It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

4

share:

Northrup - Grumman test fired the first stage of their heavy lift rocket at Promontory Utah . The first stage is solid fueled derived from the

Space Shuttle SRB Solid rocket boosters,

The Omega is designed for heavy lift to Geo synchronous orbit and to get into launching of Defense Department payloads - Northrup Grumman is already a significant player in the defense industry

en.wikipedia.org...(rocket)

The test firing of the Omega stage proceeded well until the final seconds when the rocket nozzle disintegrated , hurling debris

Can see the results in this video

www.youtube.com...

Northrup - Grumman is investigating the "anomaly"

Space Shuttle SRB Solid rocket boosters,

The Omega is designed for heavy lift to Geo synchronous orbit and to get into launching of Defense Department payloads - Northrup Grumman is already a significant player in the defense industry

en.wikipedia.org...(rocket)

The test firing of the Omega stage proceeded well until the final seconds when the rocket nozzle disintegrated , hurling debris

Can see the results in this video

www.youtube.com...

Northrup - Grumman is investigating the "anomaly"

originally posted by: firerescue

...Northrup Grumman is already a significant player in the defense industry.

A little more of Northrup Grumman's aerospace bio:

Thiokol (or Morton Thiokol) was the company who developed the space shuttle's solid rocket boosters, the technology that we see here in this video. People might remember Thiokol from the 1986 Challenger disaster caused by the failure of a seal on Thiokol's solid rocket booster.

In 2014, Thiokol (by that time named ATK) bought Orbital Sciences Corporation, who was a player similar to SpaceX in providing NASA with private transportation services for sending supplies to the International Space Station (ISS). Orbital Science's spacecraft that delvers supplies to the ISS is called the Cygnus. The combined company was called ATK Orbital.

Last year (in 2018) Northrup Grumman bought ATK Orbital. Northrup Grumman likely wanted ATK's solid booster technology they developed for the shuttle, hence the acquisition. Considering the acquisition came so soon after ATK bought Orbital Sciences also makes me think Northrup Grumman might have also wanted the Cygnus Spacecraft technology, with Cygnus being a proven pressurized and automated spacecraft that has flown to the ISS.

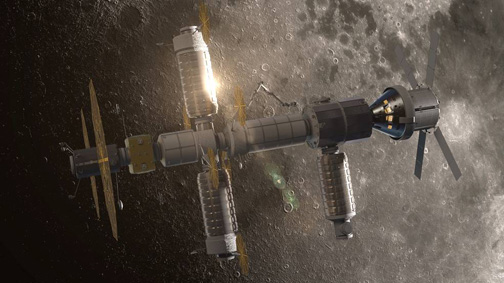

I say this because Northrup Grumman's "Innovation Systems" division recently unveiled concepts for a pressurized module for NASA's Lunar Gateway (NASA's planned Moon-orbiting space station) that is derived from Cygnus technology. The module design would be tested as a potential habitat for the Lunar Gateway.

Northrop Grumman, NASA test Cygnus-derived lunar gateway habitat

NASA Begins Testing Habitation Prototypes

So it seems they want to remain being a major player in the business of space exploration.

By the way, Grumman in the 1960s (before they were Northrup Grumman) was the company who designed and built the Apollo Lunar Module, the craft that landed humans on the moon.

edit on 6/3/2019 by Soylent Green Is People because: (no reason given)

a reply to: firerescue

Do you think it was a defect in the material of the nozzle? It almost looked liked a “burp” in the reaction rate? Maybe the solid fuel wasn’t mixed to the right ratio in a spot?

Do you think it was a defect in the material of the nozzle? It almost looked liked a “burp” in the reaction rate? Maybe the solid fuel wasn’t mixed to the right ratio in a spot?

a reply to: neutronflux

I'm pretty sure the "observation" (their words) was a nozzle failure.

As always, Scott Manley with the low down

I have an acquaintance that works for NG (after their acquisition of Orbital ATK). She worked on the solid boosters, but is very tight lipped about this, so I doubt we will find out if it is related to the new binder of the fuel and oxidizer.

I'm pretty sure the "observation" (their words) was a nozzle failure.

As always, Scott Manley with the low down

I have an acquaintance that works for NG (after their acquisition of Orbital ATK). She worked on the solid boosters, but is very tight lipped about this, so I doubt we will find out if it is related to the new binder of the fuel and oxidizer.

edit on 3-6-2019 by dubiousatworst because: tight lipped

edit on 3-6-2019 by dubiousatworst because: ohh boy.. that is what i

get for not opening the youtube link

a reply to: dubiousatworst

Space Shuttle SRB used Poly Butadiene acrylic nitrile as fuel binder

Northrup went with the more common mix today - Polybutadiene hydroxyl terminated

The fuel - oxidizer mix ( about 70 Ammonium perchlorate, 16 aluminum powder, 12 polybutadiene with remainder

ferric oxide and curing agents) Mix has to baked in giant autoclave to cure it

Wonder if changed material or shape of nozzle to tweak some extra thrust ……

Probably never know complete story

Space Shuttle SRB used Poly Butadiene acrylic nitrile as fuel binder

Northrup went with the more common mix today - Polybutadiene hydroxyl terminated

The fuel - oxidizer mix ( about 70 Ammonium perchlorate, 16 aluminum powder, 12 polybutadiene with remainder

ferric oxide and curing agents) Mix has to baked in giant autoclave to cure it

Wonder if changed material or shape of nozzle to tweak some extra thrust ……

Probably never know complete story

new topics

-

BIDEN Admin Begins Planning For January 2025 Transition to a New President - Today is 4.26.2024.

2024 Elections: 1 hours ago -

Big Storms

Fragile Earth: 2 hours ago -

Where should Trump hold his next rally

2024 Elections: 5 hours ago -

Shocking Number of Voters are Open to Committing Election Fraud

US Political Madness: 6 hours ago -

Gov Kristi Noem Shot and Killed "Less Than Worthless Dog" and a 'Smelly Goat

2024 Elections: 7 hours ago -

Falkville Robot-Man

Aliens and UFOs: 7 hours ago -

James O’Keefe: I have evidence that exposes the CIA, and it’s on camera.

Whistle Blowers and Leaked Documents: 8 hours ago -

Australian PM says the quiet part out loud - "free speech is a threat to democratic dicourse"...?!

New World Order: 8 hours ago -

Ireland VS Globalists

Social Issues and Civil Unrest: 9 hours ago -

Biden "Happy To Debate Trump"

2024 Elections: 9 hours ago

top topics

-

James O’Keefe: I have evidence that exposes the CIA, and it’s on camera.

Whistle Blowers and Leaked Documents: 8 hours ago, 14 flags -

Australian PM says the quiet part out loud - "free speech is a threat to democratic dicourse"...?!

New World Order: 8 hours ago, 13 flags -

Blast from the past: ATS Review Podcast, 2006: With All Three Amigos

Member PODcasts: 12 hours ago, 13 flags -

Biden "Happy To Debate Trump"

2024 Elections: 9 hours ago, 12 flags -

Mike Pinder The Moody Blues R.I.P.

Music: 12 hours ago, 8 flags -

What is the white pill?

Philosophy and Metaphysics: 11 hours ago, 6 flags -

Shocking Number of Voters are Open to Committing Election Fraud

US Political Madness: 6 hours ago, 6 flags -

RAAF airbase in Roswell, New Mexico is on fire

Aliens and UFOs: 9 hours ago, 5 flags -

Ireland VS Globalists

Social Issues and Civil Unrest: 9 hours ago, 5 flags -

Where should Trump hold his next rally

2024 Elections: 5 hours ago, 5 flags

4