It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

share:

a reply to: Biigs

You would think that searching "supercritical CO2" and "safety concerns" would bring up a bunch of hits.

What I have found out. This research has been going on for a while (2010 - 2011) is when it started to pick up... steam (groan, low hanging fruit, sorry). Toshiba tested the turbine last year and it took them a couple years to build. Seems that most interest is in the heat exchange since that has moving parts and fluids--lots of stress.

Since, as noted, this is HOT, they had to create new ceramic alloys to deal with the heat. And corrosion. Likewise, the turbine parts themselves had to be retooled for the higher temperature.

But dang it, no specifics addressing over all safety concerns. Anybody know (i.e., Phage)??

You would think that searching "supercritical CO2" and "safety concerns" would bring up a bunch of hits.

What I have found out. This research has been going on for a while (2010 - 2011) is when it started to pick up... steam (groan, low hanging fruit, sorry). Toshiba tested the turbine last year and it took them a couple years to build. Seems that most interest is in the heat exchange since that has moving parts and fluids--lots of stress.

Since, as noted, this is HOT, they had to create new ceramic alloys to deal with the heat. And corrosion. Likewise, the turbine parts themselves had to be retooled for the higher temperature.

But dang it, no specifics addressing over all safety concerns. Anybody know (i.e., Phage)??

As always in life and nature (to coin an economics term)...there is no free lunch. Everything comes at a cost somewhere along the line.

The "recycling" of nuclear fuel, fissle material and the heavier elements produced is an EXTREMELY DANGEROUS and expensive process. You don't just load this stuff into your average wood-chipper like plastic bottles and grind it up, then melt it down and make something else. It's a highly complex process involving other radioactive elements, highly toxic chemicals and mechanical processes. Not something you can do in your garage (although I'm sure some have tried).

The "recycling" of nuclear fuel, fissle material and the heavier elements produced is an EXTREMELY DANGEROUS and expensive process. You don't just load this stuff into your average wood-chipper like plastic bottles and grind it up, then melt it down and make something else. It's a highly complex process involving other radioactive elements, highly toxic chemicals and mechanical processes. Not something you can do in your garage (although I'm sure some have tried).

edit on 12/20/2016 by Flyingclaydisk because: (no reason given)

a reply to: Flyingclaydisk

Weapons grade plutonium is not something you have just laying around. In Russia, they refine with other material off-site making it less dangerous (or an attractive a target). Then they add it to the fast breeder reactor.

Just read a blurb that says power plants account for about a third of co2 emissions in the US. So I think the plants will be fine. The OP is more of a carbon neutral attempt.

Thanks for the refinery info!

Weapons grade plutonium is not something you have just laying around. In Russia, they refine with other material off-site making it less dangerous (or an attractive a target). Then they add it to the fast breeder reactor.

Just read a blurb that says power plants account for about a third of co2 emissions in the US. So I think the plants will be fine. The OP is more of a carbon neutral attempt.

Thanks for the refinery info!

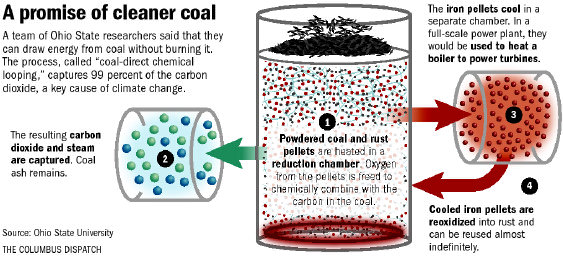

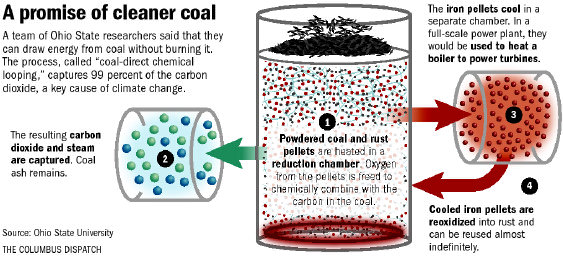

And another, in Ohio:

With coal the most abundant of fossil fuels on our planet the search for clean coal power continues. A new 25-Kilowatt facility at Ohio State University reported the results of a week-long test process that if scaled could dramatically reduce pollutants such as nitrogen oxides and CO2 from coal-fired power plants. The next step involves ramping up to a 1 Megawatt facility.

