It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

share:

I've carried a knife from my child hood all the way through every single day at school until now.

I've never been without a knife but a day or two if one got lost.

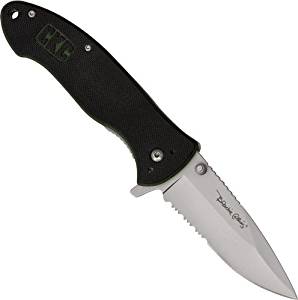

Today I still carry one except now I sleep with my knife every night. Its not a very special knife but it would shave hair when I bought it and I haven't managed to get it quite that sharp again but would like to.

What I do love about my knife is its quick lever. Its not a switch blade but very fast like a switch blade.

All knives like this with those flush mount screws that screw inside of the screw on the other side need taken apart and loc-tited.

They always manage to work loose.

Its a GKC Cowboy Up from tractor supply.

I've never been without a knife but a day or two if one got lost.

Today I still carry one except now I sleep with my knife every night. Its not a very special knife but it would shave hair when I bought it and I haven't managed to get it quite that sharp again but would like to.

What I do love about my knife is its quick lever. Its not a switch blade but very fast like a switch blade.

All knives like this with those flush mount screws that screw inside of the screw on the other side need taken apart and loc-tited.

They always manage to work loose.

Its a GKC Cowboy Up from tractor supply.

edit on 21-10-2019 by Trucker1 because: (no reason given)

a reply to: galadofwarthethird

Try shaving with a blade done on anything lower

Your razor will tug out more whiskers than it will cut.

Maybe it is the polish effect.

Try shaving with a blade done on anything lower

Your razor will tug out more whiskers than it will cut.

Maybe it is the polish effect.

edit on 14pMon, 21 Oct 2019 12:11:14 -050020192019-10-21T12:11:14-05:00kAmerica/Chicago31000000k by SprocketUK

because: Meh

a reply to: SprocketUK

I get pretty much all my knifes shaving sharp, on the 400 grit water stone, then the1000 grit oil stone then just use a strop. And they can all shave at that point. But ya, if I had better stones or higher grit, you can get some crazy sharp edges. But really, on most things dont need it.

A leather strop with some compound you find anywhere will do most of the finishing touches. In fact I dont need to sharpen all that much as long as I strop the knifes I use, ever so often after I use them. And they stay sharp, pretty much all the time.

But if I wanted to split hair or get it sharp enouph that if I even touch the hair it cuts it. Then ya, going to have to get some finer and harder stones, especially for any high carbide steels. But for 90% of everything else, you can get a knife shaving sharp just using a regular sharpening stone, and a leather strop with some compound they sell at any hardware store.

Any leather strop will do, in fact I use my leather belt if I need to once in a while, and that works as well as anything, really if you strop it after use, it will stay sharp pretty much indefinitely as long as you just use it for regular knife stuff, you know cutting rope, cardboard, wood and not whacking it into rocks, I done that as well.

As long as you dont wait till the edge at a micro level doesn't round over over long term use, or hammer it through hard stuff and dull or chip the edge. If you strop the edge after use, the carbines should realign and it will stay sharper much much longer. In the end thats what your cutting with, and what give you your cutting edge, the carbines in the steel is what gives steel its cutting properties.

Like this guy shows, all you need really to keep a keen edge on knifes.

I get pretty much all my knifes shaving sharp, on the 400 grit water stone, then the1000 grit oil stone then just use a strop. And they can all shave at that point. But ya, if I had better stones or higher grit, you can get some crazy sharp edges. But really, on most things dont need it.

A leather strop with some compound you find anywhere will do most of the finishing touches. In fact I dont need to sharpen all that much as long as I strop the knifes I use, ever so often after I use them. And they stay sharp, pretty much all the time.

But if I wanted to split hair or get it sharp enouph that if I even touch the hair it cuts it. Then ya, going to have to get some finer and harder stones, especially for any high carbide steels. But for 90% of everything else, you can get a knife shaving sharp just using a regular sharpening stone, and a leather strop with some compound they sell at any hardware store.

