It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

12

share:

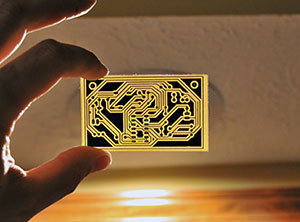

I'm looking to start a new hobby, PCB etching. I've been reading up on it the last few days and it looks kind of fun. So far, I've got all the stuff I need, just a few items left to purchase online.

Still unsure which ones to buy and was hoping that someone who actually does it could help me out. NOT looking to go expensive, as I'm not sure if this is something I want to continue to do. But I think it would be something I'd like to try it out.

I need a micro drill, but am unsure if you really need that or not. And if I do need it, I don't know which one to get. Do I need a small drill press for sure just to try this? And I saw that some people use good quality magazine pages versus the transfer paper for laser printers, not sure which is better or why.

As I said, I am trying to go low tech on this for starters. I found a video and website that shows a pretty basic way to make one. And, also, I am probably not going to be using what I make in any electronic device (I don't think...lol). But I still need it to work.

So, I know it's a long shot, but is there anyone who does this type of work that can tell me the bare bones basics I need or can get by with in order to try this out?

Video explains the etching process:

website

From what I've read, there are several different ways to etch a board. I think for simplicities sake, I'll probably be using the one in the video.

Also found this to use for the etching process, in place of Ferric chloride:

Vinager, hydrogen peroxide, salt. 100ml/100ml/7ml salt. Is this a good substitute?

Thanks to anyone who can help!

blend

edit on 19-11-2017 by blend57 because: Always an edit : /

a reply to: blend57

Well, first off, I'm sorry to say I can't help you with this as I have never even heard of it before.. I just wanted to say though that it never ceases to amaze me the depth, diversity and propensity of humans to create and play when given the freedom, time and resources to do so..

Best of luck with your new hobby/interest and I hope there's folks along soon that can be more helpful than me

Well, first off, I'm sorry to say I can't help you with this as I have never even heard of it before.. I just wanted to say though that it never ceases to amaze me the depth, diversity and propensity of humans to create and play when given the freedom, time and resources to do so..

Best of luck with your new hobby/interest and I hope there's folks along soon that can be more helpful than me

a reply to: FauxMulder

Thanks, I looked at those as well while I was searching online. But if I don't need the micro drill or the press, I have everything I need at home already and can get started..lol. (still would order those later if I found this was something I'd want to continue doing)

a reply to: Indrasweb

It was a toss up between PCB etching and lithography. But I can do the etching in the house and the lithography seems like it needs more space. Video below shows what that is...

Online PDF about its history:

sites.tech.uh.edu...

Thanks for the responses and help!

blend

Thanks, I looked at those as well while I was searching online. But if I don't need the micro drill or the press, I have everything I need at home already and can get started..lol. (still would order those later if I found this was something I'd want to continue doing)

a reply to: Indrasweb

It was a toss up between PCB etching and lithography. But I can do the etching in the house and the lithography seems like it needs more space. Video below shows what that is...

Online PDF about its history:

sites.tech.uh.edu...

Thanks for the responses and help!

blend

a reply to: blend57

Photo etching is the way to go. I like the process in the video, I think you could make some pretty intricate boards with it. As long as you could make the pattern.

Who knows, You may even want to start using programs like Solidworks to start designing your patterns even just for practice.

Get a micro drill. There is no way your going to get the precision you need without it. Get a dremel tool with a drill press and some pin bits.

And don't forget to have fun!

Photo etching is the way to go. I like the process in the video, I think you could make some pretty intricate boards with it. As long as you could make the pattern.

Who knows, You may even want to start using programs like Solidworks to start designing your patterns even just for practice.

Get a micro drill. There is no way your going to get the precision you need without it. Get a dremel tool with a drill press and some pin bits.

And don't forget to have fun!

a reply to: blend57

I've used LPKF (you'll go through LPFK USA). The drill will etch a negative of the design. Cheap will still run a couple grand. Very cheap will be few hundred (Ebay). The drill bits and copper costs can add up too. The cheap ones can't do etches any smaller than 8 mils; this makes all of your modern IC footprints difficult or impossible. Passives, DPAKs, and SOT packages would be pretty easy. Some come with their own CAD tools, some will take gerbers from just about anything (free Eagle).

If you're into designing your own boards at home, you may be better off out sourcing the PCB fab at a prototype shop. You can get some pretty cheap boards, 2-4 layer, within a week.

You'll need a universal milling tool bit, an end mill, and a contour router bit.

