It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

share:

Originally posted by ANOK

Originally posted by DrEugeneFixer

We know that the columns were pulled inward.

How do you know that, no one could see inside the towers?

Here is a picture of the columns clearly bowing inward, with straight lines helpfully drawn to show their degree of deformation. Some ignorant truthers have claimed that only the aluminum cladding was bowed. This is nonsense. The cladding is securely fastened to the steel columns and spandrels, and can't possibly have moved that far without the steel having moved, for the simple reason that 2 solids can't occupy the same space at the same time! There isn't that much space between the two.

More images Here

Originally posted by ANOKWhy do keep talking about lateral forces? Lateral means from the side, for a straight down collapse the forces are axial.

It's quite simple, my dear chap. In order for any of the debris to have landed outside the footprint of the towers, some lateral force must have been present, to provide horizontal acceleration. For someone who claims to know physics, this should have been elementary!

Now, on to the case under discussion, the bowed columns. We know for certain the columns bowed inward in the region of the impacts and fires, as the image linked above, along with many others, demonstrates. This must have been accomplished by the application of some force. We know that the trusses and slabs, in thier original position would be in the way of any bowing of the columns, so they too must have either broken or sagged.

So either the columns pushed in on the trusses, or the sagging trusses pulled in on the columns. In either case, lateral forces were certainly present.

So that's why I talk about them.

The rest of your post is just confused nonsense.

reply to post by psikeyhackr

I don't want evidence, I just want to know. C'mon son!!!!! What is your take.

I mean, I openly admit I think we shot down 93 and that 587 was covered up by the government. You are yelling about things with no proof but read this post and watch the tool booth videos. Tell me that is not an explosion. Wind shear my arse.

www.abovetopsecret.com...

This is the tip of the discussion on this subject. If you were a major league pitcher no one would ask you if you could throw a curve ball, they would expect it.

There is rarely a conspiracy if it is widely known...it is then just a good story.

I don't want evidence, I just want to know. C'mon son!!!!! What is your take.

I mean, I openly admit I think we shot down 93 and that 587 was covered up by the government. You are yelling about things with no proof but read this post and watch the tool booth videos. Tell me that is not an explosion. Wind shear my arse.

www.abovetopsecret.com...

This is the tip of the discussion on this subject. If you were a major league pitcher no one would ask you if you could throw a curve ball, they would expect it.

There is rarely a conspiracy if it is widely known...it is then just a good story.

Originally posted by esdad71

reply to post by psikeyhackr

I don't want evidence, I just want to know. C'mon son!!!!! What is your take.

I mean, I openly admit I think we shot down 93 and that 587 was covered up by the government. You are yelling about things with no proof but read this post and watch the tool booth videos. Tell me that is not an explosion. Wind shear my arse.

www.abovetopsecret.com...

This is the tip of the discussion on this subject. If you were a major league pitcher no one would ask you if you could throw a curve ball, they would expect it.

There is rarely a conspiracy if it is widely known...it is then just a good story.

I do not know anything about or care about 587.

I am not talking about any conspiracy. I am talking about the core having to be collapsed in order for the north tower to come down in less than 25 seconds and that there being no way for the top to provide the energy to do it. Floor connections outside the core are unimportant. Flight 587 is even less important.

I didn't even know what you were talking about and am not interested.

psik

Originally posted by DrEugeneFixer

Some ignorant truthers have claimed that only the aluminum cladding was bowed. This is nonsense. The cladding is securely fastened to the steel columns and spandrels, and can't possibly have moved that far without the steel having moved, for the simple reason that 2 solids can't occupy the same space at the same time! There isn't that much space between the two.

That is funny. How could the cladding bow inwards without the steel underneath doing it.

psik

Originally posted by psikeyhackr

That is funny. How could the cladding bow inwards without the steel underneath doing it.

psik

Actually it's not funny at all.

