It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

share:

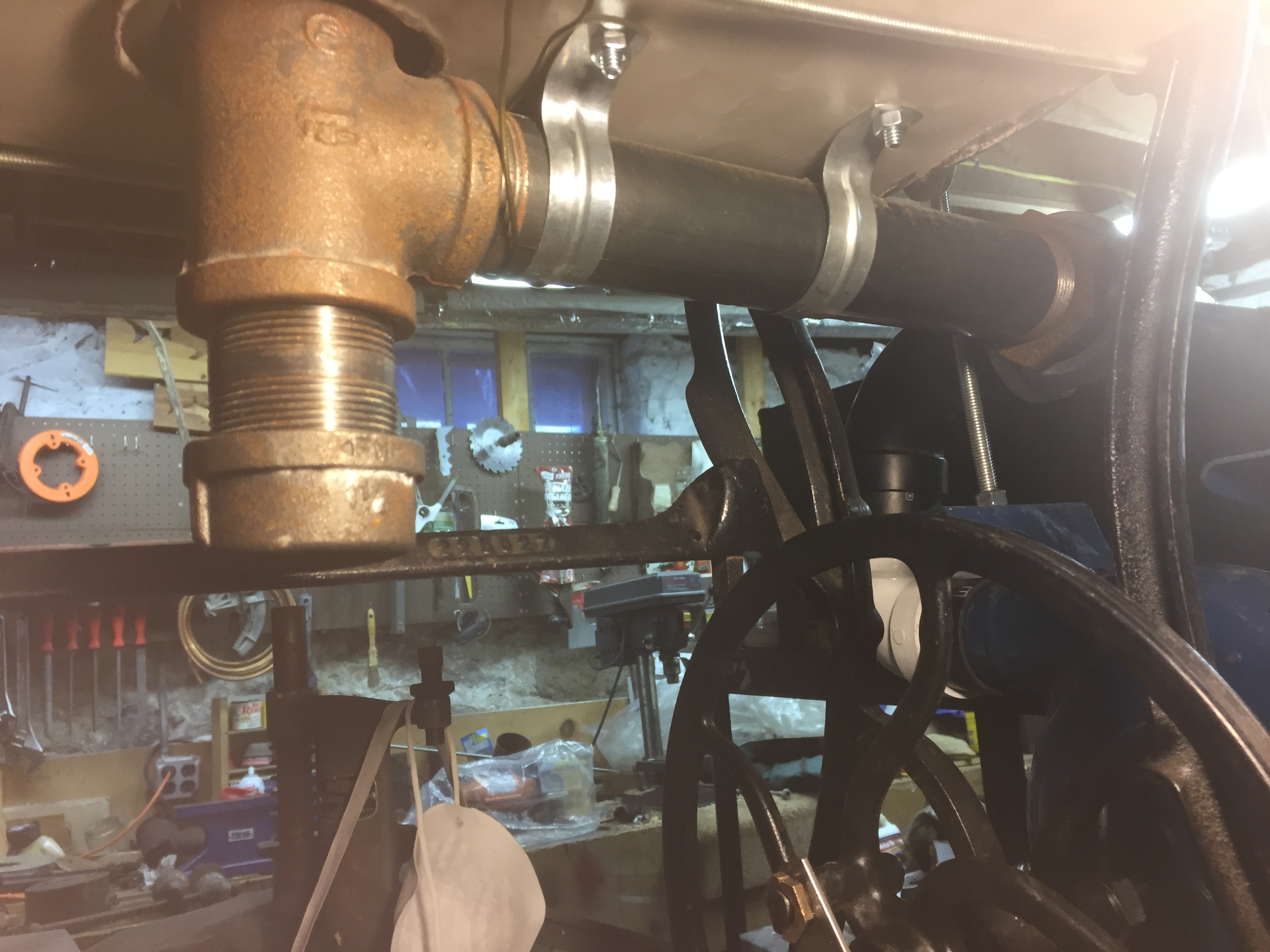

Built this from a Wheeler Wilson treadle sewing machine base to create a pedal powered forge. Found the blower on Amazon.