You'll need a disposable cover lay (sits under the copper clad board.

You'll have to use thru-hold pads fill with wire or cut pins, soldered through, to approximate vias unless you invest in a machine for plating ($$ and toxic).

If you do go the drill route, pro tip: bit will last twice as long as they advertise to so throw away too soon.

I've used LPKF (you'll go through LPFK USA). The drill will etch a negative of the design. Cheap will still run a couple grand. Very cheap will be few hundred (Ebay). The drill bits and copper costs can add up too. The cheap ones can't do etches any smaller than 8 mils; this makes all of your modern IC footprints difficult or impossible. Passives, DPAKs, and SOT packages would be pretty easy. Some come with their own CAD tools, some will take gerbers from just about anything (free Eagle).

If you're into designing your own boards at home, you may be better off out sourcing the PCB fab at a prototype shop. You can get some pretty cheap boards, 2-4 layer, within a week.

You'll need a universal milling tool bit, an end mill, and a contour router bit.

You'll need a disposable cover lay (sits under the copper clad board.

You'll have to use thru-hold pads fill with wire or cut pins, soldered through, to approximate vias unless you invest in a machine for plating ($$ and toxic).

If you do go the drill route, pro tip: bit will last twice as long as they advertise to so throw away too soon.

edit on 19-11-2017 by

AntiDoppleganger because: (no reason given)

originally posted by: trontech

a reply to: blend57

Photo etching is the way to go. I like the process in the video, I think you could make some pretty intricate boards with it. As long as you could make the pattern.

Who knows, You may even want to start using programs like Solidworks to start designing your patterns even just for practice.

Get a micro drill. There is no way your going to get the precision you need without it. Get a dremel tool with a drill press and some pin bits.

And don't forget to have fun!

I think I read you can print the patterns offline somewhere. At least until I get a better understanding of the whole thing, I'll probably do that. Ok, I'll grab a micro drill then...I have the soldering iron and dremel already. Forgot that I need to get the copper sheets anyways. Just gonna grab a cheap drill to start with and then upgrade later.

Thanks for the help!

originally posted by: AntiDoppleganger

a reply to: blend57

If you're into designing your own boards at home, you may be better off out sourcing the PCB fab at a prototype shop. You can get some pretty cheap boards, 2-4 layer, within a week.

This is the only part of your post that made any sense to me

It was a very informative and well thought out post, you just have a ton of knowledge and I have a weekend of reading up on it.

I would like to make the boards myself, as I said, that's the part that seems like it would be fun. I thought I could use them in another project, and if it turned out, I could make some more. But I do need them to be working, so, I don't know if the PCB etchings would be the way to go. All the commentary on them said they work though.

Thanks for the information, I really do appreciate it and I appreciate the drill tip as well

blend

a reply to: intrptr

I'm making boards for electronics. But at first I just want to get the process down I guess. So, if they don't work for the first few tries, that's ok. But I will need them to work eventually. I'm looking to incorporate them into another project eventually.

They use this process in jewelry making as well I read. I guess I'll need to read up a bit more on the toxicity of it. No one mentioned any concerns about that other than a face mask and gloves for protection. (unless I missed it somehow)

Thanks for letting me know!

blend

I'm making boards for electronics. But at first I just want to get the process down I guess. So, if they don't work for the first few tries, that's ok. But I will need them to work eventually. I'm looking to incorporate them into another project eventually.

They use this process in jewelry making as well I read. I guess I'll need to read up a bit more on the toxicity of it. No one mentioned any concerns about that other than a face mask and gloves for protection. (unless I missed it somehow)

Thanks for letting me know!

blend

You can use a black magic marker on the copper side to mark your circuit out, I have done this multiple times. As far as the drill you can use a small

hand drill that you spin with your fingers it is only a few bucks. Here is a link for electronic stuff to get started.

www.discovercircuits.com...

a reply to: blend57

a reply to: blend57

a reply to: gimcrackery

Just make sure you inspect them well. It's easy to miss an unintended bridge or break.

You'll need a good quality loupe when you get to the smaller runs.

Just make sure you inspect them well. It's easy to miss an unintended bridge or break.

You'll need a good quality loupe when you get to the smaller runs.

a reply to: blend57

You have a circuit already designed and need to lay it out on a PCB? Usually thats the production phase. If you are making one two you can do without fabricating circuit boards.

You could drill your own bread board and hand wire it from component to component, power and ground.

You might have already done that and be ready for the next phase.