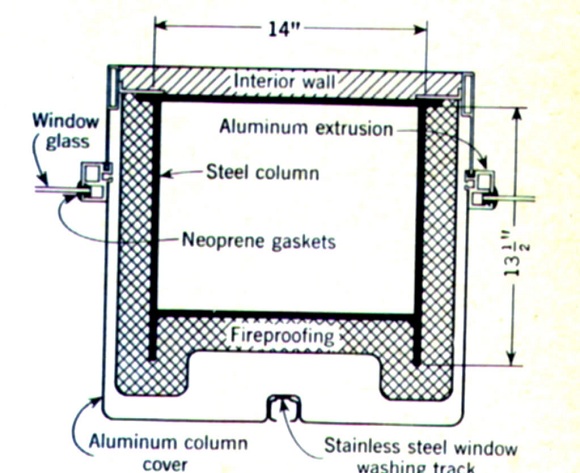

There would have to be a gap between the steel and the aluminum to avoid galvanic corrosion, which would have eaten away the aluminum.

The most logical conclusion is that we simply see the aluminum bowing inwards. Or is sagging trusses a more logical answer?

Galvanic corrosion is due to an electrical contact with a more noble metal or a non-metallic conductor in a conductive environment. The galvanic corrosion is very dependent of the cathode reaction and which metals are in contact which each other...

...The efficiency of this cathodic reaction will determine the corrosion rate. The most common examples of galvanic corrosion of aluminium alloys are when they are joined to steel or copper and exposed to a wet saline environment.

aluminumsurface.blogspot.com...

Aluminum and steel would never be put in direct contact with each other. That is like engineering 101.

You can see it quite clearly in this pic, look at the cladding that is falling off, and the cladding that is not bowed in. If the cladding was directly attached to the steel it would pull all of it in...

edit on 12/22/2011 by ANOK because: typo

Originally posted by ANOK

Originally posted by psikeyhackr

That is funny. How could the cladding bow inwards without the steel underneath doing it.

psik

There would have to be a gap between the steel and the aluminum

There surely would. But only a matter of less than 5 inches at the very outside. Far less than we see the bowing over the distance of several stories.

Which brings up another issue: how could the cladding bow in a continuous curve over the course of several stories, when at a minimum, it has points of attachment at each single story? Surely, it has to bow between points of attachment, does it not? if not, why not?

Originally posted by ANOK

Originally posted by psikeyhackr

That is funny. How could the cladding bow inwards without the steel underneath doing it.

psik

Actually it's not funny at all.

There would have to be a gap between the steel and the aluminum to avoid galvanic corrosion, which would have eaten away the aluminum.

The most logical conclusion is that we simply see the aluminum bowing inwards. Or is sagging trusses a more logical answer?

How could the aluminum bow inwards? It was mounted on the outside of the steel. Wasn't the galvanic corrosion causing the cladding to fall off and that was the problem with the entire building?

psik

Originally posted by psikeyhackr

How could the aluminum bow inwards? It was mounted on the outside of the steel.

There was a gap between the steel and the aluminum. When the aluminum got hot it collapsed/bowed inwards against the steel. I forget what they're called but sometimes they use rubber to isolate the fasteners between the metals to reduce corrosion around the fasteners, anyway they could have melted allowing the cladding to fall against the steel.

Does sagging trusses pulling in the columns make more sense to you, surely not? Or do you have another hypothesis that explains it?

Wasn't the galvanic corrosion causing the cladding to fall off and that was the problem with the entire building

I have not heard of that. What I've seen of the cladding post collapse I see no sign of corrosion, which shows as a white powder on aluminum. If they had put the cladding directly on the steel it would have corroded significantly in the years it was standing. There could have been areas where the cladding was closer to the steel, like at the sides of the wrap around, that possibly started corroding if enough water got trapped in there.

edit on 12/22/2011 by ANOK because: typo

Originally posted by ANOK

Originally posted by psikeyhackr

How could the aluminum bow inwards? It was mounted on the outside of the steel.

Does sagging trusses pulling in the columns make more sense to you, surely not? Or do you have another hypothesis that explains it?

If the floors could sag that much in two hours it should have been possible to test it and verify it in furnaces. But as far as I know they have not tested them without fireproofing and the ones with fireproofing did not fail.

So I do not have an explanation for the inward bowing but until they do the furnace test I do not just accept the sagging floors crap.

When I don't know I admit I don't know. But with something this important why aren't they testing floors without fireproofing? But if they do the test and they don't fail then these people have a problem.

