It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

share:

I have cast geopolymers in platinum silicone molds, but i would imagine that if the object is not meant to be lifted, just sitting at ground level, one could use mud and straw, if it is an object high up, then wooden boards. for detailed smaller objects resin is not out of the question. In south america, rubber gives an amazing opportunity to create extremely detailed and polished finishes to objects because the master could be a clay sculpture, then they would just make a rubber mold and a support mold before pouring their material in.

I can probably assume that the AE didn't have platinum silicone moulds.

Melting point of granite is 1215–1260 °C .

Id like to rule out wood as a possibility for these moulds , as , during lockdown , I built myself a Pizza oven in my garden - using the Pompeii design - ( pizzas are off the scale good, my brother in law is Italian, he goes crazy for them) now , using a digital thermometer I have fired my oven to 800 •C to see how hot I could get it. When you place wood inside it at 800•C, the wood instantly sets ablaze. Well, within about 4-5 seconds .

So that leaves Mud and Straw according to your theory. Not sure how much better they would fare at granite melting temperature.

Perhaps you could show us some pictures of Granite that has been melted and then cooled, and how it relates to Granite that hasn’t been melted, visually speaking.

Are you also claiming that AE granite statues (beautiful things that they are) are formed from moulds? What moulds? Wood, or mud or straw?

Thanks

a reply to: XipeTotex

a reply to: bluesfreak

The pizza oven sounds cool.

But i do not think you understand the concept.

Materials like sandstone or granite aggregate can be bound by a geopolymer base.

No heating or melting of any kind is needed to achieve a look that is exactly like natural stone.

You can only tell them apart from natural stone if you have an electron microscope, and if you know what to look for, a geologist sees nothing, and an egyptologist is blind when it comes to these matters.

The scientists that are currently working on these things actually sent sandstone geopolymers for geologists to look at, they told the chemists that they were natural stones. Was kinda funny.

Sometimes i wonder why some people are so against this idea, even when it has science backing it up, they have no problems with pretty advanced alchemy that has been done aeons ago, Mayan blue a nanostructured pigment, all kinds of concretes and advanced ceramics, extremely clever chemistry behind tanning animal hides. Complicated medicinal compounds from plants.

But when it comes to geopolymers that are relatively simple to make- people go- no this is impossible!

I think its because it crashes the Disney mystery ride.

I have a friend who is a basic boring and rational person, he told me that he thinks they somehow singed the pyramid stones in place with some sort of vibration.

I do not know where to even begin with that, possible? maybe... Likely? Not so much.

I mean take you roman concrete for example, and a note that was written in 79 B.C.E, "A single stone mass, impregnable to the waves, and everyday stronger" Now how in hello did they know, that seawater dissolves components from volcanic ash creating hydrothermal minerals like aluminum tobermorite and philipsite, those take centuries to strenghten the final form.

Its actually quite upsetting to me, because people do not give enough credit to our ancestors and how well they used their surroundings and materials available.

We are stupid children making a mess compared to how well they were adapted to this planet.

The pizza oven sounds cool.

But i do not think you understand the concept.

Materials like sandstone or granite aggregate can be bound by a geopolymer base.

No heating or melting of any kind is needed to achieve a look that is exactly like natural stone.

You can only tell them apart from natural stone if you have an electron microscope, and if you know what to look for, a geologist sees nothing, and an egyptologist is blind when it comes to these matters.

The scientists that are currently working on these things actually sent sandstone geopolymers for geologists to look at, they told the chemists that they were natural stones. Was kinda funny.

edit on 15-7-2021 by XipeTotex because: (no reason given)

Sometimes i wonder why some people are so against this idea, even when it has science backing it up, they have no problems with pretty advanced alchemy that has been done aeons ago, Mayan blue a nanostructured pigment, all kinds of concretes and advanced ceramics, extremely clever chemistry behind tanning animal hides. Complicated medicinal compounds from plants.