Any leather strop will do, in fact I use my leather belt if I need to once in a while, and that works as well as anything, really if you strop it after use, it will stay sharp pretty much indefinitely as long as you just use it for regular knife stuff, you know cutting rope, cardboard, wood and not whacking it into rocks, I done that as well.

As long as you dont wait till the edge at a micro level doesn't round over over long term use, or hammer it through hard stuff and dull or chip the edge. If you strop the edge after use, the carbines should realign and it will stay sharper much much longer. In the end thats what your cutting with, and what give you your cutting edge, the carbines in the steel is what gives steel its cutting properties.

Like this guy shows, all you need really to keep a keen edge on knifes.

a reply to: galadofwarthethird

I agree on the strop, I use one every time I sharpen and in between sharpenings. You can also keep an edge in pretty good condition with a steel if you know how to use one.

The only comment I have about the stropping technique he shows in the video is he needs to move a little faster. Maybe he just slowed down for demonstration purposes, but you want a little bit of heat to develop also when stropping. I don't use a belt how he demonstrates (though I have in the past). I generally use an actual strop attached to a block of wood clamped in a vice on my workbench. I also don't hold the knife at the same orientation the whole way through the stroke. I maintain the blade angle, but keep the edge perpendicular to the strop motion (i.e. rotate the knife towards the tip).

I agree on the strop, I use one every time I sharpen and in between sharpenings. You can also keep an edge in pretty good condition with a steel if you know how to use one.

The only comment I have about the stropping technique he shows in the video is he needs to move a little faster. Maybe he just slowed down for demonstration purposes, but you want a little bit of heat to develop also when stropping. I don't use a belt how he demonstrates (though I have in the past). I generally use an actual strop attached to a block of wood clamped in a vice on my workbench. I also don't hold the knife at the same orientation the whole way through the stroke. I maintain the blade angle, but keep the edge perpendicular to the strop motion (i.e. rotate the knife towards the tip).

[Looks around]

Where's semper?

It's a knife thread!!

Either you have the sharpening bug or you don't.

Shame such traditional skills are falling by the wayside.

Where's semper?

It's a knife thread!!

Either you have the sharpening bug or you don't.

Shame such traditional skills are falling by the wayside.

a reply to: galadofwarthethird

That's the thing, right there, it's far easier to maintain an edge than rescue it.

That's the thing, right there, it's far easier to maintain an edge than rescue it.

I have a fixation for sharp pointy things. I bought an antique saber a couple of months ago, took forever to find out anything about it, it's a Civil

War era artillery mans sword. It's in somewhat rough condition, but it's still got a rather impressive edge to it.

Almost a match for my big ol' Kukri.

My carry knife is a three inch Milwaukee tool folder. I got it for free when I bought a Milwaukee drill. It's a tough little knife that holds a edge far better than I ever thought it would... Along with my set of brass knucks--I feel almost bad ass .

My idea of heaven are big ol' knife and gun shows...so many sharp pointy things, and they're all for sale usually!!

Almost a match for my big ol' Kukri.

My carry knife is a three inch Milwaukee tool folder. I got it for free when I bought a Milwaukee drill. It's a tough little knife that holds a edge far better than I ever thought it would... Along with my set of brass knucks--I feel almost bad ass .

My idea of heaven are big ol' knife and gun shows...so many sharp pointy things, and they're all for sale usually!!

a reply to: seagull

Sometimes some of the best knives aren't some exotic custom made forged steel blade, but some knife you picked up somewhere under unusual circumstances, just like the one in my OP.

I had a really nice knife one time I took camping with me and busted a great big hunk out of the edge (ruining the knife) doing the simplest chore. It was a big knife too. I had a spare which was a carbon Mora I paid about $20 bucks for and figured I'd destroy it too. Nope, that knife did everything my really nice knife was supposed to do, and laughed all the way home. Towards the end of my trip I was purposely batoning things like oak, just to see if I could defeat the Mora. Nope, kept right on going...and it didn't even need that much sharpening when I got home.