Today’s power plants using coal as the primary fuel combine air and a coal powder to create the energy to drive steam turbines. The process pollutes. Scrubbers capture the particulate matter in the outflow gases but do not reduce the CO2 and nitrogen oxide enough to impact greenhouse gas emissions. The pilot plant developed by Ohio State, however, uses a process called chemical looping which doesn’t expose the coal to air. Instead coal interacts with iron oxide producing CO2, iron and ferrous oxide in an artificial form called wustite www.21stcentech.com...

originally posted by: TEOTWAWKIAIFF

a reply to: Nickn3

I never thought about it. Probably the same source that hospitals get there? IDK how that is produced either.

One more thing to keep an eye out for.

Oxygen comes from air. Usually, there is an oxygen plant on-site or nearby, which is contracted to provide oxygen and is run by a company that sells gases, such as Air Liquide, Air Products, Praxair, etc. This is a cryogenic process which produces all the other gases in air, also; N2, Ar, CO2, etc. which are then sold.

originally posted by: lordcomac

When the turbine fails, it's an explosion of superheated compressed.... liquid...? carbon.

Still better than anything we've got going, short of hydro.

Hydro is clean, but has a surprisingly high deathprint. Large dam's are pretty catastrophic when they fail.

SO....they use natural Gas to heat the CO2? to great temperatures, to create CO2 "Steam", to spin a turbine????? How much energy would this need to

work?

Modern technology, to use ancient technology......make steam?? Just like so called Hi tech nuclear Power plants, are just a Giant kettle.

In my region, we have funny things called "Gas Turbine" power stations, where a jet turbine is bolted directly to a generator, is powered by clean burning Natural Gas, and instantly creates electricity via direct linkage to the generator..... Eliminating the great big steam kettle idea.....Much more efficient.

And if they wanted to, they could run the exhaust (cooled) emissions, the CO2, thru to giant glass houses full of trees and plants, that would then use the CO2 and produce oxygen, which would be released back to the atmosphere. Almost a zero pollution process. Well....is works in my head anyway.

ALso, why have companies developed mobile transportable gas turbine power plants that can be located in rubbish tips and dumps, and extract the methane to run the power plant, that would create energy for suburbs in the vicinity?

But I know nothing.

Modern technology, to use ancient technology......make steam?? Just like so called Hi tech nuclear Power plants, are just a Giant kettle.

In my region, we have funny things called "Gas Turbine" power stations, where a jet turbine is bolted directly to a generator, is powered by clean burning Natural Gas, and instantly creates electricity via direct linkage to the generator..... Eliminating the great big steam kettle idea.....Much more efficient.

And if they wanted to, they could run the exhaust (cooled) emissions, the CO2, thru to giant glass houses full of trees and plants, that would then use the CO2 and produce oxygen, which would be released back to the atmosphere. Almost a zero pollution process. Well....is works in my head anyway.

ALso, why have companies developed mobile transportable gas turbine power plants that can be located in rubbish tips and dumps, and extract the methane to run the power plant, that would create energy for suburbs in the vicinity?

But I know nothing.

a reply to: TEOTWAWKIAIFF

To little to late through considering the damage we have already done to both our atmosphere and water table. Plus somehow i can see this new technology somewhat increasing our electrical bill under the guise of clean energy costing more to produce.

To little to late through considering the damage we have already done to both our atmosphere and water table. Plus somehow i can see this new technology somewhat increasing our electrical bill under the guise of clean energy costing more to produce.

Just to put this in perspective. This has been worked on for 20+ years and comes and goes. CO2 sequestration has been technically feasible for a long

time. This is what will happen when we no longer need tertiary oil recovery and the value of CO2 goes from a positive value to a negative value. This

means we have to pay to get rid of it. It will go into deep brine aquifers; salt water in sand far below the water table, say 8,000 feet down. The

problems are twofold; costs and legal. The legal problems can be solved with....a law [what else?] exempting the injection from RCRA laws, which

mainly apply to wastewater disposal. Costs are another matter.

If you want an idea of costs, take your electric bill and multiply it by 2 or 3.

If you want an idea of costs, take your electric bill and multiply it by 2 or 3.

There are a couple moving part here. First is supercritical CO2 creation to turn a new, smaller, cheap turbine. Second is the closed-loop aspect where

gas is burned with oxygen to create the CO2 for the first part which keeps it from the atmosphere (where it does it's nasty "global warming"

dance).

Both are part of the demo plant from OP. S-CO2 seems like a no brainer move along with the new turbines.

Hey, even Scientific America gets confused...