Yah, its very toxic. Etching copper traces from blank fab is done with acids. Along with the gloves and mask you might want to consider a vented glove box.

You have a circuit already designed and need to lay it out on a PCB? Usually thats the production phase. If you are making one two you can do without fabricating circuit boards.

You could drill your own bread board and hand wire it from component to component, power and ground.

You might have already done that and be ready for the next phase.

Yah, its very toxic. Etching copper traces from blank fab is done with acids. Along with the gloves and mask you might want to consider a vented glove box.

Ok..I can't find my dremel..probably gave it away. Lol. So, I need to get a new one. Was looking at them and found a dremel drill press. Think I am

going to get that unless there is a reason why I shouldn't?

Drill press

And these are the drills I found. Not sure if I need this with the Dremel press, or if I can use one of these instead of the press??

Hand drill

or this one (I'm thinking this one will accomplish all I need without buying anything else. But I'm unsure, as usual):

Mini electric drill

All various prices. At any rate, I'll have to wait a few days to get this started. I just ordered the copper and have to wait for that. Hopefully I can figure out what drill I need and get that purchased today as well.

Thanks again everyone for all your help, tips, and sharing your expertise. I will post some of the finished results once I get all the supplies and get a few boards done.

blend

Drill press

And these are the drills I found. Not sure if I need this with the Dremel press, or if I can use one of these instead of the press??

Hand drill

or this one (I'm thinking this one will accomplish all I need without buying anything else. But I'm unsure, as usual):

Mini electric drill

All various prices. At any rate, I'll have to wait a few days to get this started. I just ordered the copper and have to wait for that. Hopefully I can figure out what drill I need and get that purchased today as well.

Thanks again everyone for all your help, tips, and sharing your expertise. I will post some of the finished results once I get all the supplies and get a few boards done.

blend

edit on 19-11-2017 by blend57 because: Always an edit : /

new topics

-

whistleblower Captain Bill Uhouse on the Kingman UFO recovery

Aliens and UFOs: 3 hours ago -

1980s Arcade

General Chit Chat: 5 hours ago -

Deadpool and Wolverine

Movies: 6 hours ago -

Teenager makes chess history becoming the youngest challenger for the world championship crown

Other Current Events: 7 hours ago -

CIA botched its handling of sexual assault allegations, House intel report says

Breaking Alternative News: 8 hours ago -

Lawsuit Seeks to ‘Ban the Jab’ in Florida

Diseases and Pandemics: 10 hours ago

top topics

-

Lawsuit Seeks to ‘Ban the Jab’ in Florida

Diseases and Pandemics: 10 hours ago, 20 flags -

Starburst galaxy M82 - Webb Vs Hubble

Space Exploration: 12 hours ago, 12 flags -

The Superstition of Full Moons Filling Hospitals Turns Out To Be True!

Medical Issues & Conspiracies: 14 hours ago, 8 flags -

CIA botched its handling of sexual assault allegations, House intel report says

Breaking Alternative News: 8 hours ago, 8 flags -

whistleblower Captain Bill Uhouse on the Kingman UFO recovery

Aliens and UFOs: 3 hours ago, 6 flags -

15 Unhealthiest Sodas On The Market

Health & Wellness: 13 hours ago, 5 flags -

Teenager makes chess history becoming the youngest challenger for the world championship crown

Other Current Events: 7 hours ago, 3 flags -

Deadpool and Wolverine

Movies: 6 hours ago, 3 flags -

1980s Arcade

General Chit Chat: 5 hours ago, 3 flags

active topics

-

They Killed Dr. Who for Good

Rant • 61 • : Cymru -

How ageing is" immune deficiency"

Medical Issues & Conspiracies • 26 • : RookQueen2 -

The Democrats Take Control the House - Look what happened while you were sleeping

US Political Madness • 105 • : SchrodingersRat -

Starburst galaxy M82 - Webb Vs Hubble

Space Exploration • 4 • : SchrodingersRat -

Non-Human Operate Within The Visual Spectrum 'We Cannot See' - ULTRATERRESTRIALS EXIST!

Paranormal Studies • 136 • : burritocat -

New whistleblower Jason Sands speaks on Twitter Spaces last night.

Aliens and UFOs • 39 • : RookQueen2 -

23,000 Dead People Registered Within a Two Week Period In One State

US Political Madness • 39 • : Audreagassulke -

1980s Arcade

General Chit Chat • 7 • : Freeborn -

Europe declares war on Russia?

World War Three • 59 • : Freeborn -

George Knapp AMA on DI

Area 51 and other Facilities • 38 • : theshadowknows

12