Now I've got Mora's in every vehicle, and quite a few more in the garage, basement, out-buildings, tool boxes and other places. They're inexpensive, crazy sharp right out of the box and durable. So, why not. They might not always be my go-to knife just because I love so many of my knives, but I know they're always there.

Sometimes some of the best knives aren't some exotic custom made forged steel blade, but some knife you picked up somewhere under unusual circumstances, just like the one in my OP.

I had a really nice knife one time I took camping with me and busted a great big hunk out of the edge (ruining the knife) doing the simplest chore. It was a big knife too. I had a spare which was a carbon Mora I paid about $20 bucks for and figured I'd destroy it too. Nope, that knife did everything my really nice knife was supposed to do, and laughed all the way home. Towards the end of my trip I was purposely batoning things like oak, just to see if I could defeat the Mora. Nope, kept right on going...and it didn't even need that much sharpening when I got home.

Now I've got Mora's in every vehicle, and quite a few more in the garage, basement, out-buildings, tool boxes and other places. They're inexpensive, crazy sharp right out of the box and durable. So, why not. They might not always be my go-to knife just because I love so many of my knives, but I know they're always there.

a reply to: Flyingclaydisk

You can do it slow or fast. Dont think it matters that much. But If you wisk it on there fast, it could remove the burr or material on the edge faster and better likley.

But you can also overstrop. You do it to much, or you tilt the edge hard into the leather, you round off your edge like that.

Generally I use a wooden board strop with leather on it and added compound into the leather. If the leather is to soft, is not really optimal as its to soft and the edge will sort of dig into it, just keep it flat and dont push the edge into the leather strop basically.

Just a few swipes back and forth, really if your edge is not really dull, it will bring it back to shaving sharp right there or at the least sharp enouph to cut paper.

If its dull, then, ya your going to have to sharpen it on a stone or machine or whatever. Then strop it again. Really, I dont think anything beyond 1k or 2k is necessary to get any steel shaving sharp. Beyond that its just more or less polishing the apex of the edge.

Unless you have a high carbide steel, then you got to I would call it shave those carbides down at the apex of the edge. Then you need is a harder stone, or you can use the grinder, but generally grit of the stone does not matter if your trying to get a really sharp edge on alloyed steels like 3v or elmax, those steel or others like them form vandium carbides or other such carbides, as regular carbon steel just forms cementite which is just iron and carbon carbides, which are softer.

That or put it on the grinder.

Because you can have a 400 grit soft stone. And you can have a 400 grit hard stone like dimond or ceramic or those arkansa stones, or the more expensive water stones. There both at the same grit, but the harder stone will remove and cut into the steel better and faster. Its just as simple as that.

Which, really if your trying to split hair, or cut through wood or soft material, it works better the higher in grit you continue sharpening and refining the edge. But at that point your edge is microns thin. It wont last that long if you use your knife, much less on hard impact on hard surfaces. And if your using it to cut food like tomatoes or bread.

Really if you leave it ruff, or toothy. It would cut through most foods better, because its got more of a sawlike ununiform edge at the micro level, its basically a serrated edge at the micro level even though to the naked eye it looks even, put it under a powerfull microscope and its not all even at all, looks amost serated at that level.

And serated knifes cuts better and last longer through things like rope or bread, on wood and other stuff a mirror edge cuts better and lasts longer though, or at least for bushcrafting knifes anything that is more a mirror edge seems to last longer and cut deeper into the wood.

In fact if you look at knife edges through a microscope, even on the most thinnest and mirror polished edges, at a microlevel, its just not all one uniform edge, its more like a saw zig zag un-uniformed edge at those magnifications, and it just depends on how much you keep going and refine the edge with the higher grit and harder stones.

Really what your trying to do when you sharpen something, just depends on what your going to be using it for.

And for 99% of things, you don't need to be splitting hairs. Its just something some people do because its cool.

You can do it slow or fast. Dont think it matters that much. But If you wisk it on there fast, it could remove the burr or material on the edge faster and better likley.

But you can also overstrop. You do it to much, or you tilt the edge hard into the leather, you round off your edge like that.

Generally I use a wooden board strop with leather on it and added compound into the leather. If the leather is to soft, is not really optimal as its to soft and the edge will sort of dig into it, just keep it flat and dont push the edge into the leather strop basically.

