It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

share:

What is your opinion on the Petrie granite core which was recently examined by C Dunn? He was allowed to take a moulding of it . The geometry of the

striations do seem to show a spiral cut in one go. What does this tell you about tooling, tool sharpness, rigidity of the set-up used to cut it , and

also downforce on the tool to achieve this?

Thought I’d ask you as Harte won’t address any sticky points, just likes to demand his adversary offer him full and final proofs of their viewpoint , without offering his own. Accuses those who oppose of him of exactly the same thing he does.

But you two can buddy up all you like, the fact that you are both sceptical at the outset destroys your ability and credibility to be balanced and open to new ideas.

Im just a guy who says “ hey, I know what these are as I see them all the time , each one is made by a different tool, wanna know how?”

I would rather listen to a machinist or engineer tell me about tooling than an archaeologist who isn’t a machinist or engineer.

I would rather listen to an Egyptologist regarding dynasties, kings and queens , heiroglyphs , culture than a machinist or engineer.

Pretty simple really. a reply to: Hanslune

Thought I’d ask you as Harte won’t address any sticky points, just likes to demand his adversary offer him full and final proofs of their viewpoint , without offering his own. Accuses those who oppose of him of exactly the same thing he does.

But you two can buddy up all you like, the fact that you are both sceptical at the outset destroys your ability and credibility to be balanced and open to new ideas.

Im just a guy who says “ hey, I know what these are as I see them all the time , each one is made by a different tool, wanna know how?”

I would rather listen to a machinist or engineer tell me about tooling than an archaeologist who isn’t a machinist or engineer.

I would rather listen to an Egyptologist regarding dynasties, kings and queens , heiroglyphs , culture than a machinist or engineer.

Pretty simple really. a reply to: Hanslune

originally posted by: bluesfreak

Deleted

Sorry you're too whiny, trying to hard to be difficult and just not worth talking too

Bye

Whiny? If re-butting dogmatic ideas that don’t match forensic evidence is called that then I stand accused.

You pair are a joke. If my questions on engineering are too difficult for you I suggest you do some reading first. Try a book called “The Machinists Handbook” - standard reading for us. Might give you an insight into a) how things get made b) other ways the same thing can be made.

I answered both you and Harte’s questions, gave you other examples , and asked you questions in return that you both never really answer satisfactorily.

Deny Ignorance?

You pair have never looked so stupid when faced with tough questions on fabrication, differing techniques and possibilities regarding forensics.

Now we all know both your ‘ceiling’ when it comes down to concepts of how things are made .

Get back to the sand, dust and papyrus’ —us engineers and fabricators will work it out for you using the tool marks that you don’t understand, or don’t want to understand.

a reply to: Hanslune

You pair are a joke. If my questions on engineering are too difficult for you I suggest you do some reading first. Try a book called “The Machinists Handbook” - standard reading for us. Might give you an insight into a) how things get made b) other ways the same thing can be made.

I answered both you and Harte’s questions, gave you other examples , and asked you questions in return that you both never really answer satisfactorily.

Deny Ignorance?

You pair have never looked so stupid when faced with tough questions on fabrication, differing techniques and possibilities regarding forensics.

Now we all know both your ‘ceiling’ when it comes down to concepts of how things are made .

Get back to the sand, dust and papyrus’ —us engineers and fabricators will work it out for you using the tool marks that you don’t understand, or don’t want to understand.

a reply to: Hanslune

a reply to: Hanslune

That's the pot calling calling the kettle black...hans you've been whiny for 15yrs...look at your post history.

you and harte are like 2 wandering Mormons pushing your dogmatic assertions....and if one does not agree with your assertions then the personal insults are delivered....

you and your mate seem to be against anything that's not sanctioned by orthodoxy ......

Orthodoxy and insults is all the H team are capable of....

why the hell are you preaching your stuff on a conspiratorial website where people are basically not interested in the orthodox point of view?

I think that you and you mate are flogging a dead horse...

That's the pot calling calling the kettle black...hans you've been whiny for 15yrs...look at your post history.

you and harte are like 2 wandering Mormons pushing your dogmatic assertions....and if one does not agree with your assertions then the personal insults are delivered....

you and your mate seem to be against anything that's not sanctioned by orthodoxy ......

Orthodoxy and insults is all the H team are capable of....

why the hell are you preaching your stuff on a conspiratorial website where people are basically not interested in the orthodox point of view?