The ducting channels air through an "ash guard", sheet metal, into a fire-pot.

Plan to counter weight the flywheel to help spin the wheel past the dead center point on the treadle stroke, where the treadle often jams up.

The lower cap on the "T" fitting is an ash clean-out. Machined the threads off a close nipple above the "T" fitting to form a quick disconnect into the fire-pot.

A cast iron fireplace grate forms the frame for the forge, which is lined with firebrick. My original fire-pot was an aluminum bowl insulated with fireplace mortar, rated to 2000 Deg F. Although this worked, it was problematic, requiring constant repair and eventually burned through. Replaced it with a 12 inch cast iron frying pan. The quick disconnect feature described earlier allows the removal of the grate, which is effectively the "forge", from the treadle-blower base. As the firebrick shields the treadle frame from heat, I can put the frame away while the fire grate cools off separately

I fire with coal and generate sufficient heat to forge tool steel.

Have more photos, but can't load them, every time I try they don't appear in the uploaded box.

Bummer, my anvil was cast in 1819, rings true and illustrates the early English method of measuring an anvil's weight.

In a survivalist setting railroad iron will suffice for an anvil, however Harbor Freight sells Chinese cast mooring...I mean anvils, but even a bad Chinese anvil is better than RR iron.

a reply to: Wreckclues

Very nice!!! I built my 1st propane forge a couple months ago pretty primitive but it works, I want to build a Coal forge but I live in Cali and no one understands the word Coal would have to buy from the net. I Love moving metal made a knife so far and working on some Ornate Brackets to hang some mirrors.

Very nice!!! I built my 1st propane forge a couple months ago pretty primitive but it works, I want to build a Coal forge but I live in Cali and no one understands the word Coal would have to buy from the net. I Love moving metal made a knife so far and working on some Ornate Brackets to hang some mirrors.

edit on 5/24/2017 by Gargoyle91 because: (no reason given)

a reply to: Wreckclues Good job!! How much was the cost of the blower? Seems new, brand new. Is anyone still manufacture

mechanical ones in that century, lol.

I have always liked the use of a treadle set-up for machines. There is a museum in Berea,Ky. that has many treadle powered tools. Wood lathes, table

saws and many other man-powered machines from around the country are there. I haven't been there in a long time so I don't know of any new

additions.

There is a man who was a industrial arts teacher on the web named MR PETE. He has many episode of metal working on his website that may be of use to you. There is some vids of forging and casting that are very interesting. He does sand molding in his garage with easily available tools which you may find useful.

There is a man who was a industrial arts teacher on the web named MR PETE. He has many episode of metal working on his website that may be of use to you. There is some vids of forging and casting that are very interesting. He does sand molding in his garage with easily available tools which you may find useful.

edit on 24-5-2017 by buddah6 because: Superior pain medication and no coffee.

a reply to: Argentbenign

It is brand new, in fact you can by everything you need from Amazon...including the forge.

www.amazon.com...

How much was the cost of the blower? Seems new

It is brand new, in fact you can by everything you need from Amazon...including the forge.

www.amazon.com...

a reply to: Gargoyle91

Amazon has 16 lb bags for about $23. We still have folks around here who heat with coal so I can purchase it locally.

would have to buy from the net

Amazon has 16 lb bags for about $23. We still have folks around here who heat with coal so I can purchase it locally.

a reply to: Wreckclues

My problem would be just how much Coal I need for a job - How long will 16lbs burn? I should know we used to heat with coal but I was Knew high in Tennessee used to go to the Coal mines and get truck loads with my Grandpa.

My problem would be just how much Coal I need for a job - How long will 16lbs burn? I should know we used to heat with coal but I was Knew high in Tennessee used to go to the Coal mines and get truck loads with my Grandpa.

a reply to: Wreckclues

Nice. Creative way to foot pedal the blower by re-purposing a thing from the past.

Looks sweet.

Nice. Creative way to foot pedal the blower by re-purposing a thing from the past.

Looks sweet.

originally posted by: Wreckclues

Built this from a Wheeler Wilson treadle sewing machine base to create a pedal powered forge. Found the blower on Amazon.

