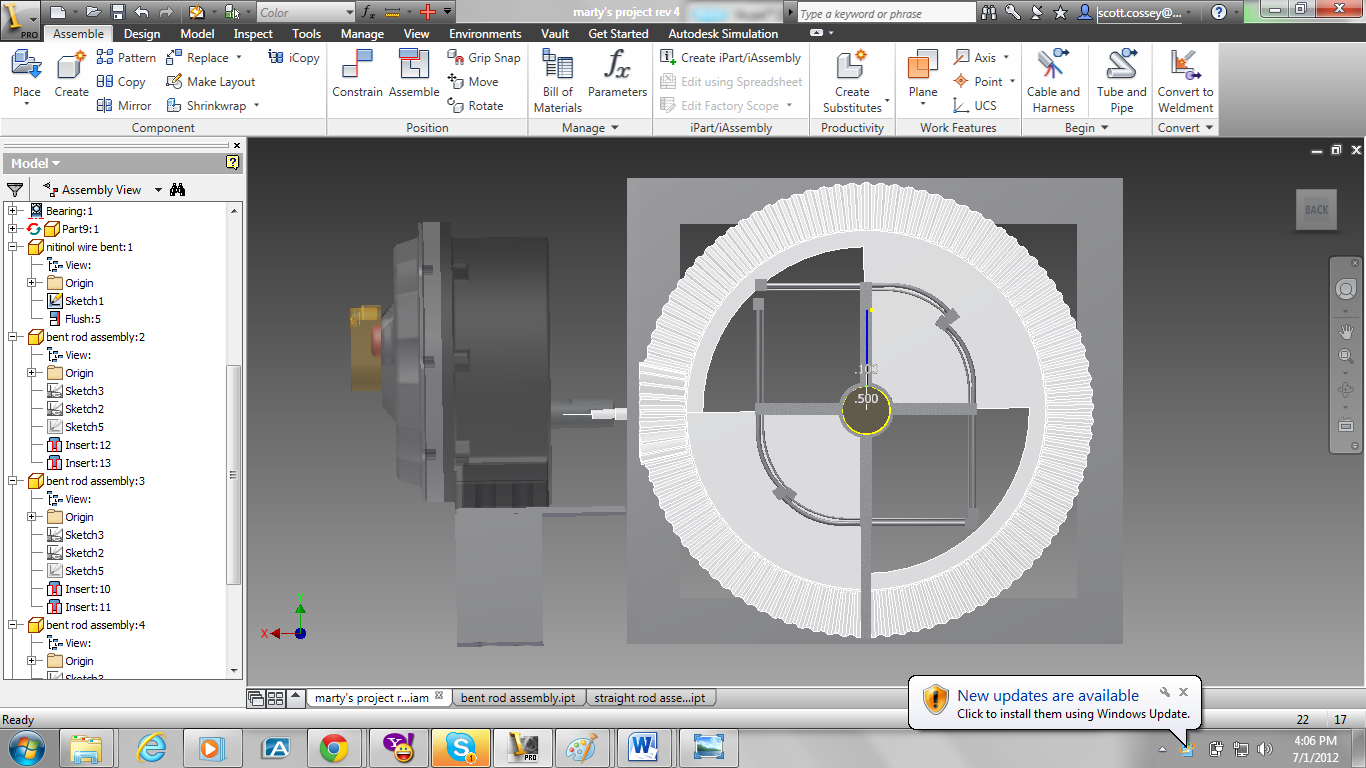

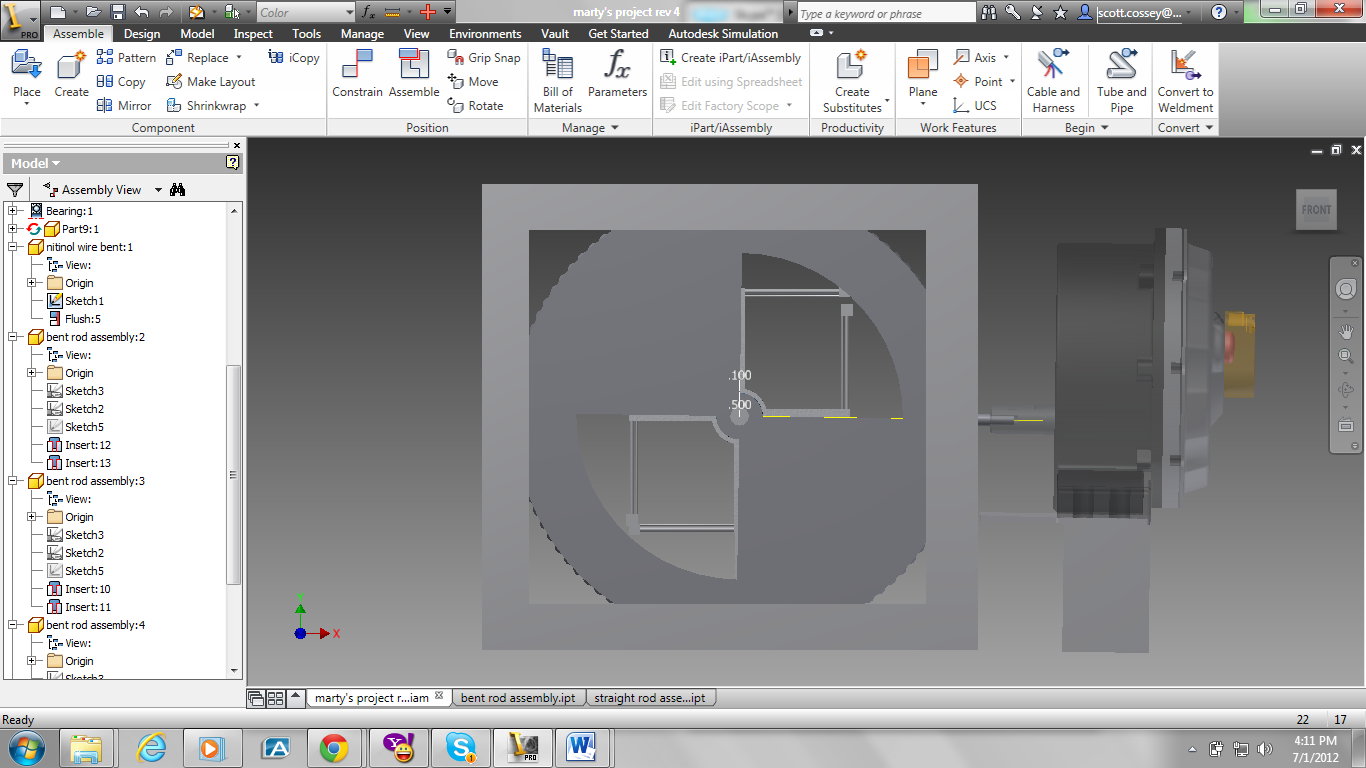

So I've cleaned up the design a little bit and redone some of the 3d modeling No overall changes in basic operation but here are the new pictures.

Now to address the various points being made by various posters.

1. The reason no one puts magnets and coils in wheel hubs is that would create a braking effect. Your engine would have to work harder to power the car. Now regenerative braking is another thing altogether. Personally I think if ford had released it's hydraulic hybrid F-150's that got a 400% gas mileage increase over the original versions and only would have cost an extra 500 dollars to install we'd be much further ahead of the game. But since the Big boys have basically proven that they REFUSE to give us anything that's markedly improved we've gotta do it ourselves.

That's what this project is about. It's not a one shot one kill solution to your energy needs but it could have a place in your toolbox. Imagine running one or even an array of these off of the waste heat your heater produces in the winter and the heat your AC produces in the summer. It of course wouldn't power the AC but it could reduce your bills and with power prices jumping by 8 times in 2015 that's a major deal for most of us!

Now to address the various points being made by various posters.

1. The reason no one puts magnets and coils in wheel hubs is that would create a braking effect. Your engine would have to work harder to power the car. Now regenerative braking is another thing altogether. Personally I think if ford had released it's hydraulic hybrid F-150's that got a 400% gas mileage increase over the original versions and only would have cost an extra 500 dollars to install we'd be much further ahead of the game. But since the Big boys have basically proven that they REFUSE to give us anything that's markedly improved we've gotta do it ourselves.