I think that you and you mate are flogging a dead horse...

edit on 28-11-2019 by tri-lobe-1 because: spelling

originally posted by: bluesfreak

a reply to: Harte

As I stated previously, I have gone deeply into why you (and others) act this way in hundreds of previous posts. If you wish, i could expound on that aspect of your flawed personality once again.

Pretty funny. The thing is, when we were talking about lathes regarding bowl turning, there is a specific reason why a lathe fits in with the execution of some of them.

If I have to explain to you again for the ‘nth time, as you don’t seem to understand , even though you claim to have used one:

A turning workpiece produces circular striations related to the centre of the piece. It also allows the easy cutting of CURVES inside ( like a bowl ) . Not achievable with a vertical drill. How many times do I have to explain to you how a lathe works when you claim to have used them???!!!!

For the record , the bowls with handles aren’t turned on a lathe as it would smash the handles off, so don’t lump me in there .

Internal work, curved work, work with circular striations related to a centre point is what I’m talking about. Like the strange ringed ‘plate’ I replicated for you .

You appear to disregard tooling forensics, that’s your personality disorder. It’s because you don’t know what they are though, so maybe not your fault .

Whatever.

Read here - chapter five of one of Stock's books.

Includes drawings made by copying various AE artworks that explicitly show how these vessels were made, and ends with a similar vessel made by Stocks - using the same method.

I'd point out that, although Stocks doesn't have 10 or 20 years experience making these vessels (like the AE craftsmen would have had,) he nevertheless creates a reasonable facsimile of the ancient vessels that have been found.

Obviously, you're not going to read this. It is another one of those things you prefer to think doesn't exist.

But maybe some others will, and realize how utterly vapid and empty your stupid claims are.

Harte

a reply to: Harte

Whatever. Read here - chapter five of one of Stock's books. Includes drawings made by copying various AE artworks that explicitly show how these vessels were made, and ends with a similar vessel made by Stocks - using the same method. I'd point out that, although Stocks doesn't have 10 or 20 years experience making these vessels (like the AE craftsmen would have had,) he nevertheless creates a reasonable facsimile of the ancient vessels that have been found. Obviously, you're not going to read this. It is another one of those things you prefer to think doesn't exist. But maybe some others will, and realize how utterly vapid and empty your stupid claims are. Harte

It’s amazing how you get away with not really responding to points made , just firing back new questions ! Great debating technique Harte clap clap.

As I stated above , the bowls with handles are not lathe made as the handles would be smashed off during turning. I never stated they were lathe made .

I haven’t seen Stocks replicate a granite bowl, only softer stone. Stocks research is to be commended, no doubt, but does have flaws .

I was talking about different methods of production.

Here is the object that shows lathe methodology.

This was not made using a stick with a sharp stone tied into it. The tools used here were smaller, more accurate.

The concentricity is magnetic to the eye , shows a centre point , circular striations , lathe finesse all relating to the centre point of the piece .

This piece I do not believe was created vertically as you claim.

So many variables for failure:

Not centring each ring accurately - almost impossible to do by eye . It never works believe me. Centres have to be dead on to produce work like this.

Downforce required may crack piece

Downforce may crack/break the ‘walled’ rings as the work progresses. Or even straight away.

I believe this piece was turned .

Every action on this object can be achieved on a simple lathe. Every one. With accuracy relating to the centre point as a given. AND it would chew through the material in a completely different way than vertical drilling, as the object turns, allowing for the finesse we see, curving, bowling, undercutting, flat surfaces and the ability to place a concentric ring wherever you please with ease.

Still waiting for you to address the other points I suggest regarding mass production techniques such as the cladding on GP and BP that I point out.

Still waiting for your response on large cutters/circular saws and the creation of RESULTANT edging seen on many squared artifacts not just in AE but South America .

The moulding of the Petrie core that does appear to show a consistent spiral cut

Maybe just start with the basics of Resultant edges for me , if the other points are too annoying for you?

I’ll find a link for The Machinists Handbook for you Harte, blow those machine shop cobwebs away, eh?

edit on 29-11-2019 by bluesfreak

because: (no reason given)

You propose that they had some sort of lathes, but never, ever reproduced one in any artwork, whereas they DID reproduce both kinds of saws AND the

upright grinding I'm talking about. Lathes are so much more advanced than either of these other two cutting tools, and I suppose the AE's were too

humble to brag about that?