Scientific America: Can Carbon Dioxide Replace Steam to Generate Power?

They have taken the turbine with steam as far as it can go and have reached a point of diminishing returns. In an effort to be more efficient the turbine has been updated to turn using S-CO2. Smaller, fewer complexes, more efficient, and less time to reach operating temperature means real savings in money. In the nasty real world it comes down to money. If one guy upgrades the other guy has to follow to stay competitive. Survival of the fittest and all that.

a reply to: gort51

Almost got it. It is called a “closed-loop”. They combust natural gas with oxygen, take that CO2, then compress it, add more heat, use that to turn a new, smaller, cheaper, turbine.

a reply to: andy06shake

No need to raise prices and increase your electricity bill. Heck, keep charging the same rate until you make your money back then everybody’s price falls. I am sure there is some actuary table method or tech tax like they have for 911 tax on your phone bill to deal with upgrades over time.

Both are part of the demo plant from OP. S-CO2 seems like a no brainer move along with the new turbines.

Hey, even Scientific America gets confused...

Much has changed in the modern electric power plant since Thomas Edison's era, but the parts that actually turn heat into electrons haven't changed since his eureka moments. [uh, that was Faraday not Edison. Later it was Tesla not Edison]

Whether burning coal, concentrating sunlight or splitting atoms, most thermal power plants use the energy for the same thing: heating water into steam to drive a turbine. Steam-based generation produces 80 percent of the world's electricity.

After more than a century of incremental improvements in the steam cycle, engineers have plucked most of the low-hanging fruit and are chasing diminishing returns, spending millions of dollars for every percentage point of efficiency improvement. These upgrades propagate to other steps in electricity production, allowing power plants to extract more work for a given unit of fuel.

In a fossil fuel-fired generator, this means less carbon dioxide emissions for the same unit of electricity produced. For a solar thermal plant, this results in higher capacity at lower operating costs.

Now engineers are looking into replacing steam with supercritical carbon dioxide, a technique that could unlock up to 50 percent greater thermal efficiency using a smaller, cheaper turbine.

Scientific America: Can Carbon Dioxide Replace Steam to Generate Power?

They have taken the turbine with steam as far as it can go and have reached a point of diminishing returns. In an effort to be more efficient the turbine has been updated to turn using S-CO2. Smaller, fewer complexes, more efficient, and less time to reach operating temperature means real savings in money. In the nasty real world it comes down to money. If one guy upgrades the other guy has to follow to stay competitive. Survival of the fittest and all that.

a reply to: gort51

Almost got it. It is called a “closed-loop”. They combust natural gas with oxygen, take that CO2, then compress it, add more heat, use that to turn a new, smaller, cheaper, turbine.

a reply to: andy06shake

No need to raise prices and increase your electricity bill. Heck, keep charging the same rate until you make your money back then everybody’s price falls. I am sure there is some actuary table method or tech tax like they have for 911 tax on your phone bill to deal with upgrades over time.

Here is some more on closed-loop systems.

Wikipedia: Supercritical carbon dioxide.

This is an advantage of upgrading to supercritical CO2 and the turbine. Any heat source can be used including nuclear reactors, the ARC/SPARC molten salt fusion reactor on the drawing boards, solar concentrators, even current coal and gas electric power plants. The key is the energy "per unit fuel". Paired up with a thorium reactor would be a good one.

Wikipedia also says S-CO2 is already being used... to decaffeinate coffee because it does not oxidize the beans.

There are also industrial uses. One I find intriguing is making aerogel. Make some graphene and carbon nanotubes from CO2 then use a little S-CO2 to create graphene aerogel.

a reply to: pteridine Thanks for that info! I never thought much about it when the liquid oxygen tanker showed up at the hospital to deliver a tank full.

The unique properties of sCO2 present advantages for closed-loop power generation and can be applied to various power generation applications. Power generation systems that use traditional steam Brayton and Rankine cycles can be upgraded to sCO2 to increase efficiency and power output.

It presents interesting properties that promise substantial improvements in system efficiency. Due to its high fluid density, sCO2 enables extremely compact and highly efficient turbomachinery. It can use simpler, single casing body designs while steam turbines require multiple turbine stages and associated casings, as well as additional inlet and outlet piping. The high density allows for highly compact, microchannel-based heat exchanger technology.

In 2016, General Electric announced an sCO2-based turbine that operated at 50% efficiency. In it the CO2 is heated to 700 °C. It requires less compression and allows heat transfer. It reaches full power in 2 minutes, whereas steam turbines need at least 30 minutes. The prototype generated 10 MW and is approximately 10% the size of a comparable steam turbine

Wikipedia: Supercritical carbon dioxide.