But the bowing might only be involved in collapse initiation. It does not explain how the buildings could come down so fast. I am not looking for explanations of minor stuff while the elephant in the room is not accounted for.

psik

Originally posted by psikeyhackr

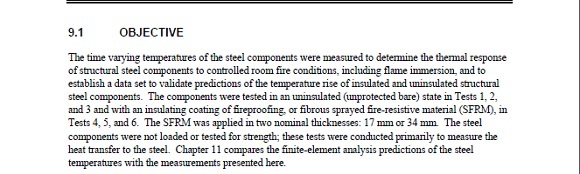

If the floors could sag that much in two hours it should have been possible to test it and verify it in furnaces. But as far as I know they have not tested them without fireproofing and the ones with fireproofing did not fail.

I suggest you read the NIST report before making such claims.

So I do not have an explanation for the inward bowing but until they do the furnace test I do not just accept the sagging floors crap.

Of course you don't. But you'll accept some crap about planted explosives and thermite with no concrete evidence. Way to go.

When I don't know I admit I don't know. But with something this important why aren't they testing floors without fireproofing? But if they do the test and they don't fail then these people have a problem.

They did the test. Read the report.

But the bowing might only be involved in collapse initiation. It does not explain how the buildings could come down so fast. I am not looking for explanations of minor stuff while the elephant in the room is not accounted for.

psik

Oh please. Explosives don't account for the speed either. Explosives didn't pulverize all that steel. It was all there regardless. How do vertical columns stop a collapse once gravity has taken over? Or are saying that the lightweight concrete floors and trusses should've provided the resistance to arrest the collapse?

If the columns had been compromised with thermite at the impact levels ahead of time- then why didn't the airplane impacts initiate the collapse right away? Why did it take an hour or more?

Originally posted by WASTYT

Originally posted by psikeyhackr

If the floors could sag that much in two hours it should have been possible to test it and verify it in furnaces. But as far as I know they have not tested them without fireproofing and the ones with fireproofing did not fail.

I suggest you read the NIST report before making such claims.

Allow me.

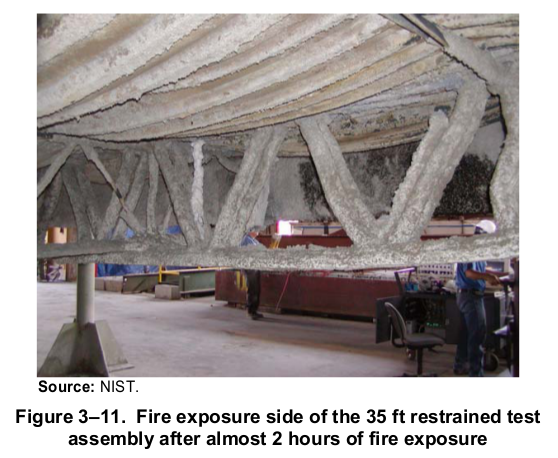

The fire resistance tests showed that the floors were capable of considerable sagging without collapse. The tests also showed fire damage to the bridging trusses and buckling of compression diagonals and the vertical strut near the supports. No evidence of knuckle failures was seen in the tests.

Source: NIST NCSTAR 1-6, Chapter 3, Page 55

NIST certainly doesn't support "controlled demolition".

However, maybe YOU should read the NIST report before making claims.

Originally posted by psikeyhackr

Originally posted by ANOK

Originally posted by psikeyhackr

How could the aluminum bow inwards? It was mounted on the outside of the steel.

Does sagging trusses pulling in the columns make more sense to you, surely not? Or do you have another hypothesis that explains it?

If the floors could sag that much in two hours it should have been possible to test it and verify it in furnaces. But as far as I know they have not tested them without fireproofing and the ones with fireproofing did not fail.

So I do not have an explanation for the inward bowing but until they do the furnace test I do not just accept the sagging floors crap.

When I don't know I admit I don't know. But with something this important why aren't they testing floors without fireproofing? But if they do the test and they don't fail then these people have a problem.