The ducting channels air through an "ash guard", sheet metal, into a fire-pot.

Plan to counter weight the flywheel to help spin the wheel past the dead center point on the treadle stroke, where the treadle often jams up.

The lower cap on the "T" fitting is an ash clean-out. Machined the threads off a close nipple above the "T" fitting to form a quick disconnect into the fire-pot.

A cast iron fireplace grate forms the frame for the forge, which is lined with firebrick. My original fire-pot was an aluminum bowl insulated with fireplace mortar, rated to 2000 Deg F. Although this worked, it was problematic, requiring constant repair and eventually burned through. Replaced it with a 12 inch cast iron frying pan. The quick disconnect feature described earlier allows the removal of the grate, which is effectively the "forge", from the treadle-blower base. As the firebrick shields the treadle frame from heat, I can put the frame away while the fire grate cools off separately

I fire with coal and generate sufficient heat to forge tool steel.

Have more photos, but can't load them, every time I try they don't appear in the uploaded box.

Bummer, my anvil was cast in 1819, rings true and illustrates the early English method of measuring an anvil's weight.

In a survivalist setting railroad iron will suffice for an anvil, however Harbor Freight sells Chinese cast mooring...I mean anvils, but even a bad Chinese anvil is better than RR iron.

You my friend are what keeps me coming back to ATS.

Absolutely brilliant! I'm impressed

a reply to: RogueWaterC1

Historical farming. I manage a Conservation trust that maintains an 1867 dairy barn. So I'm forging general farm implements, hooks, hinges, brackets, just trying to keep the upper floor and lofts as historically accurate as possible. Although, I'm hooked on "Forged In Fire" and as soon as I can build an oil quench I'll start experiment with blades

Historical farming. I manage a Conservation trust that maintains an 1867 dairy barn. So I'm forging general farm implements, hooks, hinges, brackets, just trying to keep the upper floor and lofts as historically accurate as possible. Although, I'm hooked on "Forged In Fire" and as soon as I can build an oil quench I'll start experiment with blades

a reply to: Wreckclues

That's hot....!

I've wanted to build my own forge for years. Someday. Great ingenuity show here.

That's hot....!

I've wanted to build my own forge for years. Someday. Great ingenuity show here.

Looks like it will work pretty well. I have a cast iron forge in the garage, and all the blacksmith tools too. I got it from my stepfathers garage

after he died, it is actually both mine and my brothers. Half the blacksmith tools I collected over the years from rummage sales and from older

people I knew who gave them to me.

I even studied how to use it but never tried it yet. It uses charcoal or coal or even some hardwood clippings would work.

I even studied how to use it but never tried it yet. It uses charcoal or coal or even some hardwood clippings would work.

a reply to: rickymouse

Just picked up an old Farrier's or possibly Riveters forge from my local "Mantique" store, un-marked save for "Clay Forge Before Using" cast in the base, came with a rusted out blower and most resembles a Champion. Blower gears are salvageable, but I'll have to drill out and machine new pinions. The bulk of my blacksmith tools came from an old neighbor who collected Western Memorabilia, the guy had a chuck wagon supporting his basement staircase and a complete Blacksmith shop set up in an anti-room. When he moved he gave me everything he didn't have a provenance on. Been sitting on those things for 30+ years, figured why wait any longer, no better time than the present.

I have a cast iron forge in the garage

Just picked up an old Farrier's or possibly Riveters forge from my local "Mantique" store, un-marked save for "Clay Forge Before Using" cast in the base, came with a rusted out blower and most resembles a Champion. Blower gears are salvageable, but I'll have to drill out and machine new pinions. The bulk of my blacksmith tools came from an old neighbor who collected Western Memorabilia, the guy had a chuck wagon supporting his basement staircase and a complete Blacksmith shop set up in an anti-room. When he moved he gave me everything he didn't have a provenance on. Been sitting on those things for 30+ years, figured why wait any longer, no better time than the present.

edit on 5/24/2017 by Wreckclues because: spelling and

grammar

a reply to: JinMI

With the firebrick and ash guard it's quite cool too.