But when it comes to geopolymers that are relatively simple to make- people go- no this is impossible!

I think its because it crashes the Disney mystery ride.

I have a friend who is a basic boring and rational person, he told me that he thinks they somehow singed the pyramid stones in place with some sort of vibration.

I do not know where to even begin with that, possible? maybe... Likely? Not so much.

edit on 15-7-2021 by XipeTotex because: (no reason

given)

I mean take you roman concrete for example, and a note that was written in 79 B.C.E, "A single stone mass, impregnable to the waves, and everyday stronger" Now how in hello did they know, that seawater dissolves components from volcanic ash creating hydrothermal minerals like aluminum tobermorite and philipsite, those take centuries to strenghten the final form.

Its actually quite upsetting to me, because people do not give enough credit to our ancestors and how well they used their surroundings and materials available.

We are stupid children making a mess compared to how well they were adapted to this planet.

edit on 15-7-2021 by XipeTotex because: (no reason

given)

The sarcophagus looks out of place, like someone placed it there for a tourist attraction.

originally posted by: imitator

The sarcophagus looks out of place, like someone placed it there for a tourist attraction.

Yeah. Gotta be careful about this stuff that's been lying around for a couple thousand years. Lots of opportunity for monkey business. Like the folks who meticulously study the measurements of Stonehenge for some insight into the builders but don't understand that the way it looks now is a hasty and inaccurate modern reconstruction.

originally posted by: Byrd

Perhaps you should do as the Egyptologists do and take a really close look at the sarcophagi (those interior corners are actually rounded where the drill punched down through the stone)

The corners are rounded although the radius is minimal, in the case of this particular sarcophagus it's about the size of the tip of a ballpoint pen (click for fullsize image):

The paper you linked is interesting. Looks like Gorelick and Gwinnett favor the method of drilling using a diamond abrasive combined with olive oil or a modern lubricant. The complete article incl. illustrations is available here:

Ancient Egyptian Stone Drilling (PDF)

The tests were done while drilling at 1000 rpm. Emery or corundum would be runner-ups that would also produce concentric grooves. It also looks like it's not a 100% match, which is why they suggest further research.

That was 1983, do you know whether there has been any follow up to their work?

edit on 18-7-2021 by jeep3r because: formatting

originally posted by: jeep3r

originally posted by: Byrd

Perhaps you should do as the Egyptologists do and take a really close look at the sarcophagi (those interior corners are actually rounded where the drill punched down through the stone)

The corners are rounded although the radius is minimal, in the case of this particular sarcophagus it's about the size of the tip of a ballpoint pen (click for fullsize image):

Thanks for the pictures. They're excellent, although I think the pen one is a bit biased by the angle. If you look closely at the other photo, the corner doesn't appear to be that sharply defined.

The paper you linked is interesting. Looks like Gorelick and Gwinnett favor the method of drilling using a diamond abrasive combined with olive oil or a modern lubricant. The complete article incl. illustrations is available here:

Ancient Egyptian Stone Drilling (PDF)

The tests were done while drilling at 1000 rpm. Emery or corundum would be runner-ups that would also produce concentric grooves. It also looks like it's not a 100% match, which is why they suggest further research.

That was 1983, do you know whether there has been any follow up to their work?

Not that I know of, and the use of emery (which would have been available, though of very variable composition) seemed a logical conclusion... though sand is still not ruled out, as sand is NOT a consistent material and sands from one location are different than sands from another.

We see examples in jewelry where they get a very nice glossy polish on gemstones, so we know they had a finishing product that was better than sand or crushed sand. I have not investigated further, though.

There are some unfinished granite sarcophagi lying around, including this one in the schist quarries . Although the top is rounded you can clearly see how they're working the insides -- your idea of how the work was done and their work methods don't seem to be the same.

Hi Byrd.