I told you before, there is nothing at all on that piece that cannot be done with tube saws and grinding.

The concentricity is the only thing I find impressive in the piece, and that can be accomplished with proper fixturing and

jigs. Admittedly, neither of those things is shown in any artwork either.

Harte

I told you before, there is nothing at all on that piece that cannot be done with tube saws and grinding.

The concentricity is the only thing I find impressive in the piece, and that can be accomplished with proper fixturing and

jigs. Admittedly, neither of those things is shown in any artwork either.

Harte

a reply to: Harte

You propose that they had some sort of lathes, but never, ever reproduced one in any artwork, whereas they DID reproduce both kinds of saws AND the upright grinding I'm talking about. Lathes are so much more advanced than either of these other two cutting tools, and I suppose the AE's were too humble to brag about that? I told you before, there is nothing at all on that piece that cannot be done with tube saws and grinding. The concentricity is the only thing I find impressive in the piece, and that can be accomplished with proper fixturing and jigs. Admittedly, neither of those things is shown in any artwork either. Harte

I know they used saws, grinding, little bow driven drills ( shows an understanding of the concept of rotational cutting, which leads on to other forms)

never have disputed it, they drew it.

The AE never showed in any drawings or stelae how they :

Lifted huge blocks from the bedrock of quarries

Built the pyramids

Prepared the site for building pyramids

Carved symmetrically perfect statue busts of Ramses in granite

Raised 90+ tonne granite blocks to the centre of GP and put them in place without breaking them.

Had the means to lift a 1000 tonne plus obelisk from the quarry, which they were surely intending to do.

Maybe too humble to brag about those incredible achievements too.

So much is still surmised and taken as given as to how they they accomplished just those few things that I could think of above .

Many of the AE bowls with handles of the type stocks had a crack at are not ‘true’ in a circular sense when you look at them. They are indeed beautiful pieces, but you can see inconsistencies in the hole at the top, the rims. They are circular ‘enough’ but not lathe circular.

The piece shown has a striking immediacy about how it’s circular features were created. I recognise it because with experience and time in a workshop you get your ‘eye’ in.

That piece sticks out like a sore thumb as we say here.

When I talk about lathes I’m not envisioning something I work on- engineering lathes .

And no, no crystal powered superconducting magnet AE motors either.

The torque required for basic hand powered lathes is achievable .

Making a spindle and even a rope-based chuck system is not beyond them.

You know, in my world, we have all sorts of speeds we use for different materials.

If you exclude the modern generation of 60 horsepower cnc milling machines and similar cnc lathes that turn at incredible speeds , most of the day to day cutting speeds are derived from probably around post WW2 times, maybe the 1950’s. They are still used today because they are efficient.

For example , you can turn hard steel quite easily at 300 rpm. Could go down to 200. Depends on size of workpiece too.

You could do it on any lathe at that speed, including belt driven lathes. All you need is a nice shape of cutting tool that will ‘hook’ into the material and you’re away. 300 rpm is perfectly achievable as a hand cranked speed

Still waiting for your thoughts on the Petrie core moulding , resultant edging ( this includes large disc cutting I suppose too) and repeatability of the bent pyramid casing stones .

Simple lathe, with turninga reply to: Harte

I think an AE version would have simpler Chuck with no need really to remove the piece to do the other side; could start with the bowl face, move to exterior bowl shape and face-off (chop off) the piece at its base, would all stay on one centre then.

but hey, the guy did it out of wood, made a wooden framed lathe ,not very fast rpm , and the wood frame withstood the considerable forces generated when turning .

Interesting eh?

I think an AE version would have simpler Chuck with no need really to remove the piece to do the other side; could start with the bowl face, move to exterior bowl shape and face-off (chop off) the piece at its base, would all stay on one centre then.

but hey, the guy did it out of wood, made a wooden framed lathe ,not very fast rpm , and the wood frame withstood the considerable forces generated when turning .

Interesting eh?

edit on 29-11-2019 by bluesfreak because: (no reason given)

Yes, it's cool.

But the AE's had nothing but sand to cut granite with. Don't see how you put that on a lathe cutting tool.

The scenes Stocks provides are of an artisanal stone worker's workshop, yet they only include the use of saws, pounders (pecking stones), rubbing stones and the upright grinders. Not the sort of place you would expect to see how they hauled heavy stone, though that IS depicted elsewhere, using ropes and sledges.