That's what this project is about. It's not a one shot one kill solution to your energy needs but it could have a place in your toolbox. Imagine running one or even an array of these off of the waste heat your heater produces in the winter and the heat your AC produces in the summer. It of course wouldn't power the AC but it could reduce your bills and with power prices jumping by 8 times in 2015 that's a major deal for most of us!

Ok, so it's destined for heat recovery. Sorry my earlier comments on energy in/out were not warranted.

But....

I think a big challenge is going to be how much energy it takes to get these built. Theoretically you would eventually gain that back, but it would take quite some time!

I think the biggest stumbling block is going to be the actually transfer of the heat energy. The atmosphere between the source and this device is where most of that heat waste is going to go. So I'd wager the rods would need to be directly fixed on the heat source, be it engine block/water heater etc.

Kind of like a heatsink on a cpu!

But at least you guys are giving it a go!

But....

I think a big challenge is going to be how much energy it takes to get these built. Theoretically you would eventually gain that back, but it would take quite some time!

I think the biggest stumbling block is going to be the actually transfer of the heat energy. The atmosphere between the source and this device is where most of that heat waste is going to go. So I'd wager the rods would need to be directly fixed on the heat source, be it engine block/water heater etc.

Kind of like a heatsink on a cpu!

But at least you guys are giving it a go!

Hope this isn't too vague.

In the YouTube video 1970 CNN free energy at 2:24 there is a demonstration of Ridgeway Banks using a circular configuration of nitinol loops

As soon he positioned it into a pool of what was called heated and cooled water it began to spin or rotate.

Could this work in collaberation with electrical magnetic force applications and if so how ?

In the YouTube video 1970 CNN free energy at 2:24 there is a demonstration of Ridgeway Banks using a circular configuration of nitinol loops

As soon he positioned it into a pool of what was called heated and cooled water it began to spin or rotate.

Could this work in collaberation with electrical magnetic force applications and if so how ?

reply to post by Qumulys

You make a good point there. Any time you are trying to convert energy there's a break even point. This is one of those things that we will be testing for. It is still much too early in the game for me to comment on this. I think you definitely have a point though.

You make a good point there. Any time you are trying to convert energy there's a break even point. This is one of those things that we will be testing for. It is still much too early in the game for me to comment on this. I think you definitely have a point though.

reply to post by Cyruay

Nitinol can and will react to electricity through heating (it resistivelly heats) there are any number of small actuators that use nitinol in this manner.

IF you wanted something to react to raw magnetism you'd need to use the material terfenol-D which reacts to magnetic fields.

Nitinol can and will react to electricity through heating (it resistivelly heats) there are any number of small actuators that use nitinol in this manner.

IF you wanted something to react to raw magnetism you'd need to use the material terfenol-D which reacts to magnetic fields.

Interesting thread. I hadn't heard of nitinol before but I have heard of a device called a radiometer

radiometer

It also uses thermodynamics for motion

the way it works are the vanes are colored black and white. The black heats (with ordinary light, no heat) up while the white doesn't.

So I also (as mentioned above) was thinking about a dynamo and pulling a magnet through a coil of wire that generates electricity and powering led flashlights. Too low a yield for anything useful other than led's though. But, the interesting thing about led's is that wired one way they emit light, wired the opposite they detect light.

I don't know if you follow my train of thought and without going into much more detail, color plays an important part in heating (and light - white will illuminate more than black)

I am going to consider this a bit more since it has a few variables that can be adjusted in either of two directions, and I have only put a few minutes worth of thought into it so far

radiometer

It also uses thermodynamics for motion

the way it works are the vanes are colored black and white. The black heats (with ordinary light, no heat) up while the white doesn't.

So I also (as mentioned above) was thinking about a dynamo and pulling a magnet through a coil of wire that generates electricity and powering led flashlights. Too low a yield for anything useful other than led's though. But, the interesting thing about led's is that wired one way they emit light, wired the opposite they detect light.