The sarcophagus you refer to shows a different method of construction than the Granite object we are discussing, a different method because the schist stone was softer and easier to work -(4-5 on Mohs scale ) this is obvious by the vertical roughing lines inside showing how a carving tool can reach the top to the bottom of the internal sides in one set of hammered strokes.

This would not be possible with granite, with copper ‘chisels’.

It is a beautiful thing though , with a great looking external radius at the top end.

This , however , is another level of execution :

The 90 degree corners , internally and externally look incredibly accurate.

The corner at the front is chamfered ( a technique we use in engineering today for a) aesthetics , but also b) to stop yourself getting hurt by a sharp edge ,c) to protect an edge from being damaged.

Other edges on this piece are not chamfered, implying this was deemed necessary.

You have suggested that a ‘drill’ made these internal corners-(the ballpoint pen tip width) it would have to be a VERY thin drill to execute that operation, from top to bottom of the corner , I’m sure they would have snapped many of them, incidentally, what was proposed drill made from?

How did the AE calibrate their 90 degree angles, and straight edges ? To do so , you need something very accurate to ‘check’ your work against.

Have there been AE ‘straight edge ‘ tools found, for checking work?

Have AE ‘set squares’ been found ,checked and calibrated to see how they stack up against work such as this?

I do find it highly interesting that many people who work in fabrication often marvel at the accuracy of these type of objects, when archaeologists simply say “ yeh, it’s nothing special, easy! Move along!!”

Yet , we often see the work of Denys Stocks sited as ‘proof’ when his work is highly debatable to anyone with the slightest understanding of engineering.

Has anyone ever calculated just how many thousands of tonnes of copper the AE would have needed to achieve said accomplishments all over Egypt , as the loss of copper, sawing , for example , one granite sarcophagus externally (let alone internally) would have run into kilos and kilos per side.

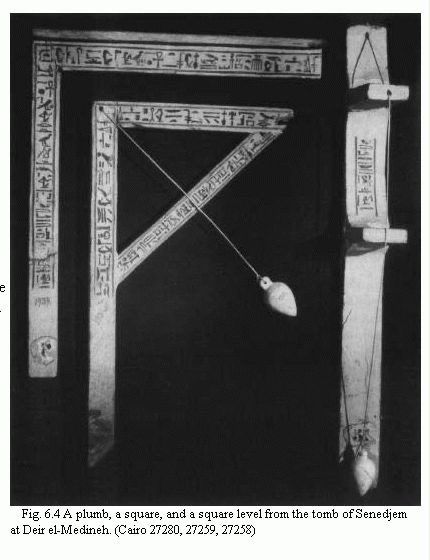

EDIT: had a look for AE ‘squares’ , found this:

I have to say, the set square on the left , just by sight , doesn’t look as accurate as the edges on this sarcophagus discussed.

It could be a carpentry version , in modern times , a carpentry ‘square’ is not as accurate as an engineering square , as the tolerances are not required to be as accurate in carpentry ( no offense meant to any brilliant carpenters/joiners, that’s just how it is), I’d love to see what the calibration tolerances of those AE ‘squares’ are….

a reply to: Byrd

edit on 20-7-2021 by bluesfreak because: (no reason given)

originally posted by: bluesfreak

The sarcophagus you refer to shows a different method of construction than the Granite object we are discussing, a different method because the schist stone was softer and easier to work -(4-5 on Mohs scale ) this is obvious by the vertical roughing lines inside showing how a carving tool can reach the top to the bottom of the internal sides in one set of hammered strokes.

This would not be possible with granite, with copper ‘chisels’.

The idea that you can't use a copper chisel on granite is simply not true, although that's not how they carved granite anyway.

You can use a flint chisel on granite and it will do the job. Copper is more than enough. Besides, their copper was a natural copper-arsenic alloy that was a lot like bronze.

But for large hollows like a sarcophagus or a vessel, they drilled the interior, they didn't do much chiseling. The corners were done by rubbing, not chiseling. Exteriors were sawn then rubbed for the flatness and finish.

