It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

share:

reply to post by anoncoholic

Are you able to provide a basic diagram for what you're describing? Sorry having a little difficulty visualising what you're describing, most likely due to my lack of engineering knowledge, but yeah, if you can provide a basic diagram that would be great!!

Are you able to provide a basic diagram for what you're describing? Sorry having a little difficulty visualising what you're describing, most likely due to my lack of engineering knowledge, but yeah, if you can provide a basic diagram that would be great!!

reply to post by Im a Marty

I watched the video again and the wheel in water is only using a single nitinol loop in its revolutionary cycle so I am wondering why they also didn't use more on the other diameters of the wheel... perhaps they had since that video I dunno but it seemed obvious that if one makes it go round, two or more would increase the motive force.

As far as drawing, my drawing board is in my mind and expressing it in words might not be doing it justice. I have been "visualizing" my own concept for years and understand it better than this concept which is entirely new to me so I am sure my first thoughts will be revised the more I look at it but for a start, you are trying to turn a generator... why not build the generator into the design itself. The drag of a separate generator would be eliminated entirely since it would all be a single entity rather than a dual action.

In your first model (I can't fully fathom the second revision yet as I haven't spent much time on it, but I will and see if I can draw a concept with words for you.

If you guys are flexible, I have a design that will spin without nitinol so it could be modified to utilize nitinol I am thinking.

A question I have is the direction of turns on the windings themselves... I assume the layout is all of the same direction twist which makes it travel in one direction only but that is using a coil design since that gives the most efficient reaction... can the length of wire be longer yet still reside within the same space? I think so, if the winding weren't in a coil around a nail for example but around a cone shape instead... or perhaps like the spiral of tracks on a cd.

Like I said, this is all new to me and the more I think about it the more concepts take shape (sorry for the pun)

but I am intrigued by the properties.

I'll U2U if I can offer something conclusive but will have to give this more thought in combining material with geometry and geographic layout of the concepts.

it does look promising

I watched the video again and the wheel in water is only using a single nitinol loop in its revolutionary cycle so I am wondering why they also didn't use more on the other diameters of the wheel... perhaps they had since that video I dunno but it seemed obvious that if one makes it go round, two or more would increase the motive force.

As far as drawing, my drawing board is in my mind and expressing it in words might not be doing it justice. I have been "visualizing" my own concept for years and understand it better than this concept which is entirely new to me so I am sure my first thoughts will be revised the more I look at it but for a start, you are trying to turn a generator... why not build the generator into the design itself. The drag of a separate generator would be eliminated entirely since it would all be a single entity rather than a dual action.

In your first model (I can't fully fathom the second revision yet as I haven't spent much time on it, but I will and see if I can draw a concept with words for you.

If you guys are flexible, I have a design that will spin without nitinol so it could be modified to utilize nitinol I am thinking.

A question I have is the direction of turns on the windings themselves... I assume the layout is all of the same direction twist which makes it travel in one direction only but that is using a coil design since that gives the most efficient reaction... can the length of wire be longer yet still reside within the same space? I think so, if the winding weren't in a coil around a nail for example but around a cone shape instead... or perhaps like the spiral of tracks on a cd.

Like I said, this is all new to me and the more I think about it the more concepts take shape (sorry for the pun)

but I am intrigued by the properties.

I'll U2U if I can offer something conclusive but will have to give this more thought in combining material with geometry and geographic layout of the concepts.

it does look promising

edit on 2-7-2012 by anoncoholic because: typo

edit on 2-7-2012 by anoncoholic because: typo

TO answer a few of your questions. The reason we aren't using a built in generator is that you can buy something off the shelf that's so efficient

there's no way you could realistically match it winding your own. For two this is a proof of concept test model. What that means is we want to make

it as modular as possible so we can test multiple configurations without having to rebuild the entire setup. It also means we are using as much in the

way of off the shelf parts as we can possibly get. This will save us time,money, and aggravation.