But the bowing might only be involved in collapse initiation. It does not explain how the buildings could come down so fast. I am not looking for explanations of minor stuff while the elephant in the room is not accounted for.

psik

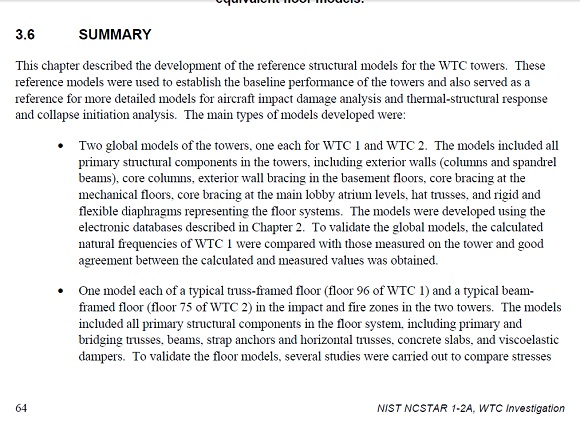

You may want to take a second look at the NIST reports, all of your questions and concerns are addressed in minutia.

Read chapter 9 of the following in regards to the SFRM coating....

Experiments and Modeling of Structural Steel Elements Exposed to Fire. Federal Building and Fire Safety Investigation of the World Trade Center Disaster (NIST NCSTAR 1-5B)

Regarding the floor truss sag and column deflection, start at chapter 3...

Reference Structural Models and Baseline Performance Analysis of the World Trade Center Towers. Federal Building and Fire Safety Investigation of the World Trade Center Disaster (NIST NCSTAR 1-2A)

Hope this helps

reply to post by snowcrash911

The discussion was about sagging trusses, which the previous poster said is not possible. He also said that the NIST didn't perform tests to see if fire could cause sagging to the trusses.

Both those statements are not accurate it seems, which you've so graciously shown. So thank you.

The discussion was about sagging trusses, which the previous poster said is not possible. He also said that the NIST didn't perform tests to see if fire could cause sagging to the trusses.

Both those statements are not accurate it seems, which you've so graciously shown. So thank you.

Originally posted by Drunkenparrot

Hope this helps

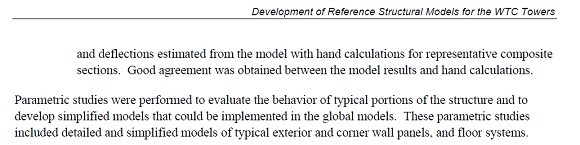

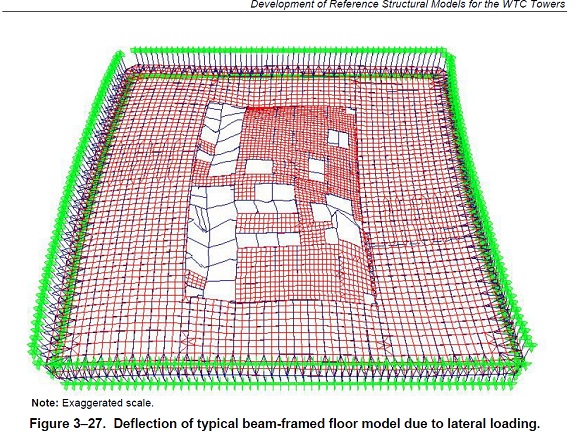

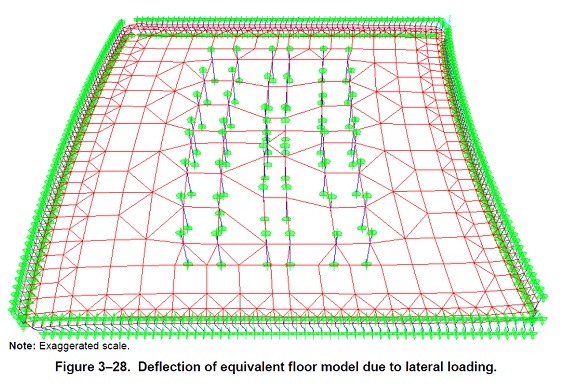

All models are linearly elastic and three-dimensional, and were developed using the Computers and Structures, Inc. SAP2000 Software, Version 8 (SAP2000 2002)

Source: NIST NCSTAR 1-2A, Chapter 3, Page 27

You are citing elements of the NIST report covering computer simulations and preparations for them, not the actual physical experiments with truss floor assembly replicas psik is referring to. You do know the difference between computer simulations and physical experiments? Or were you just posting snapshots from the NIST report which look fancy?