Harte

originally posted by: bluesfreak

..

The corner at the front is chamfered ( a technique we use in engineering today for a) aesthetics , but also b) to stop yourself getting hurt by a sharp edge ,c) to protect an edge from being damaged.

Other edges on this piece are not chamfered, implying this was deemed necessary.

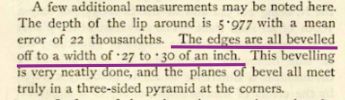

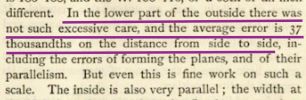

from what Petrie found all edges are bevelled..

but this is interesting, there seem to be some parts not so perfectly done, meaning this could imply handmade.

imho.

edit on 20-7-2021 by anti72 because: (no reason given)

Tube saw was used for the interior. Approximately 11 cm. in diameter.

Page 173:

Denys Stocks: Experiments in Egyptian Archaeology

Harte

Page 173:

Denys Stocks: Experiments in Egyptian Archaeology

Harte

originally posted by: bluesfreak

There are some unfinished granite sarcophagi lying around, including this one in the schist quarries . Although the top is rounded you can clearly see how they're working the insides -- your idea of how the work was done and their work methods don't seem to be the same.

Hi Byrd.

The sarcophagus you refer to shows a different method of construction than the Granite object we are discussing, a different method because the schist stone was softer and easier to work -(4-5 on Mohs scale ) this is obvious by the vertical roughing lines inside showing how a carving tool can reach the top to the bottom of the internal sides in one set of hammered strokes.

This would not be possible with granite, with copper ‘chisels’.

The chisels they had were not pure copper, but hardened copper and alloyed (naturally) with arsenic which produces a kind of low quality bronze. (Egyptian knowledge of metalworking )They also had iron tools, but they were very rare and only in the hands of the master craftsmen.

The corner at the front is chamfered ( a technique we use in engineering today for a) aesthetics , but also b) to stop yourself getting hurt by a sharp edge ,c) to protect an edge from being damaged.

Other edges on this piece are not chamfered, implying this was deemed necessary.

Now consider Option C... from the viewpoint of sliding the lid on (tilt granite slab, slide on.)

You have suggested that a ‘drill’ made these internal corners-(the ballpoint pen tip width) it would have to be a VERY thin drill to execute that operation, from top to bottom of the corner , I’m sure they would have snapped many of them, incidentally, what was proposed drill made from?

I think they would have chiseled it. They could chisel hieroglyphs into granite with great precision, so I don't see any problems with their chiseling a nice corner and leveling it with a sanding block.

We know they had those and they left pictures of themselves using drills on other objects.

How did the AE calibrate their 90 degree angles, and straight edges ?

The answer is there in the picture you supplied. You put up a straight piece of material and hang a string from it with a plumb bob. Instant and accurate 90 degree angle. And before you asked, they apparently used water as a leveling tool, much as we use a level today.

Precise 90 degree angles are a very old technique.

I do find it highly interesting that many people who work in fabrication often marvel at the accuracy of these type of objects, when archaeologists simply say “ yeh, it’s nothing special, easy! Move along!!”

It's the other way around, actually... we say "nothing miraculous but solid evidence of the history of tools and technology. And we're delighted." We don't see ancient aliens, supernatural knowledge given to only one small group of people for a few years and then forgotten. If you look at other nations of that timeframe you'll see similar examples of precise cutting and toolwork. We're talking 12th Dynasty here, so this kind of precision is all over the Middle East (brief overview of Senwoseret II's century)

Some of the non-scholarly pages tend to treat each civilization as though it existed in a vacuum with everyone else crouching in caves and wearing animal skins and hunting fleas.

a reply to: Harte

I've heard people say the metric system coincidentally measures a distance of 10,000 KM's from the equator to the poles.

We probably can't prove that 11 CM's was much more than a coincidental projection.