Now onto your idea. I"m having trouble envisioning it completely. So you want to build a motor like teh one in the 20 minute nitinol video.... but you want to do something else to it.... am I correct so far?

It would really help if you could clarify your description some and explain the idea from square one. You keep referencing the other motor and etc but I don't know what other motor you want me to envision.

Now onto your idea. I"m having trouble envisioning it completely. So you want to build a motor like teh one in the 20 minute nitinol video.... but you want to do something else to it.... am I correct so far?

It would really help if you could clarify your description some and explain the idea from square one. You keep referencing the other motor and etc but I don't know what other motor you want me to envision.

reply to post by Im a Marty

dear sir,

I need to know about this more please contact me on.

e-mail. [email protected]

dear sir,

I need to know about this more please contact me on.

e-mail. [email protected]

Originally posted by dentco

reply to post by Im a Marty

dear sir,

I need to know about this more please contact me on.

e-mail. [email protected]

Hey there Dentco... wrote you an e-mail.

On a side note, are you associated with Dentco

I was doing some thinking about this device today and I came to realize that maybe I was looking at this device teh wrong way. After I consult with my

fellow developers I'll maybe detail my thoughts more fully in this thread. For now watch this space as there could be new developments very shortly.

awesome, just to iterate, Rogue and I have talked in skype, and to just let you all know that we have exciting developments underway, posts to come

Hi Marty ,

It's adnan from Pakistan I am send you several e-mail but sorry to say not any single reply would you please give me reply or send me Skype id?

It's adnan from Pakistan I am send you several e-mail but sorry to say not any single reply would you please give me reply or send me Skype id?

Hello: any buddy know's how make shape setting tools for NITI wires?

please send me details on : [email address removed]

thanks,

please send me details on : [email address removed]

thanks,

edit on 10/6/2012 by 12m8keall2c because: Please don't post personal contact info on the boards

reply to post by dentco

It is very simple. Build a form (jig) that can withstand repeated heating without corrosion in the shape of the item you wish to train. Be sure to secure the Nitinol tightly for best results. Nitinol trains better when annealed under strain. As an example, if you wish to train a piece of wire to be a spring, cut a length of solid metal rod in the diameter of the spring you wish to train. Drill and thread a screw near each end of the rod, and on the side of it. Then make a wrap of Nitinol around one of the screws, and tighten the screw securely into the side of the rod with the Nitinol wrapped around it. Now make as many wraps around the rod with your Nitinol to develop the length of your spring. At the end of the wraps secure the final end of the Nitinol around the second threaded screw, and tighten securely. The Nitinol needs to be trained (annealed) in the oven so that it cannot move on the training rod you built, and by securing it between these two screws, you will have accomplished this.

Experiment with different Temp/Time combinations in the oven. Whichever combination you choose, you are ultimately looking for a color of between blue and purple on the Nitinol wire in the oven. It will slowly change color during training (annealing). To be able to visually see the color change, you must first start off with Nitinol wire that has had the outer green oxide removed so that it starts out in its original silver color. If you are using Nitinol wire that still has the green oxide layer on it, the best way to do this is with an acid bath, but you may lightly sand off a small area of the wire to use as a "color window". Use one end of the wire that you intend to cut off, because the very act of sanding the Nitinol can disturb the crystalline structure, and reduce the capability of the wire. Most of the wire available on the market already has this green oxide layer removed, so this may process will usually not be necessary.

Preheat your oven well before introducing the Nitinol into the oven. A good Time/Temp combination to start with would be about 550 degrees Celsius at 15 minutes for 25 mil wire. Verify the color at this time to see if it is near purplish-blue in color. After the time period in the oven, remove the spring form without touching the wire on it, and allow it to cool slowly on its own. Do not quench in water.

After the wire has cooled completely, remove the wire from your rod and straighten the wire out. It will be as soft as lead. Then stab it into a hot water bath and it will immediately become a strong spring. A spring that is only a spring when you want it to be one. It may also be activated into a spring using a light electrical current, but be careful to not overheat it with too much current, or the wire will be damaged beyond repair.