Forked sticks used in the artwork is what Stocks duplicated. If they had lathes, why would they use that forked stick grinder at all? You obviously know that not ALL AE vessels had handles, and even if they did, that wouldn't prevent them from cutting out the interior of the vessel with a lathe. Nor would the handles prevent them from cutting the exterior with a lathe and leaving a blank at the top for a craftsman to cut the two handles out of.

Makes no sense. Has to make some kind of sense or it's just daydreaming.

Harte

Besides, who would they brag to about that? Everyone in the area would have witnessed how a pyramid was built, but few went into these workshops.

Harte

Harte

But the AE's had nothing but sand to cut granite with. Don't see how you put that on a lathe cutting tool.

The scenes Stocks provides are of an artisanal stone worker's workshop, yet they only include the use of saws, pounders (pecking stones), rubbing stones and the upright grinders. Not the sort of place you would expect to see how they hauled heavy stone, though that IS depicted elsewhere, using ropes and sledges.

Forked sticks used in the artwork is what Stocks duplicated. If they had lathes, why would they use that forked stick grinder at all? You obviously know that not ALL AE vessels had handles, and even if they did, that wouldn't prevent them from cutting out the interior of the vessel with a lathe. Nor would the handles prevent them from cutting the exterior with a lathe and leaving a blank at the top for a craftsman to cut the two handles out of.

Makes no sense. Has to make some kind of sense or it's just daydreaming.

Harte

Besides, who would they brag to about that? Everyone in the area would have witnessed how a pyramid was built, but few went into these workshops.

Harte

Harte

a reply to: LedermanStudio

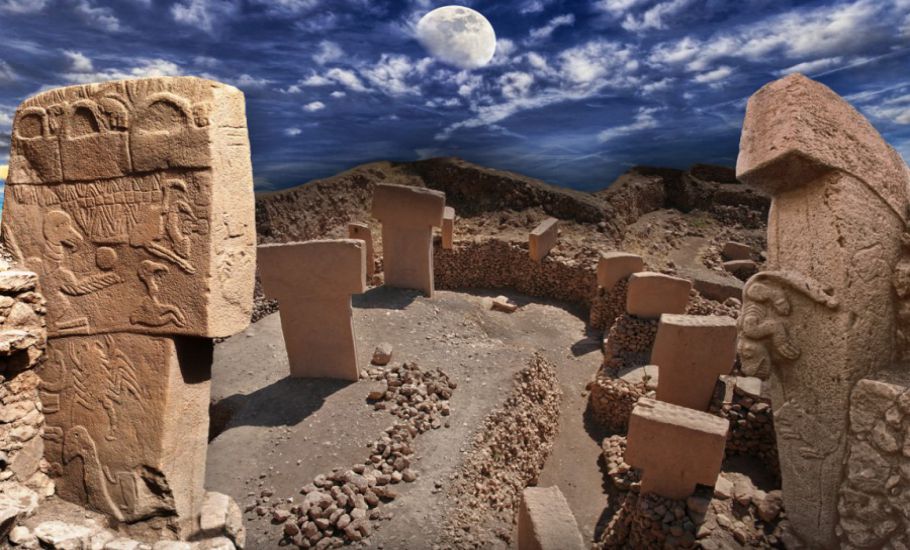

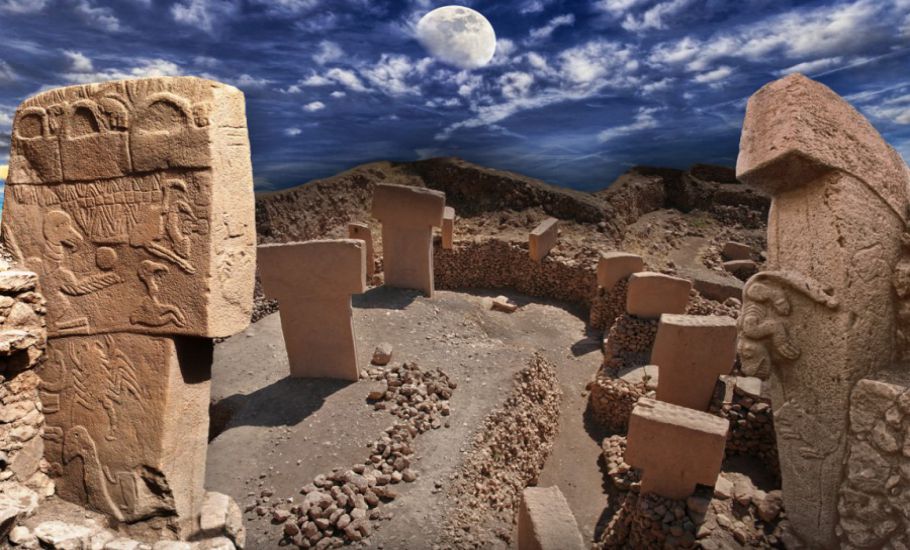

If they find some of the pillars that look like this

then that will be the shocker.

