It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

share:

Yes I have seen rebar, but that picture is not detailed enough to tell. Things are not always as they seem or first appear to be.

The fact is it is difficult to tell for certain from the photo, it's purely speculation - not fact.

The fact is it is difficult to tell for certain from the photo, it's purely speculation - not fact.

Plus the notion that electrical wires are as inflexible as solid steel rebar is completely absurd on it's face!

Arrrggghhh well like I said before smith you either need glasses or a better moniter because on my 21" Sony it is perfectly clear what it is.

Electrical conduit that has just been involved in a massive building collapse is probably not even going to be there anymore. It's thin light and very flexible, do you see anything that is obviously conduit? No you don't you are just reaching....

Electrical conduit that has just been involved in a massive building collapse is probably not even going to be there anymore. It's thin light and very flexible, do you see anything that is obviously conduit? No you don't you are just reaching....

I didn't say that, the conversation was about you saying that the appearance of the object in the photo was too rigid to be flexible electrical

conduit. I simply pointed out that the conduit obviously has thick wire in it which would make in inflexible enough to take on that shape.

I never said it made it as strong as or the same as rebar, you're putting words into my mouth.

I never said it made it as strong as or the same as rebar, you're putting words into my mouth.

Originally posted by AgentSmith

I simply pointed out that the conduit obviously has thick wire in it which would make in inflexible enough to take on that shape.

That is far from obvious in fact it is false.

Electrical wire is not as thick and inflexible as rebar.

That notion is ridiculous.

Originally posted by ANOK

Electrical conduit that has just been involved in a massive building collapse is probably not even going to be there anymore. It's thin light and very flexible, do you see anything that is obviously conduit? No you don't you are just reaching....

Good point.

Everything that wasn't steel was completely pulverized to dust.

Everything.

I think our best bet here would be to find diagrams of the WTC floors showing where the electrical would be ran through each floor. I'm fairly

certain that they would be bundled together and ran through the same place (at least between columns), and not spread out and ran in rows like you see

between the core columns in that one image. I've never seen anything like that in a building. And I think I've even seen such images in the

past, showing a typical floor plan and assigning numbers to describe the function of each closed area of the core, air vents, elevators, and all.

This is a great discussion, too. Even though there's disagreement, what's awesome is that we're all thinking critically here. Try to find another board anywhere, where you can have these discussions. It's great.

[edit on 21-5-2006 by bsbray11]

This is a great discussion, too. Even though there's disagreement, what's awesome is that we're all thinking critically here. Try to find another board anywhere, where you can have these discussions. It's great.

[edit on 21-5-2006 by bsbray11]

Originally posted by AgentSmith

I didn't say that, the conversation was about you saying that the appearance of the object in the photo was too rigid to be flexible electrical conduit. I simply pointed out that the conduit obviously has thick wire in it which would make in inflexible enough to take on that shape.

I never said it made it as strong as or the same as rebar, you're putting words into my mouth.

These guys come up with tons of great evidence, which obviously took a lot of time to gather, to support their claim of a concrete core and the best you can come up to argue against it is that electrical conduit can look like rebar. Genius. But the objects in the pictures are obviously not conduit, so why keep dragging this on and on?

To me it seems like a deliberate effort to sidetrack the issue, of which you've done a great job so far. Im a fencesitter on this whole deal, so Im not taking sides really. Just stuck out to me how a few of you fight tooth and nail to close open minds.

I found another pic of it, guys.

Now does that look like electrical conduit?

Now does that look like electrical conduit?

I'm sitting here, in frustration reading this thread, screaming REBAR! over and over. I'm sure there are many others too. I've seen plenty of it

and it's pretty obvious seeing what's going on in this thread. Unbelievable.

Originally posted by AgentSmith

Can you see the ribbing in this electrical conduit?

FWIW, that is BX conduit. I don't know if that type of conduit is allowed in New York city.

The "shinyness" is a non issue since everything was covered with dust, caked on by subsequent rains,

Back to this picture:

I'm surprised none of you have figured this out yet.

Look at that picture again. Is it the corner of the core or the outside corner of the building?

That's right, it's the outside corner of the building. look at the distance between the columns and the orientation of the two corner columns. this is not the core.

Furthermore, based on the fact that there is a slab outside the building footprint, I would guess that those columns were originally below grade.

How does that relate to the core in the high-rise portion?