I don't know if you follow my train of thought and without going into much more detail, color plays an important part in heating (and light - white will illuminate more than black)

I am going to consider this a bit more since it has a few variables that can be adjusted in either of two directions, and I have only put a few minutes worth of thought into it so far

I considered a similar setup but it's just too low powered for our intended purposes. not to mention something like that is better suited for wind

power like the windbelt which uses oscillating magnets in a coil to generate power.

reply to post by roguetechie

Thanks for taking the time to reply. I'll take a look at those links later.

Thanks for taking the time to reply. I'll take a look at those links later.

reply to post by seamus

I never said it can't be done, I'm simply asking questions and offering information. This was highlighted when I said:

"(Honest question, I'm not being an ass)"

Your personal insults and negative comments are not helping with this discussion at all.

Back on topic with another question:

Your aluminium tube with internal fins idea. Do you expect the load on the engine to increase or stay the same when this tube is added to the exhaust?

I never said it can't be done, I'm simply asking questions and offering information. This was highlighted when I said:

"(Honest question, I'm not being an ass)"

Your personal insults and negative comments are not helping with this discussion at all.

Back on topic with another question:

Your aluminium tube with internal fins idea. Do you expect the load on the engine to increase or stay the same when this tube is added to the exhaust?

reply to post by ziplock9000

The inner fins will increase exhaust back pressure, reduce engine efficiency. On the other side cooling exhaust gas will lower back pressure(used in marine engines). Thus it might be done without adverse effects to engine efficiency I guess.

The inner fins will increase exhaust back pressure, reduce engine efficiency. On the other side cooling exhaust gas will lower back pressure(used in marine engines). Thus it might be done without adverse effects to engine efficiency I guess.

reply to post by Im a Marty

Hi,

Just a question;

Supposing the Nitinol rods/wires are conductive, could this methodically recharge/utilize the battery/servo? I don't suppose DC current is all that efficient...?

Hi,

Just a question;

Supposing the Nitinol rods/wires are conductive, could this methodically recharge/utilize the battery/servo? I don't suppose DC current is all that efficient...?

reply to post by ziplock9000

If we do it right I expect a negligeble spike in back pressure if any at all for the simple fact that if we do an exhaust recovery system I intend on making the basic tube diameter large enough that the exhaust can flow freely through that section. Honestly we still have to do a basic function test of the device and see how she handles in the real world first though.

Don't get me wrong I understand what you mean by increasing the exhaust back pressure, but there are relatively simple ways to minimize any spikes while maximizing gains in energy. It will be our job to find and exploit those ways once we get to that point in the project.

If we do it right I expect a negligeble spike in back pressure if any at all for the simple fact that if we do an exhaust recovery system I intend on making the basic tube diameter large enough that the exhaust can flow freely through that section. Honestly we still have to do a basic function test of the device and see how she handles in the real world first though.

Don't get me wrong I understand what you mean by increasing the exhaust back pressure, but there are relatively simple ways to minimize any spikes while maximizing gains in energy. It will be our job to find and exploit those ways once we get to that point in the project.

after sleeping on it I think I have a viable concept that can utilize enough magnetic force to be a viable generator.

In one video the "wheel" was immersed in hot and cold water which made it spin. If that wheel were to have magnets all attached by nitinol coils that kept pulling them kind of like an inchworm type motion then many magnets could be pushed/pulled through field coils and it is the point between north / south where the greatest current is drawn.

Take this a step further, if the magnets themselves were immersed and the wheel started to spin, agitated water creates its own magnetic field which would in itself be an additional reaction

In the ATS model the motion is vertical rebounding but it could also be horizontal and just by its rebounding action alone a current could be drawn from a coil if the motion were fast enough and apparently reaction time is almost instant so it does seem feasible.

If the nitinol were laid out in an offset pattern you would also utilize more motive force in the same system. What I am trying to describe is while one wire rebounded back into its original shape another could already be part-way heated to rebound while yet another is even further from its starting point and if it were stepped like that then it wouldn't merely be a single reaction but multiple reactions (of varying cycle completion) which would increase speed by the number of reactions occurring.

In the wheel in water model the only rebounding taking place was at a defined point and by a specific wire in its completed state (or did I see three of the wires but in smaller diameter cycles - can't remember the whole vid atm) but the point is, smaller diameters spin faster and perhaps that is where the increased efficiency was noted over time?