If they find some of the pillars that look like this

then that will be the shocker.

a reply to: Harte

Yes, it's cool. But the AE's had nothing but sand to cut granite with. Don't see how you put that on a lathe cutting tool. The scenes Stocks provides are of an artisanal stone worker's workshop, yet they only include the use of saws, pounders (pecking stones), rubbing stones and the upright grinders. Not the sort of place you would expect to see how they hauled heavy stone, though that IS depicted elsewhere, using ropes and sledges. Forked sticks used in the artwork is what Stocks duplicated. If they had lathes, why would they use that forked stick grinder at all? You obviously know that not ALL AE vessels had handles, and even if they did, that wouldn't prevent them from cutting out the interior of the vessel with a lathe. Nor would the handles prevent them from cutting the exterior with a lathe and leaving a blank at the top for a craftsman to cut the two handles out of. Makes no sense. Has to make some kind of sense or it's just daydreaming. Harte Besides, who would they brag to about that? Everyone in the area would have witnessed how a pyramid was built, but few went into these workshops.

You know and I know that all workshops DON’T all have the same equipment, capabilities and capacity.

Some have tooling and machines that others don’t .

Even Petrie suspected the use of ‘ jewelled tools’ way back then.

The fact that on many pieces , a rotational tooling Mark appears that shows complete revolutions of the tool biting in to the material means nothing to you as you don’t know what that means .

I’ve never denied how some vessels were made , as I’ve stated , as a machinist, we embrace different methods, want to try them.

Of course, the standard view of AE tooling is that it didn’t evolve in the thousands of years their dynasties existed . Do you think they used the same methods for all that time and didn’t improve anything? Didn’t expand any concepts? They had the same brains as us , and look what they accomplished? No tooling development over time and no variations between workshops’ equipment? I really can’t buy that.

The plate object we discussed is far too accurate for vertical production as you state, shows clear signs of turning.

The circular tooling mark we see on it just outside of centre is what could be called a “pause point” where the craftsman stopped briefly before continuing; maybe to grip the tool better for the last bit of the turning to the centre, or for a split second ‘achy arm’ moment before continuing. That’s when those type of marks appear on a lathe, when the smooth uninterrupted form of cutting it employs, is interrupted briefly .

Weird as it looks on , admittedly ,not the best picture, the centre kind of looks hexagonal (hex) ?!

It’s very reminiscent of ways we have today of holding a piece using the centre too, to add strength so that the workpiece is pinned to the chuck by its centre to ensure perfect concentricity throughout.

For those who don’t know , you can use a lathe like the bowl guy on the video or you can add to that set up a ‘centre’ , on the piece pushed against the workpiece for strength. Usually used for accuracy or hard materials. When a centre at the front of a piece is employed , you probably double the capability of what you achieve on a lathe.

Still waiting to hear your opinions on large circular saws, the RESULTANT edging produced by this .

The Petrie core analysis apparently confirming a single spiralled cut , and manufacturing repeatability of the Bent Pyramid casing stones .

Aren’t we lucky that I don’t reply to you with “Whatever” to your posts as a reply ,(very scientific I must say ) and wish to keep healthy debate open, even if the tooling side is a little difficult for you?

edit on 30-11-2019 by bluesfreak because: Spelling !

edit on 30-11-2019 by bluesfreak because: (no reason

given)

edit on 30-11-2019 by bluesfreak because: (no reason given)

edit on 30-11-2019 by bluesfreak because: (no

reason given)

originally posted by: Harte

originally posted by: Wolfenz

originally posted by: andy06shake

a reply to: LedermanStudio

Got to have been some kind of builder/technologically superior race that predates history.

But can we handle that?

Scientist cant even Handle PUMA PUNKU

It's the Fringe that can't handle Pumapunku.

Scientists have been handing it for over half a century.

