It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

5

share:

I'm writing today to bring the attention of ATS'ers to the miracle material nitinol. Nitinol is what's known as a shape memory alloy. Put simply

Nitinol when heated and or cooled can be made to change from whatever shape you have bent or molded it to back to an original shape you have

"trained" it to be in. This means nitinol can change heat or cold differentials directly into mechanical work. While this ability is not unique it

is still a fairly useful ability.

I am currently embarking on a project to design myself a nitinol based energy recovery system for use with waste heat and or solar thermal energy. If I am correct I think Nitinol may be able to be used to design a simple home power generation system at relatively low cost. Or that is the goal at least right now I am in the process of doing primary research and trying to narrow down the design that will be simple enough to design and build at a reasonable price while being high powered enough to run a decent size generator.

This is where you guys come in: I will be putting all my research materials into this thread so you guys can see what i'm seeing and hopefully help me come up with the best idea/design possible.

I'd like to start this off by posting a whole host of relevant links and source material in their order of importance.

This video covers the initial discovery and early motors designed...

ideally I'd like to do something along the lines of a free piston generator type assembly as it would be the simplest and easiest to create multiples of.

this patent shows a motor like I am envisioning but I need help with ideas to make it simpler

This is a much simpler but I feel not quite ideal design we'll call this backup plan 1

This is another refined version of backup plan 1 we'll call this backup plan 2

Proceedings of the nitinol heat engine conference: Tons of information on working engines up to 25 horsepower

Source manual for Nitinol and it's uses

training nitinol google search

Other stuff to consider/TONS of supplemental information for those interested in delving into the subject

This engine design is interesting and might have useful atrributes to include in our design

Missing nitinol motor files tied to roswell?

original nitinol engine designer speaks out

great article and nitinol and nitinol motors tons of information

I am currently embarking on a project to design myself a nitinol based energy recovery system for use with waste heat and or solar thermal energy. If I am correct I think Nitinol may be able to be used to design a simple home power generation system at relatively low cost. Or that is the goal at least right now I am in the process of doing primary research and trying to narrow down the design that will be simple enough to design and build at a reasonable price while being high powered enough to run a decent size generator.

This is where you guys come in: I will be putting all my research materials into this thread so you guys can see what i'm seeing and hopefully help me come up with the best idea/design possible.

I'd like to start this off by posting a whole host of relevant links and source material in their order of importance.

This video covers the initial discovery and early motors designed...

ideally I'd like to do something along the lines of a free piston generator type assembly as it would be the simplest and easiest to create multiples of.

this patent shows a motor like I am envisioning but I need help with ideas to make it simpler

This is a much simpler but I feel not quite ideal design we'll call this backup plan 1

This is another refined version of backup plan 1 we'll call this backup plan 2

Proceedings of the nitinol heat engine conference: Tons of information on working engines up to 25 horsepower

Source manual for Nitinol and it's uses

training nitinol google search

Other stuff to consider/TONS of supplemental information for those interested in delving into the subject

This engine design is interesting and might have useful atrributes to include in our design

Missing nitinol motor files tied to roswell?

original nitinol engine designer speaks out

great article and nitinol and nitinol motors tons of information

I hope you have done your homework as to intellectual property and any following monetary gains...

that is... well, dependent on your aim. Is it for the money, or is it for the greater good?

just wondering, because you didn't address that part...

that is... well, dependent on your aim. Is it for the money, or is it for the greater good?

just wondering, because you didn't address that part...

Most of the patents i am referencing are old enough to have lapsed into public record luckily. The one that hasn't well let's just say that by the

time I finished revamping it for my purposes it would be so altered as to not be recognizable.

In addition to this I am envisioning this idea for entirely personal uses although if I get a working system I'd want to open source it so others can gain from what I've figured out.

So in answer to your question I don't intend to commercialize the technology.

In addition to this I am envisioning this idea for entirely personal uses although if I get a working system I'd want to open source it so others can gain from what I've figured out.

So in answer to your question I don't intend to commercialize the technology.

reply to post by MESSAGEFROMTHESTARS

Explanation: The original patent was in 1965 ...

From wiki ... Nickel titanium [wiki]

Personal Disclosure: Its free to use WITHIN the limits of NEW patents applied for and granted since that time.

Explanation: The original patent was in 1965 ...

From wiki ... Nickel titanium [wiki]

References...

[edit by OL to redact unrequired references]

2: ^ F.E. Wang, W.J. Buehler & S.J. Pickart, "Crystal structure and a unique martensitic transition of TiNi," Journal of Applied Physics 36 (1965) p 3232-3239.