Just a few swipes back and forth, really if your edge is not really dull, it will bring it back to shaving sharp right there or at the least sharp enouph to cut paper.

If its dull, then, ya your going to have to sharpen it on a stone or machine or whatever. Then strop it again. Really, I dont think anything beyond 1k or 2k is necessary to get any steel shaving sharp. Beyond that its just more or less polishing the apex of the edge.

Unless you have a high carbide steel, then you got to I would call it shave those carbides down at the apex of the edge. Then you need is a harder stone, or you can use the grinder, but generally grit of the stone does not matter if your trying to get a really sharp edge on alloyed steels like 3v or elmax, those steel or others like them form vandium carbides or other such carbides, as regular carbon steel just forms cementite which is just iron and carbon carbides, which are softer.

That or put it on the grinder.

Because you can have a 400 grit soft stone. And you can have a 400 grit hard stone like dimond or ceramic or those arkansa stones, or the more expensive water stones. There both at the same grit, but the harder stone will remove and cut into the steel better and faster. Its just as simple as that.

Which, really if your trying to split hair, or cut through wood or soft material, it works better the higher in grit you continue sharpening and refining the edge. But at that point your edge is microns thin. It wont last that long if you use your knife, much less on hard impact on hard surfaces. And if your using it to cut food like tomatoes or bread.

Really if you leave it ruff, or toothy. It would cut through most foods better, because its got more of a sawlike ununiform edge at the micro level, its basically a serrated edge at the micro level even though to the naked eye it looks even, put it under a powerfull microscope and its not all even at all, looks amost serated at that level.

And serated knifes cuts better and last longer through things like rope or bread, on wood and other stuff a mirror edge cuts better and lasts longer though, or at least for bushcrafting knifes anything that is more a mirror edge seems to last longer and cut deeper into the wood.

In fact if you look at knife edges through a microscope, even on the most thinnest and mirror polished edges, at a microlevel, its just not all one uniform edge, its more like a saw zig zag un-uniformed edge at those magnifications, and it just depends on how much you keep going and refine the edge with the higher grit and harder stones.

Really what your trying to do when you sharpen something, just depends on what your going to be using it for.

And for 99% of things, you don't need to be splitting hairs. Its just something some people do because its cool.

a reply to: SprocketUK

Way way easier to maintain an edge then to sharpen it all back up from being completely dull.

Really it just take a minute or two on a strop, every once in a while, or you can spend hours trying to sharpen back up a completely dull knife. A strop or even those ceramic rods just passing it through will do the trick.

Way way easier to maintain an edge then to sharpen it all back up from being completely dull.

Really it just take a minute or two on a strop, every once in a while, or you can spend hours trying to sharpen back up a completely dull knife. A strop or even those ceramic rods just passing it through will do the trick.

a reply to: Flyingclaydisk

Mora's are good knifes. There dirt cheep to. They use sandvik steels like 12c27, which is just a deviation and recopy of AEB-L steels so they dont have to pay royalties I think.

I always thought the steel was junk. But in terms of toughness for a stainless steel you cant beat it.

Its one of those things that you can find it everywere at dirt cheep prices, not because it sucks. But just because its used so much in everything, from razors to knifes to parts, to whatever else. That the companies make different variations of it, and sell it by the truckload.

The only bad thing about Mora knifes, is there not full tang, got a little rat tails tang. So if you try anything to crazy, they will snap at the handle.

Mora's are good knifes. There dirt cheep to. They use sandvik steels like 12c27, which is just a deviation and recopy of AEB-L steels so they dont have to pay royalties I think.

I always thought the steel was junk. But in terms of toughness for a stainless steel you cant beat it.

Its one of those things that you can find it everywere at dirt cheep prices, not because it sucks. But just because its used so much in everything, from razors to knifes to parts, to whatever else. That the companies make different variations of it, and sell it by the truckload.

The only bad thing about Mora knifes, is there not full tang, got a little rat tails tang. So if you try anything to crazy, they will snap at the handle.