This same method may be used to train Nitinol in just about any other shape as well. Just be sure to secure your Nitinol tightly in the shape you wish to obtain.

It is very simple. Build a form (jig) that can withstand repeated heating without corrosion in the shape of the item you wish to train. Be sure to secure the Nitinol tightly for best results. Nitinol trains better when annealed under strain. As an example, if you wish to train a piece of wire to be a spring, cut a length of solid metal rod in the diameter of the spring you wish to train. Drill and thread a screw near each end of the rod, and on the side of it. Then make a wrap of Nitinol around one of the screws, and tighten the screw securely into the side of the rod with the Nitinol wrapped around it. Now make as many wraps around the rod with your Nitinol to develop the length of your spring. At the end of the wraps secure the final end of the Nitinol around the second threaded screw, and tighten securely. The Nitinol needs to be trained (annealed) in the oven so that it cannot move on the training rod you built, and by securing it between these two screws, you will have accomplished this.

Experiment with different Temp/Time combinations in the oven. Whichever combination you choose, you are ultimately looking for a color of between blue and purple on the Nitinol wire in the oven. It will slowly change color during training (annealing). To be able to visually see the color change, you must first start off with Nitinol wire that has had the outer green oxide removed so that it starts out in its original silver color. If you are using Nitinol wire that still has the green oxide layer on it, the best way to do this is with an acid bath, but you may lightly sand off a small area of the wire to use as a "color window". Use one end of the wire that you intend to cut off, because the very act of sanding the Nitinol can disturb the crystalline structure, and reduce the capability of the wire. Most of the wire available on the market already has this green oxide layer removed, so this may process will usually not be necessary.

Preheat your oven well before introducing the Nitinol into the oven. A good Time/Temp combination to start with would be about 550 degrees Celsius at 15 minutes for 25 mil wire. Verify the color at this time to see if it is near purplish-blue in color. After the time period in the oven, remove the spring form without touching the wire on it, and allow it to cool slowly on its own. Do not quench in water.

After the wire has cooled completely, remove the wire from your rod and straighten the wire out. It will be as soft as lead. Then stab it into a hot water bath and it will immediately become a strong spring. A spring that is only a spring when you want it to be one. It may also be activated into a spring using a light electrical current, but be careful to not overheat it with too much current, or the wire will be damaged beyond repair.

This same method may be used to train Nitinol in just about any other shape as well. Just be sure to secure your Nitinol tightly in the shape you wish to obtain.

OmegaLogos

reply to post by Im a Marty

Explanation: S&F!