This is an advantage of upgrading to supercritical CO2 and the turbine. Any heat source can be used including nuclear reactors, the ARC/SPARC molten salt fusion reactor on the drawing boards, solar concentrators, even current coal and gas electric power plants. The key is the energy "per unit fuel". Paired up with a thorium reactor would be a good one.

Wikipedia also says S-CO2 is already being used... to decaffeinate coffee because it does not oxidize the beans.

There are also industrial uses. One I find intriguing is making aerogel. Make some graphene and carbon nanotubes from CO2 then use a little S-CO2 to create graphene aerogel.

a reply to: pteridine Thanks for that info! I never thought much about it when the liquid oxygen tanker showed up at the hospital to deliver a tank full.

a reply to: TEOTWAWKIAIFF

Supercritical CO2 has been used to decaffeinate coffee for a while. Methylene chloride was once used but CO2 has many advantages and is used more and more in industry as an alternative to hydrocarbons, especially in the recovery of sensitive molecules from plant matter. SFC chromatography is also used by all drug development labs and prevents deterioration of compounds during separation.

One newer application is the use of SC CO2 in the marijuana industry. All the low THC dross and chaff is extracted and that is added back to the salable product or sold as the oil so as not to waste any of the plant.

Supercritical CO2 has been used to decaffeinate coffee for a while. Methylene chloride was once used but CO2 has many advantages and is used more and more in industry as an alternative to hydrocarbons, especially in the recovery of sensitive molecules from plant matter. SFC chromatography is also used by all drug development labs and prevents deterioration of compounds during separation.

One newer application is the use of SC CO2 in the marijuana industry. All the low THC dross and chaff is extracted and that is added back to the salable product or sold as the oil so as not to waste any of the plant.

a reply to: pteridine

Unless the DEA gets to classify extracts as a schedule 1 drug... again. (sarcasm)

Thanks, I did not know that! That actually makes sense... hash and extracts to maximize crop yield. I think you can also do a cold extract too but would have to ask my buddy with the green thumb to explain it to me1 lol

They also are thinking of using SCO2 for dry cleaning. The Wikipedia citation has a couple other uses.

SCO2, the best way to go green!

Unless the DEA gets to classify extracts as a schedule 1 drug... again. (sarcasm)

Thanks, I did not know that! That actually makes sense... hash and extracts to maximize crop yield. I think you can also do a cold extract too but would have to ask my buddy with the green thumb to explain it to me1 lol

They also are thinking of using SCO2 for dry cleaning. The Wikipedia citation has a couple other uses.

SCO2, the best way to go green!

originally posted by: TEOTWAWKIAIFF

a reply to: pteridine

Unless the DEA gets to classify extracts as a schedule 1 drug... again. (sarcasm)

Thanks, I did not know that! That actually makes sense... hash and extracts to maximize crop yield. I think you can also do a cold extract too but would have to ask my buddy with the green thumb to explain it to me1 lol

They also are thinking of using SCO2 for dry cleaning. The Wikipedia citation has a couple other uses.

SCO2, the best way to go green!

There are many ways to extract plants but if you have the money, SC CO2 is the best way, by far. Rumor has it that growers paid cash for four SC CO2 units from a Pittsburgh company at $250+k/unit. This use of cash is forced on them by the Federal government as banks can't do business with them. They also pay electric bills [$30k/month is not unusual] for the grow lights in cash. The IRS is trapped between wanting to follow the money and the Federal laws that force a cash economy.

Interestingly, the power demand for Colorado increased because of the grow lights which may draw 200 watts per square foot.

edit on 12/22/2016

by pteridine because: syntax error correction

Instead of another thread, I think this fits perfectly along the lines of this thread: Supercritical CO2 and zero emissions power generation. There

terms are the same and the ideas are similar just from another source.

StarTribune, Jan 2, 2016 - TerraCOH believes it can tap the potential of geothermal energy.

So these guys started out at the University of Minnesota and have garnered attention from both the DOE and Lawrence Livermore National Laboratory. These ideas should be familiar if you have read the OP and have followed so far. So CO2 is pumped underground where it is warmer (the article says 1 - 3 miles down). The more pressure and heat causes the CO2 to go supercritical. It is stored until needed where it expands back up through a bore hole to turn a turbine and is pumped back underground as a it cools. Basically, the heat of the earth creates a CO2 battery!