Originally posted by WASTYT

reply to post by snowcrash911

The discussion was about sagging trusses, which the previous poster said is not possible. He also said that the NIST didn't perform tests to see if fire could cause sagging to the trusses.

You didn't read the NIST report, while claiming psik should. The truss floor assemblies were all fireproofed and they did not fail/collapse. Sagging wasn't nearly as extreme as one would expect to cause the perimeter columns to snap due to lateral pull.

That's what I gracefully showed, thank you.

Originally posted by WASTYT

Originally posted by psikeyhackr

If the floors could sag that much in two hours it should have been possible to test it and verify it in furnaces. But as far as I know they have not tested them without fireproofing and the ones with fireproofing did not fail.

I suggest you read the NIST report before making such claims.

I burned the NCSTAR1 report to DVD 4 years ago.

In August of 2004, UL performed tests of WTC floor models, but the floors were barely affected and didn't collapse. Loring Knoblauch resigned suddenly.

In October of 2004, a NIST report update showed contradictions.

In November of 2004 Ryan's letter to Frank Gayle went public, causing UL to quickly backtrack, saying there was "no evidence" that any firm tested the steel, and that they played a "limited" role in the investigation.

911research.wtc7.net...

Because the NIST did not have the necessary facilities, it contracted Underwriter Laboratories to conduct a series of fire endurance tests on trusses like those in the WTC. (The recovered truss samples were too badly deformed during the collapse to test them directly, so NIST fabricated new trusses identical in design.) The purpose of the tests was to establish a baseline, and the results were surprising. Not one of the truss assemblies failed during a series of four tests, not even the truss sprayed with the minimum amount of fireproofing. "The floors continued to support the full design load without collapse for over two hours."[52] The investigative team cautiously noted that the exposure of the floor systems to fire on 9/11 was "substantially different" than the conditions in the test furnaces, which was true enough. Yet, the team noted that "this type of assembly was capable of sustaining a large gravity load without collapsing for a substantial period of time relative to the duration of the fires in any given location on September 11."[53] The UL tests not only laid to rest the theory that the trusses were the cause of the collapse on 9/11, if anything, the tests demonstrated the fundamental soundness of the WTC truss design.

www.rense.com...

You are free to specify what was incorrect about anything I said rather than just make implications.

psik

reply to post by psikeyhackr

THen how did it collapse? We are pages in so # or get off the pot. What was the outside energy source??? That is the point of the OP. I say no, so there is nothing to prove. They came down. End of story.

Spit it out....

THen how did it collapse? We are pages in so # or get off the pot. What was the outside energy source??? That is the point of the OP. I say no, so there is nothing to prove. They came down. End of story.

Spit it out....

Originally posted by snowcrash911

Originally posted by Drunkenparrot

Hope this helps

All models are linearly elastic and three-dimensional, and were developed using the Computers and Structures, Inc. SAP2000 Software, Version 8 (SAP2000 2002)

Source: NIST NCSTAR 1-2A, Chapter 3, Page 27

You are citing elements of the NIST report covering computer simulations and preparations for them, not the actual physical experiments with truss floor assembly replicas psik is referring to. You do know the difference between computer simulations and physical experiments? Or were you just posting snapshots from the NIST report which look fancy?

Are you disputing the accuracy of the data, the methodology or the conclusions provided by the obviously representational computer modeling or just trying to get an easy dig in?

You are also incorrect in your clumsy attempt at glib semantics games with the previous poster WASTYT's reply to psikeyhackr .

The question is whether the truss assemblies failed, not did they collapse as the terms are not mutually exclusive.

In engineering nomenclature, the bowed truss in the posted photo meets the prerequisite criteria and has inarguably failed.This is further borne out on throughout the NIST reports....

...floor component failure leading to sagging (i.e. buckling of truss components..)

...Failure criteria defined the necessary conditions to characterize and quantify the expected failure modes or mechanisms including elastic or plastic buckling, yielding or fracture

Which is exactly what is demonstrated in the photograph of the test model

Originally posted by psikeyhackr

If the floors could sag that much in two hours it should have been possible to test it and verify it in furnaces. But as far as I know they have not tested them without fireproofing and the ones with fireproofing did not fail.