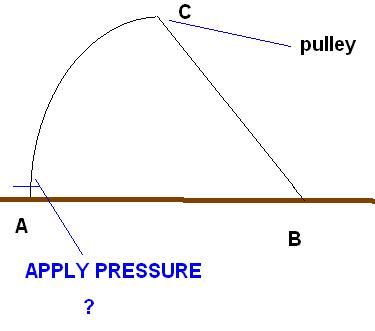

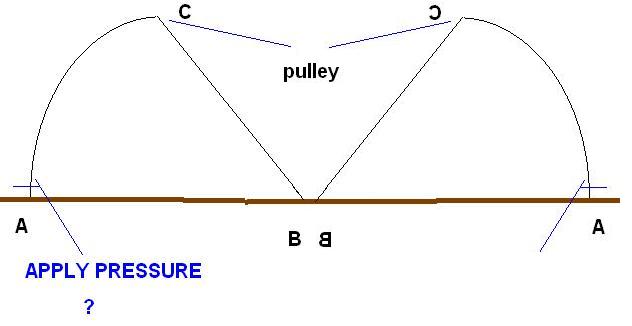

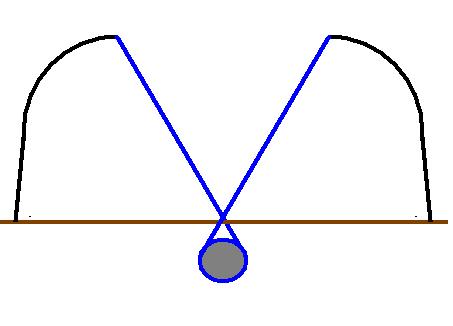

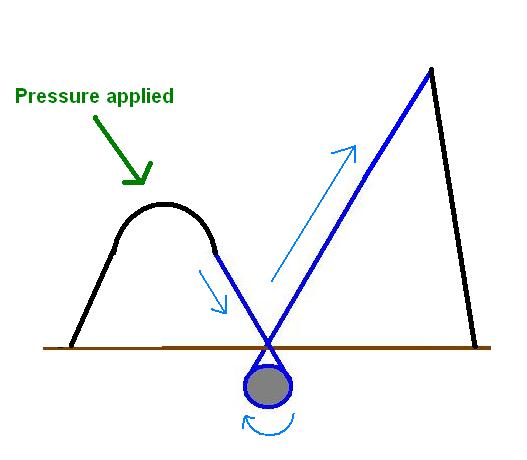

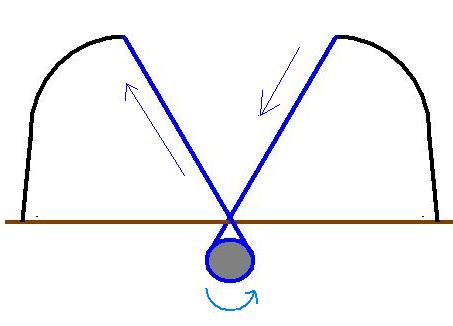

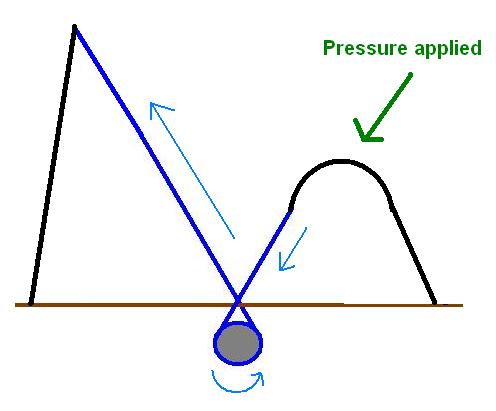

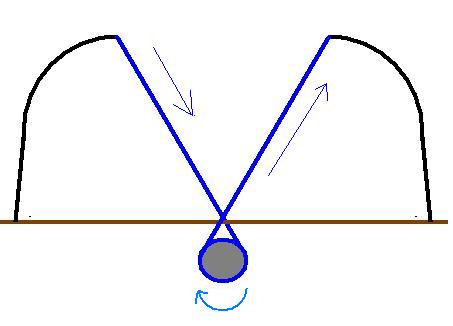

OK ... here are the VERY ROUGH scetches I made up under Marty's fone instructions.

[Note: I am putting them up here in order to show the evolution of the concept!]

Ultra basic concept.

1st evolution was to double it up.

2nd evolution was to add the rotating axel.

3rd evolution was to show the basic concept of the 2nd evolutions workings.

Hint: Open a new Browser Window and tab these in the following order and then cycle through the tabs from left to right, over and over. [it acts as a poor mans .gif]

V3.a

V3.b

V3.c

V3.d

At this point in the conceptual designs evolution I mentioned to marty that we could get power out of this basic design by adding a dynamo onto the axel and deriving AC power which then can be converted to DC using a basic inverter circuit.

But not everybody is an electrical wizard and so we moved onto evolving the design so that the axel only rotates in one direction regardless of the rest of the machines workings.

Such an evolution will provide direct DC current and although it may be in pulses, that can be compensated for with a capacitor.

Now as for applying heat as pressure and taking into consideration that the nitinol rods need to also be cooled I have been fanatsizing about using compressed air ...which when compressed creates a lot of heat ... and when it is expanded [suddenly] it creates cooling.