[edit on 21-5-2006 by HowardRoark]

I'm surprised none of you have figured this out yet.

Look at that picture again. Is it the corner of the core or the outside corner of the building?

That's right, it's the outside corner of the building. look at the distance between the columns and the orientation of the two corner columns. this is not the core.

Furthermore, based on the fact that there is a slab outside the building footprint, I would guess that those columns were originally below grade.

How does that relate to the core in the high-rise portion?

[edit on 21-5-2006 by HowardRoark]

Surely floor plans, construction plans, news articles, trade articles, and more, exist that can lay this issue to rest and end the speculation, i.e.

were the WTC towers' core columns made of rebar-reinforced concrete and steel?

Did some group/agency gather, classify, conceal, or destroy all the telling information, documents, and books regarding the towers' construction and structural components? Surely the firm of architects who designed the towers have all that info in their archives and may be willing to make it public if they have not already done so!

The folks who did the clean-up would be able to tell whether there was rebar everywhere, as there appears to be. What have they said about this?

The items at issue are plainly rebar. There is bent rebar everywhere. Only someone who has never seen rebar up close or never worked with rebar would insist that those items cannot be identified as rebar. Before continuing to insist that these items are conduit rather than rebar, get off your computer chair, go outside, do some field work at a construction site and a demolition site, take some pictures, get some dirt under your clean and tender keyboard hugging fingernails, and report back after you've dirtied your hands.

[edit on 5/21/2006 by dubiousone]

Did some group/agency gather, classify, conceal, or destroy all the telling information, documents, and books regarding the towers' construction and structural components? Surely the firm of architects who designed the towers have all that info in their archives and may be willing to make it public if they have not already done so!

The folks who did the clean-up would be able to tell whether there was rebar everywhere, as there appears to be. What have they said about this?

The items at issue are plainly rebar. There is bent rebar everywhere. Only someone who has never seen rebar up close or never worked with rebar would insist that those items cannot be identified as rebar. Before continuing to insist that these items are conduit rather than rebar, get off your computer chair, go outside, do some field work at a construction site and a demolition site, take some pictures, get some dirt under your clean and tender keyboard hugging fingernails, and report back after you've dirtied your hands.

[edit on 5/21/2006 by dubiousone]

From : wtc.nist.gov...

An actual picture of one of the elevator shaft walls.

You can clearly see the gyp-board planks.