The Non-Mystery of Pumapunku

Harte

So you place a Skeptoid Brian Dunning Website for a Reference !!

Now thats Funny!

The Man that Said ... if Regulate you food intake you wont produce Feces ! ( Take a Dump )

yeah he said that .. on Joe Rogan youtube Show ..

He constantly contradicts himself ...

Find a better Source Harte PLEASE... Someone Legit ...

in that Article ...

When you hear that an elephant is carved there, it certainly does give you pause, because an elephant is hard to mistake. However, when you look at a picture of what's claimed to be the elephant, this becomes less surprising. Tiwanaku art was highly stylized, much like what we're accustomed to seeing from the Maya or the Aztecs. It's actually the heads of two crested Andean Condors facing each other neck to neck, and their necks and crests constitute what some have compared to the tusks and ears of an elephant's face. The image of the toxodon is known only from rough sketches of a sculpture discovered in 1934, and so it's a drawing of indirect evidence of an artist's interpretation of an unknown subject. It looks to me like a generic quadruped. Pig, dog, rat, toxodon, name it.

Well..

Bones of elephant ancestor unearthed: Meet the gomphothere

www.sciencedaily.com...

Mexico finds 15,000-year-old 'mammoth traps'

edit on 22019TuesdayfAmerica/Chicago12336 by Wolfenz because: (no reason given)

Great find Wolfenz.

Unfortunately Harte doesn’t reply to difficult questions that he can’t make sweeping presumptuous proclamations about. Like my questions below to him:

“Still waiting to hear your opinions on large circular saws, the RESULTANT edging produced by this .

The Petrie core analysis apparently confirming a single spiralled cut , and manufacturing repeatability of the Bent Pyramid casing stones”

a reply to: Harte

Unfortunately Harte doesn’t reply to difficult questions that he can’t make sweeping presumptuous proclamations about. Like my questions below to him:

“Still waiting to hear your opinions on large circular saws, the RESULTANT edging produced by this .

The Petrie core analysis apparently confirming a single spiralled cut , and manufacturing repeatability of the Bent Pyramid casing stones”

a reply to: Harte

originally posted by: bluesfreak

Great find Wolfenz.

Unfortunately Harte doesn’t reply to difficult questions that he can’t make sweeping presumptuous proclamations about. Like my questions below to him:

“Still waiting to hear your opinions on large circular saws, the RESULTANT edging produced by this .

The Petrie core analysis apparently confirming a single spiralled cut , and manufacturing repeatability of the Bent Pyramid casing stones”

a reply to: Harte

You mean like you didn't reply to my question to you?

"What did they use as a cutting tool on your "lathe?"

I stopped responding when you pretended I didn't ask that question.

Hart

originally posted by: Wolfenz

originally posted by: Harte

originally posted by: Wolfenz

originally posted by: andy06shake

a reply to: LedermanStudio

Got to have been some kind of builder/technologically superior race that predates history.

But can we handle that?

Scientist cant even Handle PUMA PUNKU

It's the Fringe that can't handle Pumapunku.

Scientists have been handing it for over half a century.

The Non-Mystery of Pumapunku

Harte

So you place a Skeptoid Brian Dunning Website for a Reference !!

Now thats Funny!

The Man that Said ... if Regulate you food intake you wont produce Feces ! ( Take a Dump )

yeah he said that .. on Joe Rogan youtube Show ..

He constantly contradicts himself ...

Find a better Source Harte PLEASE... Someone Legit ...

in that Article ...

When you hear that an elephant is carved there, it certainly does give you pause, because an elephant is hard to mistake. However, when you look at a picture of what's claimed to be the elephant, this becomes less surprising. Tiwanaku art was highly stylized, much like what we're accustomed to seeing from the Maya or the Aztecs. It's actually the heads of two crested Andean Condors facing each other neck to neck, and their necks and crests constitute what some have compared to the tusks and ears of an elephant's face. The image of the toxodon is known only from rough sketches of a sculpture discovered in 1934, and so it's a drawing of indirect evidence of an artist's interpretation of an unknown subject. It looks to me like a generic quadruped. Pig, dog, rat, toxodon, name it.

Well..

Bones of elephant ancestor unearthed: Meet the gomphothere

www.sciencedaily.com...

Mexico finds 15,000-year-old 'mammoth traps'

Are you prepared to back up your claim that Tiwanaku is 15,000 years old now?

Or will you ignore that as well?