My collection, decided to line them all up, or at least the ones that matter, got a few more hanging around, a kitchen knife, a little double edged

fighter knife somewhere, a few which I used and abused that are now mainly used to dig in the ground with, and a some wallmart machetes as well.

But besides the red handle bark river bravo knife, and the K-bar, all the rest I made. That tall one by the red handle knife is the latest, didn't even put an edge on it yet, gonna make a sheath for it, then sharpen it, then proceed to wack it into things. So take a picture while its still pretty.

But besides the red handle bark river bravo knife, and the K-bar, all the rest I made. That tall one by the red handle knife is the latest, didn't even put an edge on it yet, gonna make a sheath for it, then sharpen it, then proceed to wack it into things. So take a picture while its still pretty.

a reply to: galadofwarthethird

My eyes immediately went to the Bark River even before I finished reading your post. That's a sweet knife! Nice collection!

Is that a Damascus on the 2nd from the right (next to the Ka-Bar)?

I've got about 4 collections of anywhere from 7 - 20 knives each. I've got some customs I had made by a bladesmith (hand forged) by the name of Mark Smith, not sure if you ever heard of him. One where I had him leave some of the hammer marks up by the spine, some pretty exotic steel. I've also got a collection of Parangs from SE Asia and Machetes from South America, a collection of folders and a collection of fixed blade hunting / camp knives. And then there's the kitchen knives which are shared with my wife, but the Kyocera's, JA Henckles and Forschner's are mine and the Wusthof's are hers.

ETA - I'll bet I know right where you got that sheath on the top left. I almost bought one exactly like it. How do you like it?

My eyes immediately went to the Bark River even before I finished reading your post. That's a sweet knife! Nice collection!

Is that a Damascus on the 2nd from the right (next to the Ka-Bar)?

I've got about 4 collections of anywhere from 7 - 20 knives each. I've got some customs I had made by a bladesmith (hand forged) by the name of Mark Smith, not sure if you ever heard of him. One where I had him leave some of the hammer marks up by the spine, some pretty exotic steel. I've also got a collection of Parangs from SE Asia and Machetes from South America, a collection of folders and a collection of fixed blade hunting / camp knives. And then there's the kitchen knives which are shared with my wife, but the Kyocera's, JA Henckles and Forschner's are mine and the Wusthof's are hers.

ETA - I'll bet I know right where you got that sheath on the top left. I almost bought one exactly like it. How do you like it?

edit on

10/23/2019 by Flyingclaydisk because: (no reason given)

This place isn't too awfully far from us. I could probably get in some trouble going in there!!

Carbon Knife Co (Japanese)

This one would make a nice addition...

Saji R2 Ironwood Gyuto

Carbon Knife Co (Japanese)

This one would make a nice addition...

Saji R2 Ironwood Gyuto

a reply to: galadofwarthethird

You really know your steel! That's cool! I know quite a few, but I'm not at your level. I'm pretty much an oil-stone and strop guy. I haven't gotten into water stones (yet), so I'm thinking I probably couldn't hang with you on sharp, but I can definitely get them shaving sharp.

And, I agree, the whole edge strategy is really as much art as science. There's this delicate balance between edge angle and durability. It's fun to experiment around with.

And yes, seeing how sharp you can get some thing is more cool factor than necessary. It's fun though.

I bought a couple cheap Condor's just to play around with re-profiling. (partly because of the sheath's they sell with them are really nice, almost worth more than the knife). Condor's grind angle is terrible, but the steel is decent 1095 carbon, so you can work them. It took a while but I got this el-cheapo Condor bushcraft knife just "skeery sharp".

You really know your steel! That's cool! I know quite a few, but I'm not at your level. I'm pretty much an oil-stone and strop guy. I haven't gotten into water stones (yet), so I'm thinking I probably couldn't hang with you on sharp, but I can definitely get them shaving sharp.

And, I agree, the whole edge strategy is really as much art as science. There's this delicate balance between edge angle and durability. It's fun to experiment around with.

And yes, seeing how sharp you can get some thing is more cool factor than necessary. It's fun though.