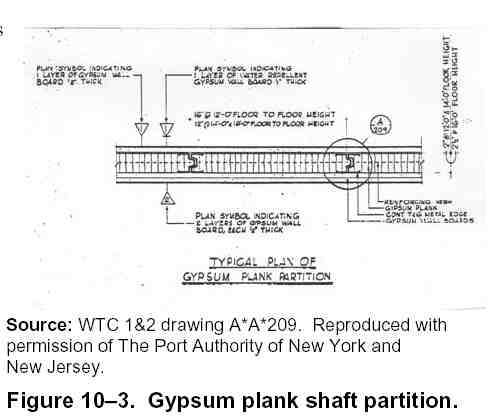

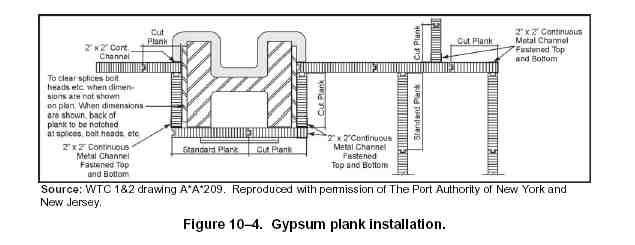

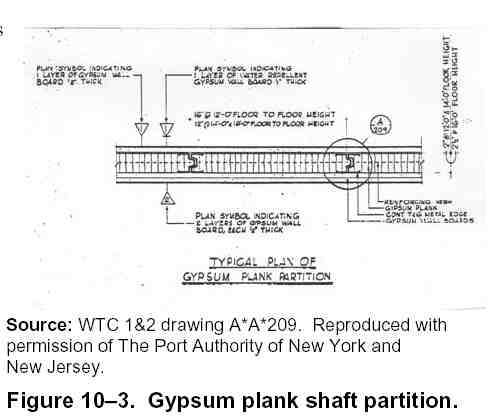

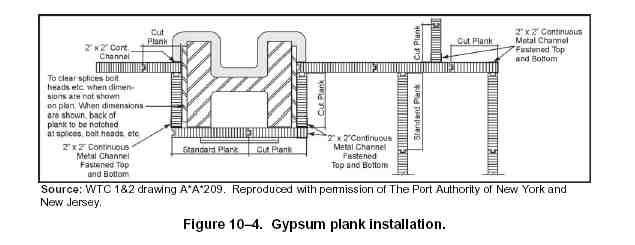

Vertical shafts surrounding stairs, mechanical shafts (carrying supply and return air), elevator hoistways, and utility shafts were all contained within the building core, and were enclosed by gypsum planking similar to fire separations commonly used today in single-family attached housing. While similar to other gypsum shaft wall systems and firewalls, this system was unique and innovative in that it eliminated the need for any framing. The gypsum planks were solid 2 in. thick (2½ in. on floors with 16 ft ceiling heights) and 16 in. wide, with metal tongue or groove channels attached to the long sides that served as wall studs (see Fig. 10–3). Where planks were cut to a narrower width, the cut edge was covered with a 2 in. by 2 in. metal C channel fastened with drywall screws at the top and bottom. Each plank had a mesh layer at its mid thickness and were likely custom fabricated for this job as NIST found no mention of similar products in gypsum industry literature of the time or since. Planks were provided in 12 ft, 14 ft, and 16 ft lengths to run full height. The planks were placed into metal L channels at the bottom and into metal top channels of various shapes depending on the construction element with which it needed to interface

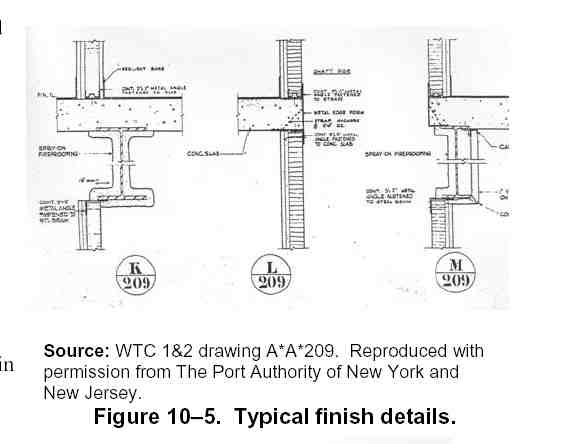

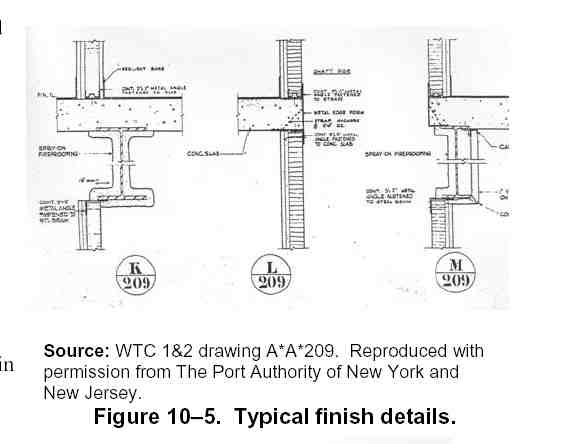

A large number of detail drawings were provided for attaching the planks to various ceiling

constructions (A*A* 209 through A*A*212, see Fig. 10–5). Finish layers were either one or two layers of ½ in. gypsum board (moisture resistant was specified in some locations). Two layers on one side were specified in locations where the other side was a shaft or other unoccupied space, and two layers on one side with a single layer on the other was specified where both sides were in occupied spaces. The required number of layers was indicated on construction drawings (e.g., A*A*20, A*A* 50) by the numbers 1 or 2 in triangles (see Fig. 10–6).

An actual picture of one of the elevator shaft walls.

You can clearly see the gyp-board planks.

The image below shows the 2 type cuts in the steel found at ground zero. Explosive shear on left, torch cut on right.

The first time I saw one of those square cut columns I got a weird feeling. After seeing the below I realized that the square cut columns were only part of the mystery. The other part is that the interior box columns were sheared on level lines!!!!! Green arrow indicates a row of interior box columns and yellow are various support structure for elevator landings, and mechanical equipment inside the core. Note the support structures inside the core are not square cut. The core was to the right of the interior box columns on left, and left of row on right. It detonated leaving only the interior box columns.