In one video the "wheel" was immersed in hot and cold water which made it spin. If that wheel were to have magnets all attached by nitinol coils that kept pulling them kind of like an inchworm type motion then many magnets could be pushed/pulled through field coils and it is the point between north / south where the greatest current is drawn.

Take this a step further, if the magnets themselves were immersed and the wheel started to spin, agitated water creates its own magnetic field which would in itself be an additional reaction

In the ATS model the motion is vertical rebounding but it could also be horizontal and just by its rebounding action alone a current could be drawn from a coil if the motion were fast enough and apparently reaction time is almost instant so it does seem feasible.

If the nitinol were laid out in an offset pattern you would also utilize more motive force in the same system. What I am trying to describe is while one wire rebounded back into its original shape another could already be part-way heated to rebound while yet another is even further from its starting point and if it were stepped like that then it wouldn't merely be a single reaction but multiple reactions (of varying cycle completion) which would increase speed by the number of reactions occurring.

In the wheel in water model the only rebounding taking place was at a defined point and by a specific wire in its completed state (or did I see three of the wires but in smaller diameter cycles - can't remember the whole vid atm) but the point is, smaller diameters spin faster and perhaps that is where the increased efficiency was noted over time?

new topics

-

A Warning to America: 25 Ways the US is Being Destroyed

New World Order: 3 hours ago -

President BIDEN's FBI Raided Donald Trump's Florida Home for OBAMA-NORTH KOREA Documents.

Political Conspiracies: 9 hours ago -

Maestro Benedetto

Literature: 10 hours ago -

Is AI Better Than the Hollywood Elite?

Movies: 10 hours ago

top topics

-

President BIDEN's FBI Raided Donald Trump's Florida Home for OBAMA-NORTH KOREA Documents.

Political Conspiracies: 9 hours ago, 28 flags -

Gaza Terrorists Attack US Humanitarian Pier During Construction

Middle East Issues: 15 hours ago, 8 flags -

Massachusetts Drag Queen Leads Young Kids in Free Palestine Chant

Social Issues and Civil Unrest: 17 hours ago, 7 flags -

Las Vegas UFO Spotting Teen Traumatized by Demon Creature in Backyard

Aliens and UFOs: 14 hours ago, 6 flags -

A Warning to America: 25 Ways the US is Being Destroyed

New World Order: 3 hours ago, 6 flags -

Meadows, Giuliani Among 11 Indicted in Arizona in Latest 2020 Election Subversion Case

Mainstream News: 17 hours ago, 5 flags -

2024 Pigeon Forge Rod Run - On the Strip (Video made for you)

Automotive Discussion: 15 hours ago, 4 flags -

Is AI Better Than the Hollywood Elite?

Movies: 10 hours ago, 3 flags -

The functionality of boldening and italics is clunky and no post char limit warning?

ATS Freshman's Forum: 16 hours ago, 1 flags -

Maestro Benedetto

Literature: 10 hours ago, 1 flags

active topics

-

Alternate Electors vs Fake Electors - What is the Difference.

2024 Elections • 116 • : Threadbarer -

Gaza Terrorists Attack US Humanitarian Pier During Construction

Middle East Issues • 34 • : AllisVibration -

Victoria government has cancelled the commmonwealth games, no money.

Regional Politics • 3 • : nazaretalazareta -

A Warning to America: 25 Ways the US is Being Destroyed

New World Order • 2 • : Disgusted123 -

President BIDEN's FBI Raided Donald Trump's Florida Home for OBAMA-NORTH KOREA Documents.

Political Conspiracies • 19 • : ADVISOR -

When an Angel gets his or her wings

Religion, Faith, And Theology • 22 • : AcrobaticDreams1 -

King Charles 111 Diagnosed with Cancer

Mainstream News • 321 • : FlyersFan -

Is there a hole at the North Pole?

ATS Skunk Works • 41 • : burritocat -

Massachusetts Drag Queen Leads Young Kids in Free Palestine Chant

Social Issues and Civil Unrest • 16 • : FlyersFan -

Weinstein's conviction overturned

Mainstream News • 24 • : burritocat