Originally posted by WASTYT

I suggest you read the NIST report before making such claims.

Originally posted by snowcrash911

Allow me.

The fire resistance tests showed that the floors were capable of considerable sagging without collapse. The tests also showed fire damage to the bridging trusses and buckling of compression diagonals and the vertical strut near the supports. No evidence of knuckle failures was seen in the tests.

Source: NIST NCSTAR 1-6, Chapter 3, Page 55

NIST certainly doesn't support "controlled demolition".

However, maybe YOU should read the NIST report before making claims.

I would add the caveat that it is rather pointless to read something if you don't understand what you are reading.

Indeed, who is posting fancy snapshots .....

edit on 23-12-2011 by Drunkenparrot because: Sp

Originally posted by Drunkenparrot

I would add the caveat that it is rather pointless to read something if you don't understand what you are reading.

Indeed, who is posting fancy snapshots .....

I'll make this short and sweet.

All four tests demonstrated that the floor assemblies were capable of sagging without failure.

NIST NCSTAR 1-6, Executive Summary, lxxii

The floor assemblies were capable of sagging without failing, but you weren't capable of failing without nagging.

new topics

-

A man of the people

Diseases and Pandemics: 42 minutes ago -

Ramblings on DNA, blood, and Spirit.

Philosophy and Metaphysics: 1 hours ago -

4 plans of US elites to defeat Russia

New World Order: 2 hours ago -

Thousands Of Young Ukrainian Men Trying To Flee The Country To Avoid Conscription And The War

Other Current Events: 5 hours ago -

12 jurors selected in Trump criminal trial

US Political Madness: 8 hours ago -

Iran launches Retalliation Strike 4.18.24

World War Three: 8 hours ago -

Israeli Missile Strikes in Iran, Explosions in Syria + Iraq

World War Three: 9 hours ago

top topics

-

George Knapp AMA on DI

Area 51 and other Facilities: 15 hours ago, 25 flags -

Israeli Missile Strikes in Iran, Explosions in Syria + Iraq

World War Three: 9 hours ago, 16 flags -

Louisiana Lawmakers Seek to Limit Public Access to Government Records

Political Issues: 17 hours ago, 7 flags -

Iran launches Retalliation Strike 4.18.24

World War Three: 8 hours ago, 6 flags -

Not Aliens but a Nazi Occult Inspired and then Science Rendered Design.

Aliens and UFOs: 15 hours ago, 5 flags -

Thousands Of Young Ukrainian Men Trying To Flee The Country To Avoid Conscription And The War

Other Current Events: 5 hours ago, 4 flags -

12 jurors selected in Trump criminal trial

US Political Madness: 8 hours ago, 4 flags -

4 plans of US elites to defeat Russia

New World Order: 2 hours ago, 2 flags -

Ramblings on DNA, blood, and Spirit.

Philosophy and Metaphysics: 1 hours ago, 1 flags -

A man of the people

Diseases and Pandemics: 42 minutes ago, 0 flags

active topics

-

4 plans of US elites to defeat Russia

New World Order • 10 • : andy06shake -

Elites disapearing

Political Conspiracies • 32 • : SchrodingersRat -

A man of the people

Diseases and Pandemics • 1 • : chr0naut -

Thousands Of Young Ukrainian Men Trying To Flee The Country To Avoid Conscription And The War

Other Current Events • 3 • : Consvoli -

British TV Presenter Refuses To Use Guest's Preferred Pronouns

Education and Media • 67 • : Consvoli -

The Fight for Election Integrity Continues -- Audits, Criminal Investigations, Legislative Reform

2024 Elections • 4138 • : IndieA -

Fossils in Greece Suggest Human Ancestors Evolved in Europe, Not Africa

Origins and Creationism • 63 • : Consvoli -

Mandela Effect - It Happened to Me!

The Gray Area • 112 • : CCoburn -

So I saw about 30 UFOs in formation last night.

Aliens and UFOs • 31 • : Encia22 -

AARO/Dr Kirkpatrick-Caught Lying in UAP report.

Aliens and UFOs • 25 • : Jukiodone