About a year ago I realized that near the end of the documentary a set of plates were mentioned that were located where the floor panels joined with the interior box columns. the videographers had been trying to piece together the exact assembly method, parts etc, for the floors. They had reels of 16mm and thousands of stills but not quite enough data to get the full picture. From some sub contactor providing parts they found a detail of the plates that surrounded the columns at each floor/column intersection. They were astounded to find that the plates were spec'd with tolerences of like 0.035 inches clearance from the finished columns. The videographers were experienced in construction and went to the PA and asked about the precision as related to the cost to the public. They were definitely trying to show the public where the money went. The PA was actually upset momentarily that the videographers had went around them to a contractor and gotten information the PA considered sensitive at the time of construction. When pressed for why the tolerences were so tight the PA said that the plates were intended to "index the columns to the floors more perfectly". There were reasons the narrative put forth to question this and the expense, then the matter was left alone.

About a year ago I made this graphic to describe what I had remembered as it could relate to a method to create explosive shear of the columns. An extreme cutting charge built into the floors. The perspective is looking at the core face, or the steel in front of it.

After a year I added a second plate because with only one plate, 1 edge of 2, from the cut edges remaining, would be very ragged. In a year of looking at column ends I never found one. Both edges were clean, square cut tempered steel. So I added a plate that sandwiches C4 and is cast in concrete, around the column. The containment and resulting collapsing plane of high pressure gasses would leave a cut exactly like we see. Examine the edge left by modern LS charges and you'll see the column end above is very similar.

[edit on 21-5-2006 by Christophera]

[edit on 21-5-2006 by Christophera]

The first time I saw one of those square cut columns I got a weird feeling. After seeing the below I realized that the square cut columns were only part of the mystery. The other part is that the interior box columns were sheared on level lines!!!!! Green arrow indicates a row of interior box columns and yellow are various support structure for elevator landings, and mechanical equipment inside the core. Note the support structures inside the core are not square cut. The core was to the right of the interior box columns on left, and left of row on right. It detonated leaving only the interior box columns.

About a year ago I realized that near the end of the documentary a set of plates were mentioned that were located where the floor panels joined with the interior box columns. the videographers had been trying to piece together the exact assembly method, parts etc, for the floors. They had reels of 16mm and thousands of stills but not quite enough data to get the full picture. From some sub contactor providing parts they found a detail of the plates that surrounded the columns at each floor/column intersection. They were astounded to find that the plates were spec'd with tolerences of like 0.035 inches clearance from the finished columns. The videographers were experienced in construction and went to the PA and asked about the precision as related to the cost to the public. They were definitely trying to show the public where the money went. The PA was actually upset momentarily that the videographers had went around them to a contractor and gotten information the PA considered sensitive at the time of construction. When pressed for why the tolerences were so tight the PA said that the plates were intended to "index the columns to the floors more perfectly". There were reasons the narrative put forth to question this and the expense, then the matter was left alone.

About a year ago I made this graphic to describe what I had remembered as it could relate to a method to create explosive shear of the columns. An extreme cutting charge built into the floors. The perspective is looking at the core face, or the steel in front of it.

After a year I added a second plate because with only one plate, 1 edge of 2, from the cut edges remaining, would be very ragged. In a year of looking at column ends I never found one. Both edges were clean, square cut tempered steel. So I added a plate that sandwiches C4 and is cast in concrete, around the column. The containment and resulting collapsing plane of high pressure gasses would leave a cut exactly like we see. Examine the edge left by modern LS charges and you'll see the column end above is very similar.

[edit on 21-5-2006 by Christophera]

[edit on 21-5-2006 by Christophera]

Originally posted by AgentSmith

I love these images:

Beautifull picture AS.

That reall shows those buildings that would ventilate so well in a fire, when that happens the heat goes away. Also it shows the portions that are stronger than the others, these I do believe are the reason why the explosive squibs in only a few areas of the buildings. I always figured they used mostly thermite a large set of explosives at the base and extra explosives in the floors that have extra structure.

Originally posted by HowardRoark

You can clearly see the gyp-board planks.

Why is it gypsum they used Howard? I am sure you know. Put that stuff on a concrete and steel wall and you have firewall that works really well. Of course they are going to use gypsum, its great for fire barrier, better than drywall.

Look at that nice silhouette picture agent smitty put up there, open one side of that building and she becomes the ultimate heat-sink and will ventilate and cool quite considerably. When you see that blacksmoke in the video footage it means it is burning cool bubba before either building fell.