Personal Disclosure: Its free to use WITHIN the limits of NEW patents applied for and granted since that time.

From everything I read...

This has very little potential as being any answer as to energy demands.

It's just an opinion though... based on how much attention this idea has been given, and how little it has been produced. Which screams the following... it's not applicable towards meeting any real energy demands.

Go big or go home, this is not it.

But please, prove this wrong, develope something that may change the world.

I like the idea of solar thermal application, if you were to mix in geothermal... I've always wanted to make rows of lamina flow stirling engines, place them in the ground, and have the part that reaches the surface to supply the heat...

btw... with out reading through everything, what are the temps necessary to get a reaction and to bring it back to its original shape?

This has very little potential as being any answer as to energy demands.

It's just an opinion though... based on how much attention this idea has been given, and how little it has been produced. Which screams the following... it's not applicable towards meeting any real energy demands.

Go big or go home, this is not it.

But please, prove this wrong, develope something that may change the world.

I like the idea of solar thermal application, if you were to mix in geothermal... I've always wanted to make rows of lamina flow stirling engines, place them in the ground, and have the part that reaches the surface to supply the heat...

btw... with out reading through everything, what are the temps necessary to get a reaction and to bring it back to its original shape?

Well that's the interesting part. Depending on the specific alloy you use and the "training" process you use with the material you can make it react

in ranges from -150 celsius to around 26.7 degrees celsius. So There is a huge range of temperatures to work with.

Honestly with everything I've read I've come to the conclusion that my best bet is to shoot for kilowatt level devices and then produce say 5 of them... You are right about it not being an ideal solution for enterprise or grid scale solutions, but that is not what i'm after. I just want to design and build something small and cheap enough to help your average homeowner.

I've also seriously considered using this as a cogeneration method to harness energy off the exhaust from a wood stove or a gasoline motor.

I am still very much in the research phase of this whole project and actively looking for suggestions or etc from anyone willing to help.

Honestly with everything I've read I've come to the conclusion that my best bet is to shoot for kilowatt level devices and then produce say 5 of them... You are right about it not being an ideal solution for enterprise or grid scale solutions, but that is not what i'm after. I just want to design and build something small and cheap enough to help your average homeowner.

I've also seriously considered using this as a cogeneration method to harness energy off the exhaust from a wood stove or a gasoline motor.

I am still very much in the research phase of this whole project and actively looking for suggestions or etc from anyone willing to help.

edit

on 5-5-2012 by roguetechie because: (no reason given)

edit on 5-5-2012 by roguetechie because: making farheinheit into

celsius

Really?

It used to be that a thread like this with someone asking for help and ideas on a subject like this would bring replies fast and furious. I'm not asking you guys to do the project for me... as a matter of fact i have a pretty good idea of what I"m going to do already, but I would particularly enjoy hearing from you guys any wild arsed speculation or down to earth ideas you may have.

Come ON ATS brain trust I'm calling you out here... what are your thoughts, feelings, ideas, or etc on this subject?

I'm slowly working up a drawing in autodesk inventor of the first configuration I want to try and when I get it done I'll post big pictures here in the thread. I've also managed to talk the girlfriend into letting me order parts to experiment with. I"m ordering a big package of k'nex (cheap and easy source of parts for mockups and etc), a dc multi meter, some magnets, 50 feet of 22 gauge nitinol wire, and some miscellaneous stuff to work with. If anyone else has any suggestions let me know and I'll see if I can fit it into the budget.

It used to be that a thread like this with someone asking for help and ideas on a subject like this would bring replies fast and furious. I'm not asking you guys to do the project for me... as a matter of fact i have a pretty good idea of what I"m going to do already, but I would particularly enjoy hearing from you guys any wild arsed speculation or down to earth ideas you may have.

Come ON ATS brain trust I'm calling you out here... what are your thoughts, feelings, ideas, or etc on this subject?

I'm slowly working up a drawing in autodesk inventor of the first configuration I want to try and when I get it done I'll post big pictures here in the thread. I've also managed to talk the girlfriend into letting me order parts to experiment with. I"m ordering a big package of k'nex (cheap and easy source of parts for mockups and etc), a dc multi meter, some magnets, 50 feet of 22 gauge nitinol wire, and some miscellaneous stuff to work with. If anyone else has any suggestions let me know and I'll see if I can fit it into the budget.

Explanation:

Ok here is my idea ...

I call it the stent-vent valve and I believe it could be made with any bimetalic strip ... not just nitinol!