Harte

originally posted by: Harte

Are you prepared to back up your claim that Tiwanaku is 15,000 years old now?

Or will you ignore that as well?

Harte

Oh not the old 15,000 year claim - is this the one based on a extinct elephant (Cuvieronius) or the claim by Posnansky?

a reply to: Harte

"What did they use as a cutting tool on your "lathe?" I stopped responding when you pretended I didn't ask that question. Harte

There are many hard stones that could have been used. You see, to cut something , you need an object equally as hard or harder.

They could have used granite shards on a lathe. Granite shards would easily handle any stone softer than it; limestone alabaster , all of them. It would be harder than copper for sure.

They could have used diamond. Diamond is possibly the only way to achieve some of the tooling marks seen in granite, pay particular attention to the Petrie core, a continuous spiral cut it now seems.

Just as an aside, I’ve always wondered how the AE ‘formed’ their Copper tube drills .

One would have to bend a sheet of copper around a form to create its very circular shape . You might have to heat the sheet a bit first in order to obtain a nice even bend around an existing shape .

Let’s say they bend it around a wooden cylindrical form.

How does one achieve a substantially accurate cylinder in wood ?

You would have to turn it on a lathe.

How did they ‘join’ the two edges of the sheet once they had met, when bent around the said wooden former? They couldn’t solder/weld it together, because they didn’t have it.

They couldn’t have ‘brazed’ it together as that requires a constant jet of heat blasted at the joint . Or could they braze? I don’t know.

I am genuinely perplexed as to how this sheet of copper could hold itself together as a cylindrical form when pressure is applied as downforce upon it, combined with a twisting motion.

Some of the AE core holes are quite deep indeed.

If it’s a copper tube that cut the Petrie core, with one continuous spiral , that’s some downforce .

How did Stocks join this ‘seam’ ?

Even marking granite is hard ,I have a big piece of rose granite at home, have experimented a lot on it in my spare time seeing what is capable of just making a mark on it.

If you deduct from the test modern tooling (HSS Steel, Carbide, Ceramics, even, I suppose , iron from meteorites) what you are left with is diamond Or granite itself to do the cutting.

Petrie himself suggested “jewelled” tooling , why would that be?

I personally believe that we modern humans hold a confused view of diamonds that has been twisted into ‘value’ : yeah, they look pretty , but their real ‘Value’ is that they can cut anything on earth. (Including Aswan Rose granite)

So, that’s my view on AE lathe tooling that you enquire about .

Now, about the 35 foot saw blade, and the RESULTANT edging it leaves behind ?

About the Petrie core, which upon closer inspection seems to indeed reveal a continuous spiralled cut upon it?

The obvious repeatability of the Bent Pyramid casing stones?

Dear Harte, don’t forget to look at my reply to your lathe question above ! Oh, and my repeated questions in return, that you somehow avoid

answering.

Anyway, I’ve been doing a little digging regarding Stocks’ core drill experiment, regarding my questions relating to it in the post previous to this.

Here’s the video , an easy 5 min watch, a great piece of unintentional comedy :

youtu.be...

It appears Stocks solved the question of how the copper sheet is joined together along its seam , seeing as the AE could not weld, solder or Braze: —He bought himself a fully formed , probably extruded

( AE COULDNT DO THAT) copper pipe!! So funny! Didn’t even make one with the tooling and methods the AE had .

Next, it’s quite a thick looking modern made pipe- a cursory investigation of AE core drill holes reveals a tube drill of about 1mm thickness at the base of the cut. Stocks ignores this significant factor in the design of the tool.

They use STEEL wedges to remove the core!!! Why’s that , lads? Copper not strong enough to break it out???!!

If anyone fancies watching 5mins of self-congratulatory back slapping whilst ignoring major design issues and using materials the AE DIDNT HAVE, do check it out. Core stuff is about half way through.

Proof Stocks’ attempts are fundamentally flawed, and yet he’s made a career from this BS.

I just love the end where they triumphantly proclaim “ this could be a 4th dynasty core” well lads , no, not with tool you used or the method of extracting the core. The striations DO NOT look the same, even though they claim they are- no complete circular striations just a sand-mashed up mess.

Not science. An engineering joke.

Stocks never cut long straight lengths in granite, squared boxes,squared internally, curves, and didn’t use the correct methodology to perform this test.