Edit: to add

Page 190 is actually 223 which is a little confusing but it claims that maybe they didn't use a shadow?

Sounds like a puzzle from the Amazon new world video game.

I've heard people say the metric system coincidentally measures a distance of 10,000 KM's from the equator to the poles.

We probably can't prove that 11 CM's was much more than a coincidental projection.

Edit: to add

Page 190 is actually 223 which is a little confusing but it claims that maybe they didn't use a shadow?

A string was then tautly stretched between two rods, each rod standing upright in its levelled trough. The obelisk’s top surface would be levelled with stone tools, its flatness being tested by using the third matched rod to check the space beneath the string along its whole length. MASTER MASONRY FITTERS189 Figure 7.12 The rods and string ready for testing a surface for flatness

Sounds like a puzzle from the Amazon new world video game.

edit on 21-7-2021 by fromunclexcommunicate because: (no reason given)

originally posted by: fromunclexcommunicate

a reply to: Harte

I've heard people say the metric system coincidentally measures a distance of 10,000 KM's from the equator to the poles.

That's not a coincidence. That's how they determined what a "kilometer" would be. One ten-millionth the distance from pole to equator

Page 190 is actually 223 which is a little confusing but it claims that maybe they didn't use a shadow?

A string was then tautly stretched between two rods, each rod standing upright in its levelled trough. The obelisk’s top surface would be levelled with stone tools, its flatness being tested by using the third matched rod to check the space beneath the string along its whole length. MASTER MASONRY FITTERS189 Figure 7.12 The rods and string ready for testing a surface for flatness

Much easier than using a shadow, really.

originally posted by: Harte

Tube saw was used for the interior. Approximately 11 cm. in diameter.

Page 173:

Denys Stocks: Experiments in Egyptian Archaeology

Harte

thanks for thelink.

when I look at the proposed drilling placement and usage I'm not so sure if that would be the best solution.

talking 'bout the placement here. I´m not a stone cutting technician.

I understand the theoretical drilling pattern to get the main middle hole cut out, makes sense, ok.

But in that there is a problem, IMHO thats not a solution for the most difficult part, the edges.

see, when somebody drilles it that way, the most difficult edge parts had to be carved/ cut whatever later.

you couldnt do that with a round, circular saw because you had no stable room to place it vertically, and the edges are crucial. maybe they placed the drills as close to the edge as possible, aka less abrasive hard work to be done.

( I´m still not ruling out iron tools )

edit on 22-7-2021 by anti72 because: (no reason given)

a reply to: Byrd

almost missed the link, interesting..

Unfinished sarcophagus abondoned in the Schist quarries at Wadi Hammat, red sea hills of egypt.

one can clearly see the chisel marks and even the matching surrounding.

it seems that it was abondoned because its side broke completely off during work.

so, to the stone work technicians here, would these visible chisel marks look similar to those of iron chisels? would iron chisels be strong enough to pentrate into this kind of basalt?

to my knowledge basalt is a dark, hard volcanic brittle material..as an artist I have once worked with stone and a steel chisel, so it basically is sculpted erosive. you basically slowly take away the material in a controlled manner till you near the planned form.

this is what we see here inho.

almost missed the link, interesting..

Unfinished sarcophagus abondoned in the Schist quarries at Wadi Hammat, red sea hills of egypt.

Wadi Hammamat is a quarrying area located in the Eastern Desert of Egypt. This site is noted because it is described in the first ancient topographic map known, the Turin Papyrus Map, describing a quarrying expedition prepared for Ramesses IV. Typical materials known from this site are: basalt, basanite

one can clearly see the chisel marks and even the matching surrounding.

it seems that it was abondoned because its side broke completely off during work.

so, to the stone work technicians here, would these visible chisel marks look similar to those of iron chisels? would iron chisels be strong enough to pentrate into this kind of basalt?

to my knowledge basalt is a dark, hard volcanic brittle material..as an artist I have once worked with stone and a steel chisel, so it basically is sculpted erosive. you basically slowly take away the material in a controlled manner till you near the planned form.

this is what we see here inho.

edit on 22-7-2021 by anti72 because: (no reason given)

and

originally posted by: ChaoticOrder

It seems to me scientists are vastly underestimating the tools and knowledge which went into making these objects.