There article is worth a read. Anyway, they figured they would start where there are already bore holes drilled (oil fields) instead of finding geothermic sources. After the technology is proven, they would do what the Texas pilot plant is doing and hook up to a gas (or coal) powered plant, but instead of turning a turbine right then, pump it underground until there is enough CO2, then let the process turn a SC turbine.

I hope their plant demonstrates efficient and effective zero emission closed circle power generation! Best of luck this year! I will be keeping tabs on their progress.

TerraCOH’s vision is grand. The fledgling firm would use carbon dioxide emissions — a nemesis to the planet — to power a geothermal energy system, which would in turn produce low-cost, clean electricity.

...

TerraCOH’s technology uses “supercritical” CO2 to efficiently unlock that thermal energy. Supercritical is a chemical state somewhere between a gas and a liquid. It’s dense and has a lower viscosity than water, so it flows easy. Oil companies use compressed CO2 to scour the last bits of petroleum from conventional wells.

...

The good news: TerraCOH believes this year it will fire up a small-scale commercial version [pilot plant] of its power system. “We are ready to build the power plant,” said Jimmy Randolph, TerraCOH’s chief technical officer. “And we’re trying to raise the money to do that,” chimed in Chief Executive John Griffin.

...

TerraCOH’s technology uses “supercritical” CO2 to efficiently unlock that thermal energy. Supercritical is a chemical state somewhere between a gas and a liquid. It’s dense and has a lower viscosity than water, so it flows easy. Oil companies use compressed CO2 to scour the last bits of petroleum from conventional wells.

In TerraCOH’s system, supercritical CO2 heats up as it’s pumped lower into the earth and is stored in porous sedimentary rock. The hot CO2 can then be drawn back up to the earth’s surface — without costly pumping — where it spins a turbine to create electricity. It’s an energy loop, basically.

...

The company is planning a small power plant [pilot] at a conventional oil well in northwest North Dakota that will produce electricity for that site...

But the long-term goal is to place TerraCOH Plume Geothermal systems near coal-fired or gas-fired power plants, directly capturing CO2 emissions, pumping them into the ground for eventual use in bigger CO2 fired-power plants. These plants would initially generate up to 15 megawatts, but could eventually be up to 300 megawatts.

StarTribune, Jan 2, 2016 - TerraCOH believes it can tap the potential of geothermal energy.

So these guys started out at the University of Minnesota and have garnered attention from both the DOE and Lawrence Livermore National Laboratory. These ideas should be familiar if you have read the OP and have followed so far. So CO2 is pumped underground where it is warmer (the article says 1 - 3 miles down). The more pressure and heat causes the CO2 to go supercritical. It is stored until needed where it expands back up through a bore hole to turn a turbine and is pumped back underground as a it cools. Basically, the heat of the earth creates a CO2 battery!

There article is worth a read. Anyway, they figured they would start where there are already bore holes drilled (oil fields) instead of finding geothermic sources. After the technology is proven, they would do what the Texas pilot plant is doing and hook up to a gas (or coal) powered plant, but instead of turning a turbine right then, pump it underground until there is enough CO2, then let the process turn a SC turbine.

I hope their plant demonstrates efficient and effective zero emission closed circle power generation! Best of luck this year! I will be keeping tabs on their progress.

a reply to: lordcomac

The temperatures and pressures are within engineering norms. Steam turbines routinely operate at 165 bar, 585 C. Do you want to be near one if there is an issue? No, but it doesn't happen often.

To bring co2 into a super critical state, it needs to be stored at no less than 100bar- something like 1500psi.

The temperatures and pressures are within engineering norms. Steam turbines routinely operate at 165 bar, 585 C. Do you want to be near one if there is an issue? No, but it doesn't happen often.

a reply to: andy06shake

Nextbifuture.com, Dec. 2013 - Roadmap to Supercritical CO2 turbines.

That article is from the original announcement in 2013. The new S-CO2 turbines also perform another function: futureproofing. The little quip highlight about "any heat source" is further discussed at the end of that article. The thought is that a molten salt reactor could be used as heat source. That would be two birds with one stone, clean up the nuclear fission cycle, and generate electricity efficiently.

GE wants to use a solar tower and store S-CO2 underground until it is needed to turn the turbine when the sun is not shining.

Still, the new turbines cost money, and probably see some kid of tax, I guess. But size is a factor. Especially for remote locations.