First thing we do on a high rise fire is hook a couple of pumpers up to the fire dept. hook ups. We then blast the sprinkler system with about 200 psi or more of water through as many 4 and a half inch inlets as the building has. Sprinkler heads go off from heat in a only the area they get about 150 degrees. This means the area of fire its very consentrated.

Any idea what 4-5 class A pumpers can squirt through some sprinkler heads? Just one sprinkler will knock you down.

You dont heat a local area of a building tht size to the point of failure. To much heat get drawn awy to the rest of the concrete and steel. The darn thing had heat ventilation before the F.D. even got there. Thats the best remedy we can do when we get onscene is ventilate the heat. That baby had some seriuos ventilation at 80 floors!! Nice and cool...

Heck after that fuel burned off I bet that sucker was just about to put itself out. In fact Battalion 7 said they needed just 2 lines to put it out. Most high rise fires need a few of whats called a master nozzle that is so powerfull they cannot be held by hand, it has to be mounted to something, like a ladder truck. Then you have a small army attacking it with 2 1/2 inch and 1 1/2 inch hoselines. When we say we need a hoseline, that always means 1 1/2 inch. We need to specifiy a 2 1/2. A friggin high rise fire that can be handled with 2 (1 1/2 inch) hoselines is not very hot, or big.

Something was really badly wrong on 9/11 Howard, and you know better.

[edit on 21-5-2006 by LoneGunMan]

Originally posted by LoneGunMan

Originally posted by HowardRoark

You can clearly see the gyp-board planks.

Why is it gypsum they used Howard? I am sure you know. Put that stuff on a concrete and steel wall and you have firewall that works really well. Of course they are going to use gypsum, its great for fire barrier, better than drywall.

Look at that nice silhouette picture agent smitty put up there, open one side of that building and she becomes the ultimate heat-sink and will ventilate and cool quite considerably. When you see that blacksmoke in the video footage it means it is burning cool bubba before either building fell.

Something was really badly wrong on 9/11 Howard, and you know better.

Lonegun,

Good to see a knowlegble person commenting on the non issue of fires.

Let me point out a few things about the towers and their tendencies to draft.

The silhouette images are somewhat deceptive as to how air will travel through them.

The floors had no free flowing passages between floors except through the core. Elevator shafts will draft well if doors at top and bottom are open and all the windows on the upper floor with open shaft doors open are opened/removed. Stair doors (3 per floor) have limited volume flow so won't move much air.

On WCT 1 I saw some windows were busted out on an adjacent face a few floors over the impact floor, so somebody trapped above was probably doing exactly what you suggest over zone of 4-5 floors to vent the smoke and make conditions for those over impact in the core better. The right engine went clean throught the concrete core and slammed against the inside of the opposite side perimeter walls. Fuel from the plane went down the cores elevator shafts in pretty good quantity with a certain mount of debris. Vapors built up and detonated sending a fuel blast out some open doors from elevator shafts on lower floors. The entire core was smoked out bad with small fires at various levels that burnt upward into the core.

Basically the heat applied to steel in the tower had no consequence whatsoever, just as you say. I have a hard time believing that more than a few floor beams were heated to a point where some strength was lost. The trussed floors sagged in that area and that is about all the structural damage from fire I saw. Certainly a few interior box columns outside the concrete core walls got hot, but they were probably 1 inch thick at that height and if more than 25 % of any column on any floor got hot enough to bend I'd be shocked. Of course 25% is not enough for the whole column to bend.

[edit on 21-5-2006 by Christophera]

I'm not an engineer but I'll lend my memory to this

(for what it's worth) ...

It's been a very long time .. but years and years ago I was in the

World Trade Center and took the tour to the top. The one big

image that stuck in my head was the elevator banks. And I seem

to remember they were in the middle of the building.

If my memory is correct and the elevator banks (tons and tons

of elevators) were in the middle ... then there couldn't be a

hard solid concrete core.

I could have a fuzzy memory on this as to where they were,

but I remember them to be in the center of the building.

(for what it's worth) ...

It's been a very long time .. but years and years ago I was in the

World Trade Center and took the tour to the top. The one big

image that stuck in my head was the elevator banks. And I seem

to remember they were in the middle of the building.

If my memory is correct and the elevator banks (tons and tons

of elevators) were in the middle ... then there couldn't be a

hard solid concrete core.