I bought a couple cheap Condor's just to play around with re-profiling. (partly because of the sheath's they sell with them are really nice, almost worth more than the knife). Condor's grind angle is terrible, but the steel is decent 1095 carbon, so you can work them. It took a while but I got this el-cheapo Condor bushcraft knife just "skeery sharp".

a reply to: Flyingclaydisk

That bark river. Its a bravo 1.5 model. Its not bad. But I got it on sale a while ago, when it came the bevels were kind of offset. So I see why it was on sale, I fixed it, then I kind of rebroke it again. But it came with that cool leather sheath, which is not bad, prefer the wooden ones I make, there more sturdy, but the leather or kydex saves on ounces.

But not worried about ounces. In all its a really good sheath, dont think its standard bark river sheath, but it came with the knife.

I kind of messed it up already, cant tell in that pic but the tip is sort of just rounded off. Going to have to grind it down and change it to a drop point. I have been telling myself that for a year or more now, still have not got around to doing it, even though it would take me literally like 30 minutes on the grinder and some finishing work to turn it into a drop point.

The one your talking about next to the K-bar. Its monosteel, single steel, its a cru-v steel I was talking about earlier, never did a damascus, one day maybe I will, but I dont think there is any advantage over monosteel, will have to do a few and test them then break them, see if there is more to it then just cool wavy patterns.

But i seriously doupt it as its the microstructure of the steel, that give it its properties. Everything else may just be for looks.

The original reason why the japanese or spaniards and others did the folding technique is to remove impurities from the steel. And if you make you own steel in the back yard, your going to get impurities. And also, that knife was originally going to have a hamon on it. Never done it before, but should not be that hard, you can even use furnace cement instead of the original clay and ash mix, it will work, and i got a big bucket of it, just laying around.

But originally, when I made all those knifes, exept the fighter double edged one. Was more of a bushcraft or survival type knife. If I put a hamon on it, it will leave the spine soft, to soft to strike a ferro rod for any amount of time, and also to soft to use the spine of the knife for anything like scraping bark, or fat of hide, or even using the spine of the knife and a flint stone to start fires, as it will round off and become useless.

Its kind of like the whole premise I was originally wanted to do, only you know add a bit more curve. Also only did one knife by forging, well 2, that second from the left knife, the big one, I forged that, its the one I decided that I was eventualy going to do stainless steels more then carbon, around here, the moisture gets in everything.

In all just do stock removal, as all the steels that I want to make knifes out off, well there all air hardening steels, even AEB-L, you can probably forge it if you wanted to, or if you got a shop or something. But it would not be a good idea, as all stainless steels are air hardening steels, once you bring them to 1900F, and start hammering on them, your more likley to just create internal fractures then anything else.

Also eventually going to make me some knifes out of nitrogen steels, carbon and stainless chromium ultimately wont cut it. Some time down the line, when I break these or get bored of them, also kind of broke on the money department, so not going for anything to fancy or complicated right now.

But really just doing as a hobby, with my #ty propane forge, my 2x72 grinder, and one of those handheld drills you find anywere, and a handheld grinder with a cut off wheel, and a but load of time, here and there. Eventually though going to have to make my own steel as well, as even the most modern nitrogen steel out there, while expensive, and hard get your hands on, the ones I seen and looked at, that to wont cut it in the end.

That bark river. Its a bravo 1.5 model. Its not bad. But I got it on sale a while ago, when it came the bevels were kind of offset. So I see why it was on sale, I fixed it, then I kind of rebroke it again. But it came with that cool leather sheath, which is not bad, prefer the wooden ones I make, there more sturdy, but the leather or kydex saves on ounces.

But not worried about ounces. In all its a really good sheath, dont think its standard bark river sheath, but it came with the knife.

I kind of messed it up already, cant tell in that pic but the tip is sort of just rounded off. Going to have to grind it down and change it to a drop point. I have been telling myself that for a year or more now, still have not got around to doing it, even though it would take me literally like 30 minutes on the grinder and some finishing work to turn it into a drop point.