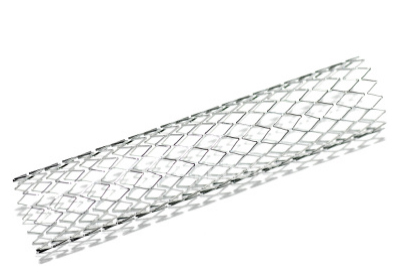

Originally I took the concept of a medical stent ...

I do NOT envisage such complicated design and instead I am working off of a cycinder of collapsed 'garden' lattice.

This cycinder of lattice would act as a closed cylinder whilst remaining below the transition temperature of the pre-trained nitinol wire slat.

The individual nitinol slats in the lattice would 'pop' straight at the transition temperature and would force the lattice to expand ...

The effect here is twofold ...

1stly The nitinol wire slats of the lattice now extert a pressure as they pop the lattice work open and this is where we get the heat energy transformed into a mechanical force.

How that is captured and put to work can be a matter for debate.

2ndly The hot fluid/gas (steam ) pumped into the stentvent, to force it open via both pressure and heat influx which triggers the popping at the trasition temperature, ... is now vented out the open pours of the lattice and this creates both a sudden dropping in internal pressure of the stentvent and a rapid cooling due to that sudden depressurization and the drops the temperature below the pretrained nitinols transition temperature and the stentvent 'relaxes' as it contracts under the cooling and returns to a closed state.

Finally the whole cycle is repeated.

Personal Disclosure: The above is a very rough idea and any errors in logic etc are my own.

Ok here is my idea ...

I call it the stent-vent valve and I believe it could be made with any bimetalic strip ... not just nitinol!

Originally I took the concept of a medical stent ...

I do NOT envisage such complicated design and instead I am working off of a cycinder of collapsed 'garden' lattice.

This cycinder of lattice would act as a closed cylinder whilst remaining below the transition temperature of the pre-trained nitinol wire slat.

The individual nitinol slats in the lattice would 'pop' straight at the transition temperature and would force the lattice to expand ...

The effect here is twofold ...

1stly The nitinol wire slats of the lattice now extert a pressure as they pop the lattice work open and this is where we get the heat energy transformed into a mechanical force.

How that is captured and put to work can be a matter for debate.

2ndly The hot fluid/gas (steam ) pumped into the stentvent, to force it open via both pressure and heat influx which triggers the popping at the trasition temperature, ... is now vented out the open pours of the lattice and this creates both a sudden dropping in internal pressure of the stentvent and a rapid cooling due to that sudden depressurization and the drops the temperature below the pretrained nitinols transition temperature and the stentvent 'relaxes' as it contracts under the cooling and returns to a closed state.

Finally the whole cycle is repeated.

Personal Disclosure: The above is a very rough idea and any errors in logic etc are my own.

The more I ruminate on this project the more I think this should be used as a secondary cogeneration option off of another generation technology... it

just begs to be used to deal with waste heat from another process. While I will still be pursuuing the solar thermal option I will be seeing if I can

find a way to put a heat pump into the loop somehow that I can generate off of.

I can't really articulate what I'm thinking yet but I still remain convinced that this technology has a place and could be very valuable in that niche.

I will close this message by asking once more for any ideas or wild speculation you care to throw my way.... Who knows it might jar an idea loose.

I'm ordering my supply of parts monday and hope to be started working on different iterations by next weekend or the weekend after. Thanks to the few who have supported this thread I hope you will continue to support it as it progresses.

I can't really articulate what I'm thinking yet but I still remain convinced that this technology has a place and could be very valuable in that niche.

I will close this message by asking once more for any ideas or wild speculation you care to throw my way.... Who knows it might jar an idea loose.

I'm ordering my supply of parts monday and hope to be started working on different iterations by next weekend or the weekend after. Thanks to the few who have supported this thread I hope you will continue to support it as it progresses.

Yep, just came across this awesome stuff today. Waste heat capture turn into energy seems the best application, as well as solar heating options.

What large scale production generates lots of waste heat? Brewing possibly, any steam turbine could be augmented with this. It seems like energy production processes could be outfitted with large scale systems to increase their output, and this might address some energy needs and demands.

Very hopeful this will take off like crazy and move the world.

What large scale production generates lots of waste heat? Brewing possibly, any steam turbine could be augmented with this. It seems like energy production processes could be outfitted with large scale systems to increase their output, and this might address some energy needs and demands.

Very hopeful this will take off like crazy and move the world.

While doing my research on nitinol and nitinol motors I ran across the LLoyd Tanner Steam Boiler which uses an amazingly efficient friction based

process to create massive amounts of heat. I have decided to give this idea a go at design and construction. While this doesn't mean I have lost

interest in Nitinol, it does mean that if I use nitinol motors in it's construction they wil be a small part of an overall larger system.