It seems to me there's no realistic way of explaining how they achieved these feats unless we can admit they had some fairly advanced knowledge.

Scientists and modern stone masons have well understood the techniques of the past where Eqyptians (and other cultures) carved granite, and other stone, using the materials available to them - ample labour, copper, stone, sand, wood, water and so on. The techniques of the past have been replicated, so it can be done.

Just because we think it would be difficult to do - and it would - does not mean that someone a few thousand years ago, with plenty of time and labour could not do it. In fact we know they did, as the OP shows!

They did not have "advanced knowledge". They had the necessary knowledge.

new topics

-

God's Righteousness is Greater than Our Wrath

Religion, Faith, And Theology: 2 hours ago -

Electrical tricks for saving money

Education and Media: 5 hours ago -

VP's Secret Service agent brawls with other agents at Andrews

Mainstream News: 7 hours ago -

Sunak spinning the sickness figures

Other Current Events: 7 hours ago -

Nearly 70% Of Americans Want Talks To End War In Ukraine

Political Issues: 8 hours ago -

Late Night with the Devil - a really good unusual modern horror film.

Movies: 9 hours ago -

Cats Used as Live Bait to Train Ferocious Pitbulls in Illegal NYC Dogfighting

Social Issues and Civil Unrest: 11 hours ago

top topics

-

VP's Secret Service agent brawls with other agents at Andrews

Mainstream News: 7 hours ago, 9 flags -

Cats Used as Live Bait to Train Ferocious Pitbulls in Illegal NYC Dogfighting

Social Issues and Civil Unrest: 11 hours ago, 8 flags -

Electrical tricks for saving money

Education and Media: 5 hours ago, 4 flags -

HORRIBLE !! Russian Soldier Drinking Own Urine To Survive In Battle

World War Three: 15 hours ago, 3 flags -

Nearly 70% Of Americans Want Talks To End War In Ukraine

Political Issues: 8 hours ago, 3 flags -

Sunak spinning the sickness figures

Other Current Events: 7 hours ago, 3 flags -

Late Night with the Devil - a really good unusual modern horror film.

Movies: 9 hours ago, 2 flags -

The Good News According to Jesus - Episode 1

Religion, Faith, And Theology: 13 hours ago, 1 flags -

God's Righteousness is Greater than Our Wrath

Religion, Faith, And Theology: 2 hours ago, 0 flags

active topics

-

New whistleblower Jason Sands speaks on Twitter Spaces last night.

Aliens and UFOs • 55 • : baablacksheep1 -

VP's Secret Service agent brawls with other agents at Andrews

Mainstream News • 40 • : ThatSmellsStrange -

Cats Used as Live Bait to Train Ferocious Pitbulls in Illegal NYC Dogfighting

Social Issues and Civil Unrest • 20 • : Asher47 -

Nearly 70% Of Americans Want Talks To End War In Ukraine

Political Issues • 12 • : Asher47 -

Electrical tricks for saving money

Education and Media • 4 • : Lumenari -

DONALD J. TRUMP - 2024 Candidate for President - His Communications to Americans and the World.

2024 Elections • 514 • : WeMustCare -

The Acronym Game .. Pt.3

General Chit Chat • 7744 • : bally001 -

Truth Social goes public, be careful not to lose your money

Mainstream News • 128 • : Astyanax -

Sunak spinning the sickness figures

Other Current Events • 5 • : glen200376 -

SETI chief says US has no evidence for alien technology. 'And we never have'

Aliens and UFOs • 44 • : MikeDeGrasseTyson