Personal Disclosure: IF I am Online on ATS ... anybody with ideas who doesnt want to post them here [its nice to avoid ridicule and being put on a list etc! ] can u2u me with the info and I will assure their anonymity [i.e. I will delete the u2u immediatelty after copying the data ... note you will also have to delete the u2u that is sent for complete anonymity to be fully assured].

edit on 30-6-2012 by OmegaLogos because: Edited to fix spelling.

new topics

-

George Knapp AMA on DI

Area 51 and other Facilities: 3 hours ago -

Not Aliens but a Nazi Occult Inspired and then Science Rendered Design.

Aliens and UFOs: 4 hours ago -

Louisiana Lawmakers Seek to Limit Public Access to Government Records

Political Issues: 6 hours ago -

The Tories may be wiped out after the Election - Serves them Right

Regional Politics: 7 hours ago -

So I saw about 30 UFOs in formation last night.

Aliens and UFOs: 9 hours ago -

Do we live in a simulation similar to The Matrix 1999?

ATS Skunk Works: 10 hours ago -

BREAKING: O’Keefe Media Uncovers who is really running the White House

US Political Madness: 10 hours ago -

Biden--My Uncle Was Eaten By Cannibals

US Political Madness: 11 hours ago -

"We're All Hamas" Heard at Columbia University Protests

Social Issues and Civil Unrest: 11 hours ago

top topics

-

BREAKING: O’Keefe Media Uncovers who is really running the White House

US Political Madness: 10 hours ago, 23 flags -

George Knapp AMA on DI

Area 51 and other Facilities: 3 hours ago, 18 flags -

Biden--My Uncle Was Eaten By Cannibals

US Political Madness: 11 hours ago, 18 flags -

African "Newcomers" Tell NYC They Don't Like the Free Food or Shelter They've Been Given

Social Issues and Civil Unrest: 17 hours ago, 12 flags -

"We're All Hamas" Heard at Columbia University Protests

Social Issues and Civil Unrest: 11 hours ago, 7 flags -

Louisiana Lawmakers Seek to Limit Public Access to Government Records

Political Issues: 6 hours ago, 7 flags -

Russian intelligence officer: explosions at defense factories in the USA and Wales may be sabotage

Weaponry: 16 hours ago, 6 flags -

So I saw about 30 UFOs in formation last night.

Aliens and UFOs: 9 hours ago, 5 flags -

The Tories may be wiped out after the Election - Serves them Right

Regional Politics: 7 hours ago, 3 flags -

Not Aliens but a Nazi Occult Inspired and then Science Rendered Design.

Aliens and UFOs: 4 hours ago, 3 flags

active topics

-

Candidate TRUMP Now Has Crazy Judge JUAN MERCHAN After Him - The Stormy Daniels Hush-Money Case.

Political Conspiracies • 376 • : RazorV66 -

-@TH3WH17ERABB17- -Q- ---TIME TO SHOW THE WORLD--- -Part- --44--

Dissecting Disinformation • 531 • : cherokeetroy -

Biden--My Uncle Was Eaten By Cannibals

US Political Madness • 41 • : Halfswede -

So I saw about 30 UFOs in formation last night.

Aliens and UFOs • 20 • : Halfswede -

MULTIPLE SKYMASTER MESSAGES GOING OUT

World War Three • 33 • : Halfswede -

George Knapp AMA on DI

Area 51 and other Facilities • 12 • : theshadowknows -

Not Aliens but a Nazi Occult Inspired and then Science Rendered Design.

Aliens and UFOs • 7 • : JonnyC555 -

Mood Music Part VI

Music • 3057 • : BatCaveJoe -

The Tories may be wiped out after the Election - Serves them Right

Regional Politics • 19 • : alwaysbeenhere2 -

"We're All Hamas" Heard at Columbia University Protests

Social Issues and Civil Unrest • 125 • : KrustyKrab