The high density of the fluid makes the power density very high because the turbomachinery is very small. The machine is basically a jet engine running on a hot liquid, though there is no combustion because the heat is added and removed using heat exchangers. A 300 MWe S-CO2 power plant has a turbine diameter of approximately 1 meter and only needs 3 stages of turbomachinery, while a similarly sized [output] steam system has a diameter of around 5 meters and may take 22 to 30 blade rows of turbomachinery.

Supercritical CO2 gas turbine systems promise an increased thermal-to-electric conversion efficiency of 50 percent over conventional gas turbines. The system is also very small and simple, meaning that capital costs should be relatively low. The plant uses standard materials like chrome-based steel alloys, stainless steels, or nickel-based alloys at high temperatures (up to 800 °C). It can also be used with all heat sources, opening up a wide array of previously unavailable markets for power production.

Nextbifuture.com, Dec. 2013 - Roadmap to Supercritical CO2 turbines.

That article is from the original announcement in 2013. The new S-CO2 turbines also perform another function: futureproofing. The little quip highlight about "any heat source" is further discussed at the end of that article. The thought is that a molten salt reactor could be used as heat source. That would be two birds with one stone, clean up the nuclear fission cycle, and generate electricity efficiently.

GE wants to use a solar tower and store S-CO2 underground until it is needed to turn the turbine when the sun is not shining.

Still, the new turbines cost money, and probably see some kid of tax, I guess. But size is a factor. Especially for remote locations.

originally posted by: lordcomac

originally posted by: Biigs

This could definitely be super-critical to the future of the planet and of smaller plants.

Are their any safety concerns vs steam turbines i just wondering.

Super ridiculous pressures, really, are the concern.

To bring co2 into a super critical state, it needs to be stored at no less than 100bar- something like 1500psi.

It turns to a liquid at 800psi, so compressing it further becomes.... increasingly difficult. Although keeping it at a couple hundred degrees (hotter than steam) does help.

The good news is that the danger is local. If the system fails, it's no more violent than a giant propane tank exploding- and it releases nothing but co2. No fire, no methane, no radiation.

most newer steam power plants run at +1500psi steam pressure.

steam power plants are rated at there steam pressure and there are even a few plants running at 4500psi.

if you walk in front of a leak in a 1500psi steam line i will cut you in two like a laser.

no blood no mess.

new topics

-

George Stephanopoulos and ABC agree to pay $15 million to settle Trump defamation suit

Mainstream News: 2 hours ago -

More Bad News for Labour and Rachel Reeves Stole Christmas from Working Families

Regional Politics: 9 hours ago -

Light from Space Might Be Travelling Instantaneously

Space Exploration: 10 hours ago -

The MSM has the United Healthcare assassin all wrong.

General Conspiracies: 11 hours ago -

2025 Bingo Card

The Gray Area: 11 hours ago

top topics

-

The Mystery Drones and Government Lies

Political Conspiracies: 13 hours ago, 14 flags -

George Stephanopoulos and ABC agree to pay $15 million to settle Trump defamation suit

Mainstream News: 2 hours ago, 12 flags -

Light from Space Might Be Travelling Instantaneously

Space Exploration: 10 hours ago, 8 flags -

2025 Bingo Card

The Gray Area: 11 hours ago, 7 flags -

The MSM has the United Healthcare assassin all wrong.

General Conspiracies: 11 hours ago, 7 flags -

More Bad News for Labour and Rachel Reeves Stole Christmas from Working Families

Regional Politics: 9 hours ago, 7 flags

active topics

-

George Stephanopoulos and ABC agree to pay $15 million to settle Trump defamation suit

Mainstream News • 8 • : xuenchen -

Pelosi injured in Luxembourg

Other Current Events • 33 • : WeMustCare -

Drones everywhere in New Jersey

Aliens and UFOs • 132 • : FlatBatt -

Light from Space Might Be Travelling Instantaneously

Space Exploration • 22 • : Freeborn -

The Mystery Drones and Government Lies

Political Conspiracies • 66 • : nugget1 -

They Know

Aliens and UFOs • 85 • : ARM19688 -

Nov 2024 - Former President Barack Hussein Obama Has Lost His Aura.

US Political Madness • 14 • : xuenchen -

2025 Bingo Card

The Gray Area • 15 • : onestonemonkey -

-@TH3WH17ERABB17- -Q- ---TIME TO SHOW THE WORLD--- -Part- --44--

Dissecting Disinformation • 3681 • : Thoughtful3 -

Something better

Dissecting Disinformation • 25 • : Astrocometus