Why slave over a hot forge when you can kick back with a burger in one hand and a hard cider in the other all the while pedaling the treadle

That's hot....!

With the firebrick and ash guard it's quite cool too.

Why slave over a hot forge when you can kick back with a burger in one hand and a hard cider in the other all the while pedaling the treadle

edit on 5/24/2017 by Wreckclues because: Damn spell check!

Well, when you get it finished, it will be an elaborate marshmallow roaster. Thirty years in the garage, I wonder if you will ever actually make

something with it? If you are like me, you will get it all ready and fire it up to see if it works then go on to fixing something else up.

a reply to: rickymouse

The forge is done, fired it about 10 times last year, the tools were hanging around my barn for 30 years.

The forge is done, fired it about 10 times last year, the tools were hanging around my barn for 30 years.

new topics

-

Supreme Court Oral Arguments 4.25.2024 - Are PRESIDENTS IMMUNE From Later Being Prosecuted.

Above Politics: 18 minutes ago -

Krystalnacht on today's most elite Universities?

Social Issues and Civil Unrest: 27 minutes ago -

Chris Christie Wishes Death Upon Trump and Ramaswamy

Politicians & People: 54 minutes ago -

University of Texas Instantly Shuts Down Anti Israel Protests

Education and Media: 3 hours ago -

Any one suspicious of fever promotions events, major investor Goldman Sachs card only.

The Gray Area: 5 hours ago -

God's Righteousness is Greater than Our Wrath

Religion, Faith, And Theology: 9 hours ago

top topics

-

VP's Secret Service agent brawls with other agents at Andrews

Mainstream News: 14 hours ago, 11 flags -

Nearly 70% Of Americans Want Talks To End War In Ukraine

Political Issues: 14 hours ago, 5 flags -

Sunak spinning the sickness figures

Other Current Events: 14 hours ago, 5 flags -

Electrical tricks for saving money

Education and Media: 12 hours ago, 4 flags -

Late Night with the Devil - a really good unusual modern horror film.

Movies: 16 hours ago, 3 flags -

Krystalnacht on today's most elite Universities?

Social Issues and Civil Unrest: 27 minutes ago, 3 flags -

Any one suspicious of fever promotions events, major investor Goldman Sachs card only.

The Gray Area: 5 hours ago, 2 flags -

University of Texas Instantly Shuts Down Anti Israel Protests

Education and Media: 3 hours ago, 2 flags -

Supreme Court Oral Arguments 4.25.2024 - Are PRESIDENTS IMMUNE From Later Being Prosecuted.

Above Politics: 18 minutes ago, 1 flags -

Chris Christie Wishes Death Upon Trump and Ramaswamy

Politicians & People: 54 minutes ago, 0 flags

active topics

-

University of Texas Instantly Shuts Down Anti Israel Protests

Education and Media • 41 • : CriticalStinker -

Remember These Attacks When President Trump 2.0 Retribution-Justice Commences.

2024 Elections • 56 • : WeMustCare -

Candidate TRUMP Now Has Crazy Judge JUAN MERCHAN After Him - The Stormy Daniels Hush-Money Case.

Political Conspiracies • 743 • : WeMustCare -

British TV Presenter Refuses To Use Guest's Preferred Pronouns

Education and Media • 148 • : Consvoli -

Nearly 70% Of Americans Want Talks To End War In Ukraine

Political Issues • 64 • : FlyersFan -

VP's Secret Service agent brawls with other agents at Andrews

Mainstream News • 44 • : ByeByeAmericanPie -

New whistleblower Jason Sands speaks on Twitter Spaces last night.

Aliens and UFOs • 59 • : baablacksheep1 -

1980s Arcade

General Chit Chat • 27 • : alwaysbeenhere2 -

Skinwalker Ranch and the Mystery 1.6GHz Signal

Aliens and UFOs • 143 • : Ophiuchus1 -

"We're All Hamas" Heard at Columbia University Protests

Social Issues and Civil Unrest • 281 • : marg6043