The one your talking about next to the K-bar. Its monosteel, single steel, its a cru-v steel I was talking about earlier, never did a damascus, one day maybe I will, but I dont think there is any advantage over monosteel, will have to do a few and test them then break them, see if there is more to it then just cool wavy patterns.

But i seriously doupt it as its the microstructure of the steel, that give it its properties. Everything else may just be for looks.

The original reason why the japanese or spaniards and others did the folding technique is to remove impurities from the steel. And if you make you own steel in the back yard, your going to get impurities. And also, that knife was originally going to have a hamon on it. Never done it before, but should not be that hard, you can even use furnace cement instead of the original clay and ash mix, it will work, and i got a big bucket of it, just laying around.

But originally, when I made all those knifes, exept the fighter double edged one. Was more of a bushcraft or survival type knife. If I put a hamon on it, it will leave the spine soft, to soft to strike a ferro rod for any amount of time, and also to soft to use the spine of the knife for anything like scraping bark, or fat of hide, or even using the spine of the knife and a flint stone to start fires, as it will round off and become useless.

Its kind of like the whole premise I was originally wanted to do, only you know add a bit more curve. Also only did one knife by forging, well 2, that second from the left knife, the big one, I forged that, its the one I decided that I was eventualy going to do stainless steels more then carbon, around here, the moisture gets in everything.

In all just do stock removal, as all the steels that I want to make knifes out off, well there all air hardening steels, even AEB-L, you can probably forge it if you wanted to, or if you got a shop or something. But it would not be a good idea, as all stainless steels are air hardening steels, once you bring them to 1900F, and start hammering on them, your more likley to just create internal fractures then anything else.

Also eventually going to make me some knifes out of nitrogen steels, carbon and stainless chromium ultimately wont cut it. Some time down the line, when I break these or get bored of them, also kind of broke on the money department, so not going for anything to fancy or complicated right now.

But really just doing as a hobby, with my #ty propane forge, my 2x72 grinder, and one of those handheld drills you find anywere, and a handheld grinder with a cut off wheel, and a but load of time, here and there. Eventually though going to have to make my own steel as well, as even the most modern nitrogen steel out there, while expensive, and hard get your hands on, the ones I seen and looked at, that to wont cut it in the end.

a reply to: Flyingclaydisk

We live such different lives. Out here in the Vegas the only reason to carry a knife is to stab someone in the gullet. I would never have thought of using a knife to cut barbed wire, heck, I didn't know a knife could cut barbed wire.

I do use an x-acto to clean my fingernails. Does that count?

My "chefs" knife is a cheap-o serrated blade. Cost me about 8 bucks. Had it for almost 20 years and it's never been sharpened(don't think you can with serrated) and still cuts like a charm. Food, that is. I ain't serving up fine foods, basically serving myself and I don't want, nor can afford, a bunch of really good knives all for different purposes. I have a one size fits all. works for me.

We live such different lives. Out here in the Vegas the only reason to carry a knife is to stab someone in the gullet. I would never have thought of using a knife to cut barbed wire, heck, I didn't know a knife could cut barbed wire.

I do use an x-acto to clean my fingernails. Does that count?

My "chefs" knife is a cheap-o serrated blade. Cost me about 8 bucks. Had it for almost 20 years and it's never been sharpened(don't think you can with serrated) and still cuts like a charm. Food, that is. I ain't serving up fine foods, basically serving myself and I don't want, nor can afford, a bunch of really good knives all for different purposes. I have a one size fits all. works for me.

a reply to: Flyingclaydisk

I have been monkeying around a bit. I stopped even doing bevels, as I eventually end up hand filling and hand sanding things, its more of the same. I just grind a full grind now from the edge to the top of the spine. Mainly because the knife I last did it on, I did a whole test on it, and the whole full grind or saber grind all the way to the top, sinks into wood and bites deeper if you hack into wood.

So, started to do the whole full saber/convex grind thing. Makes the knifes look more plain, like kitchen knifes, but there way more effective at cutting and chopping and bitting deep into wood and other stuff. From all the stuff I did already. I would say, 90% is knife geometry for any given task, and the rest is just what kind of steel your using.