Flawed and useless.

a reply to: Harte

Anyway, I’ve been doing a little digging regarding Stocks’ core drill experiment, regarding my questions relating to it in the post previous to this.

Here’s the video , an easy 5 min watch, a great piece of unintentional comedy :

youtu.be...

It appears Stocks solved the question of how the copper sheet is joined together along its seam , seeing as the AE could not weld, solder or Braze: —He bought himself a fully formed , probably extruded

( AE COULDNT DO THAT) copper pipe!! So funny! Didn’t even make one with the tooling and methods the AE had .

Next, it’s quite a thick looking modern made pipe- a cursory investigation of AE core drill holes reveals a tube drill of about 1mm thickness at the base of the cut. Stocks ignores this significant factor in the design of the tool.

They use STEEL wedges to remove the core!!! Why’s that , lads? Copper not strong enough to break it out???!!

If anyone fancies watching 5mins of self-congratulatory back slapping whilst ignoring major design issues and using materials the AE DIDNT HAVE, do check it out. Core stuff is about half way through.

Proof Stocks’ attempts are fundamentally flawed, and yet he’s made a career from this BS.

I just love the end where they triumphantly proclaim “ this could be a 4th dynasty core” well lads , no, not with tool you used or the method of extracting the core. The striations DO NOT look the same, even though they claim they are- no complete circular striations just a sand-mashed up mess.

Not science. An engineering joke.

Stocks never cut long straight lengths in granite, squared boxes,squared internally, curves, and didn’t use the correct methodology to perform this test.

Flawed and useless.

a reply to: Harte

new topics

-

Geddy Lee in Conversation with Alex Lifeson - My Effin’ Life

People: 20 minutes ago -

God lived as a Devil Dog.

Short Stories: 36 minutes ago -

Happy St George's day you bigots!

Breaking Alternative News: 2 hours ago -

TLDR post about ATS and why I love it and hope we all stay together somewhere

General Chit Chat: 3 hours ago -

Hate makes for strange bedfellows

US Political Madness: 5 hours ago -

Who guards the guards

US Political Madness: 7 hours ago -

Has Tesla manipulated data logs to cover up auto pilot crash?

Automotive Discussion: 9 hours ago

top topics

-

Hate makes for strange bedfellows

US Political Madness: 5 hours ago, 14 flags -

whistleblower Captain Bill Uhouse on the Kingman UFO recovery

Aliens and UFOs: 14 hours ago, 11 flags -

Who guards the guards

US Political Madness: 7 hours ago, 10 flags -

1980s Arcade

General Chit Chat: 16 hours ago, 7 flags -

Deadpool and Wolverine

Movies: 17 hours ago, 4 flags -

TLDR post about ATS and why I love it and hope we all stay together somewhere

General Chit Chat: 3 hours ago, 3 flags -

Has Tesla manipulated data logs to cover up auto pilot crash?

Automotive Discussion: 9 hours ago, 2 flags -

Happy St George's day you bigots!

Breaking Alternative News: 2 hours ago, 2 flags -

God lived as a Devil Dog.

Short Stories: 36 minutes ago, 1 flags -

Geddy Lee in Conversation with Alex Lifeson - My Effin’ Life

People: 20 minutes ago, 0 flags

active topics

-

God lived as a Devil Dog.

Short Stories • 1 • : FlyersFan -

Republican Voters Against Trump

2024 Elections • 285 • : Annee -

Happy St George's day you bigots!

Breaking Alternative News • 13 • : BedevereTheWise -

"We're All Hamas" Heard at Columbia University Protests

Social Issues and Civil Unrest • 243 • : FlyersFan -

Candidate TRUMP Now Has Crazy Judge JUAN MERCHAN After Him - The Stormy Daniels Hush-Money Case.

Political Conspiracies • 725 • : Justoneman -

SC Jack Smith is Using Subterfuge Tricks with Donald Trumps Upcoming Documents Trial.

Dissecting Disinformation • 108 • : Threadbarer -

So this is what Hamas considers 'freedom fighting' ...

War On Terrorism • 226 • : FlyersFan -

-@TH3WH17ERABB17- -Q- ---TIME TO SHOW THE WORLD--- -Part- --44--

Dissecting Disinformation • 616 • : cherokeetroy -

Geddy Lee in Conversation with Alex Lifeson - My Effin’ Life

People • 0 • : gortex -

British TV Presenter Refuses To Use Guest's Preferred Pronouns

Education and Media • 114 • : Annee