I could have a fuzzy memory on this as to where they were,

but I remember them to be in the center of the building.

Thanks for your input Flyer but nobody is asserting it was a "solid" concrete core.

We know the core housed elevators and stairwells.

Maybe you should read the article we are discussing first before commenting....

concretecore.741.com...

We know the core housed elevators and stairwells.

Maybe you should read the article we are discussing first before commenting....

concretecore.741.com...

new topics

-

Las Vegas UFO Spotting Teen Traumatized by Demon Creature in Backyard

Aliens and UFOs: 1 hours ago -

2024 Pigeon Forge Rod Run - On the Strip (Video made for you)

Automotive Discussion: 2 hours ago -

Gaza Terrorists Attack US Humanitarian Pier During Construction

Middle East Issues: 2 hours ago -

The functionality of boldening and italics is clunky and no post char limit warning?

ATS Freshman's Forum: 3 hours ago -

Meadows, Giuliani Among 11 Indicted in Arizona in Latest 2020 Election Subversion Case

Mainstream News: 4 hours ago -

Massachusetts Drag Queen Leads Young Kids in Free Palestine Chant

Social Issues and Civil Unrest: 4 hours ago -

Weinstein's conviction overturned

Mainstream News: 6 hours ago -

Supreme Court Oral Arguments 4.25.2024 - Are PRESIDENTS IMMUNE From Later Being Prosecuted.

Above Politics: 7 hours ago -

Krystalnacht on today's most elite Universities?

Social Issues and Civil Unrest: 7 hours ago -

Chris Christie Wishes Death Upon Trump and Ramaswamy

Politicians & People: 8 hours ago

top topics

-

Krystalnacht on today's most elite Universities?

Social Issues and Civil Unrest: 7 hours ago, 9 flags -

Weinstein's conviction overturned

Mainstream News: 6 hours ago, 6 flags -

University of Texas Instantly Shuts Down Anti Israel Protests

Education and Media: 10 hours ago, 6 flags -

Supreme Court Oral Arguments 4.25.2024 - Are PRESIDENTS IMMUNE From Later Being Prosecuted.

Above Politics: 7 hours ago, 5 flags -

Massachusetts Drag Queen Leads Young Kids in Free Palestine Chant

Social Issues and Civil Unrest: 4 hours ago, 4 flags -

Meadows, Giuliani Among 11 Indicted in Arizona in Latest 2020 Election Subversion Case

Mainstream News: 4 hours ago, 4 flags -

Chris Christie Wishes Death Upon Trump and Ramaswamy

Politicians & People: 8 hours ago, 2 flags -

Any one suspicious of fever promotions events, major investor Goldman Sachs card only.

The Gray Area: 12 hours ago, 2 flags -

Gaza Terrorists Attack US Humanitarian Pier During Construction

Middle East Issues: 2 hours ago, 2 flags -

2024 Pigeon Forge Rod Run - On the Strip (Video made for you)

Automotive Discussion: 2 hours ago, 1 flags

active topics

-

Candidate TRUMP Now Has Crazy Judge JUAN MERCHAN After Him - The Stormy Daniels Hush-Money Case.

Political Conspiracies • 790 • : Oldcarpy2 -

University of Texas Instantly Shuts Down Anti Israel Protests

Education and Media • 195 • : CriticalStinker -

Supreme Court Oral Arguments 4.25.2024 - Are PRESIDENTS IMMUNE From Later Being Prosecuted.

Above Politics • 70 • : Annee -

Weinstein's conviction overturned

Mainstream News • 20 • : Xtrozero -

Cats Used as Live Bait to Train Ferocious Pitbulls in Illegal NYC Dogfighting

Social Issues and Civil Unrest • 22 • : NoviceStoic4 -

Sunak spinning the sickness figures

Other Current Events • 22 • : angelchemuel -

Massachusetts Drag Queen Leads Young Kids in Free Palestine Chant

Social Issues and Civil Unrest • 10 • : Cre8chaos79 -

Nearly 70% Of Americans Want Talks To End War In Ukraine

Political Issues • 93 • : Xtrozero -

Fossils in Greece Suggest Human Ancestors Evolved in Europe, Not Africa

Origins and Creationism • 88 • : Xtrozero -

Gaza Terrorists Attack US Humanitarian Pier During Construction

Middle East Issues • 20 • : Justsomeboreddude3