This is as it should be in my eyes since nitinol, while amazing, is not really suited for mainline power generation in the form factors I can get it in at a reasonable price. Once I get a working steam boiler up and running I will be checking for left over waste heat at various stages and if I find useable heat you can bet I'll be adding nitinol motors to these areas. But mainly my friction boiler will depend on a pair of tesla turbines and a tesla pump for power generation.

You can read more about this project at:www.abovetopsecret.com...

I sincerely hope that those of us searching for reasonable means to power our lives and homes can find it in the months and years ahead, and am looking to do everything I can to do my part in making this happen.

This is as it should be in my eyes since nitinol, while amazing, is not really suited for mainline power generation in the form factors I can get it in at a reasonable price. Once I get a working steam boiler up and running I will be checking for left over waste heat at various stages and if I find useable heat you can bet I'll be adding nitinol motors to these areas. But mainly my friction boiler will depend on a pair of tesla turbines and a tesla pump for power generation.

You can read more about this project at:www.abovetopsecret.com...

I sincerely hope that those of us searching for reasonable means to power our lives and homes can find it in the months and years ahead, and am looking to do everything I can to do my part in making this happen.

new topics

-

One Flame Throwing Robot Dog for Christmas Please!

Weaponry: 14 minutes ago -

Don't take advantage of people just because it seems easy it will backfire

Rant: 28 minutes ago -

VirginOfGrand says hello

Introductions: 1 hours ago -

Should Biden Replace Harris With AOC On the 2024 Democrat Ticket?

2024 Elections: 1 hours ago -

University student disciplined after saying veganism is wrong and gender fluidity is stupid

Education and Media: 4 hours ago -

Geddy Lee in Conversation with Alex Lifeson - My Effin’ Life

People: 5 hours ago -

God lived as a Devil Dog.

Short Stories: 5 hours ago -

Police clash with St George’s Day protesters at central London rally

Social Issues and Civil Unrest: 7 hours ago -

TLDR post about ATS and why I love it and hope we all stay together somewhere

General Chit Chat: 8 hours ago -

Hate makes for strange bedfellows

US Political Madness: 10 hours ago

top topics

-

Hate makes for strange bedfellows

US Political Madness: 10 hours ago, 18 flags -

Who guards the guards

US Political Madness: 13 hours ago, 13 flags -

Police clash with St George’s Day protesters at central London rally

Social Issues and Civil Unrest: 7 hours ago, 8 flags -

TLDR post about ATS and why I love it and hope we all stay together somewhere

General Chit Chat: 8 hours ago, 7 flags -

University student disciplined after saying veganism is wrong and gender fluidity is stupid

Education and Media: 4 hours ago, 7 flags -

Should Biden Replace Harris With AOC On the 2024 Democrat Ticket?

2024 Elections: 1 hours ago, 4 flags -

Has Tesla manipulated data logs to cover up auto pilot crash?

Automotive Discussion: 14 hours ago, 2 flags -

Don't take advantage of people just because it seems easy it will backfire

Rant: 28 minutes ago, 2 flags -

Geddy Lee in Conversation with Alex Lifeson - My Effin’ Life

People: 5 hours ago, 2 flags -

God lived as a Devil Dog.

Short Stories: 5 hours ago, 2 flags

active topics

-

Should Biden Replace Harris With AOC On the 2024 Democrat Ticket?

2024 Elections • 22 • : VirginOfGrand -

Don't take advantage of people just because it seems easy it will backfire

Rant • 1 • : worldstarcountry -

Thousands Of Young Ukrainian Men Trying To Flee The Country To Avoid Conscription And The War

Other Current Events • 121 • : NorthOS -

One Flame Throwing Robot Dog for Christmas Please!

Weaponry • 0 • : worldstarcountry -

University student disciplined after saying veganism is wrong and gender fluidity is stupid

Education and Media • 17 • : DBCowboy -

-@TH3WH17ERABB17- -Q- ---TIME TO SHOW THE WORLD--- -Part- --44--

Dissecting Disinformation • 632 • : daskakik -

So I saw about 30 UFOs in formation last night.

Aliens and UFOs • 43 • : DaydreamerX -

"We're All Hamas" Heard at Columbia University Protests

Social Issues and Civil Unrest • 261 • : YourFaceAgain -

Why did Phizer team with nanobot maker

Medical Issues & Conspiracies • 18 • : annonentity -

Geddy Lee in Conversation with Alex Lifeson - My Effin’ Life

People • 4 • : underpass61

5