That knife in that pic I posted, the first one from the left. I wacked that into a rock completley chipping the edge and smushing it in, and that was after I choped a brick and some aluminum rods. It was thick to begin with. Then I resharpened it, but now the edge is so thick that its even thicker then an axe. Its useless as a knife now.

Going to have to regrind it down, and fix it. But steel is steal. Even tried that whole myth you see in movies were they sword fight and its edge on edge contact. Oh boy! Even on almost untempered steel at close to its max hardness, the knifes I used turned into a sawblades with all the chipping at the edge.

So ya, the majority of believes people have about steel, not matter how fancy. Are myth, even modern steels, the so called super steels, are anything but super. They have one big advantage over carbon and more cheaper stainless steels. There wear resistance.

But all of the modern steels, while there edge lasts longer cutting things. They are brittle as all hell compared to simple steels, if there at the same HRC level. If you make something thin like a kitchen knife, and anything above 61 hrc, it will literally break in half easily if wack it into something hard like a nail, or even really dense dried wood.

But!

You make it a bit thicker, and it will survive. Point being, its geometry overall, but most modern steels there just brittle compared to regular ol carbon steel, or simple less carbide stainless steels. In the end its a trade off on two things.

How long you want your cutting edge to last? For how though and not brittle you want your knife to be? When it comes to most steels, really thats all there is to it.

Really the best and most knowledgeable site I found around on knive steels, or really knifes in general is knifesteelnerds.

Its got everything in there you really need to know about knifes steels.

Even that link, were he links the different types of steels and there micrograps, all you need to do is take one look at those pictures and compare it to the other steels, and it all makes sense why some steels are they way they are.

Just look at that picture of the micrograph of D2 steel. I made a knife out of it, made it thin at first razor edge thin, and the edge literally took big chunks out of it, while whittling hard wood and a brass rod.

I changed the angle of my sharpening on the stones, and then whittled a bit more into the brass rod. And it was fine, no giant chips or crumpled edges, simply just by changing the angle of the edge and making it a convex edge, instead of a straight down thin razor edge.

It literally changed everything, with a slight flip in my sharpening angle. Though D2 is not really a good steel for making thin edged knifes. If you look at that micrograph in the site I linked. You will see why.

I have been monkeying around a bit. I stopped even doing bevels, as I eventually end up hand filling and hand sanding things, its more of the same. I just grind a full grind now from the edge to the top of the spine. Mainly because the knife I last did it on, I did a whole test on it, and the whole full grind or saber grind all the way to the top, sinks into wood and bites deeper if you hack into wood.

So, started to do the whole full saber/convex grind thing. Makes the knifes look more plain, like kitchen knifes, but there way more effective at cutting and chopping and bitting deep into wood and other stuff. From all the stuff I did already. I would say, 90% is knife geometry for any given task, and the rest is just what kind of steel your using.

That knife in that pic I posted, the first one from the left. I wacked that into a rock completley chipping the edge and smushing it in, and that was after I choped a brick and some aluminum rods. It was thick to begin with. Then I resharpened it, but now the edge is so thick that its even thicker then an axe. Its useless as a knife now.

Going to have to regrind it down, and fix it. But steel is steal. Even tried that whole myth you see in movies were they sword fight and its edge on edge contact. Oh boy! Even on almost untempered steel at close to its max hardness, the knifes I used turned into a sawblades with all the chipping at the edge.

So ya, the majority of believes people have about steel, not matter how fancy. Are myth, even modern steels, the so called super steels, are anything but super. They have one big advantage over carbon and more cheaper stainless steels. There wear resistance.

But all of the modern steels, while there edge lasts longer cutting things. They are brittle as all hell compared to simple steels, if there at the same HRC level. If you make something thin like a kitchen knife, and anything above 61 hrc, it will literally break in half easily if wack it into something hard like a nail, or even really dense dried wood.

But!

You make it a bit thicker, and it will survive. Point being, its geometry overall, but most modern steels there just brittle compared to regular ol carbon steel, or simple less carbide stainless steels. In the end its a trade off on two things.

How long you want your cutting edge to last? For how though and not brittle you want your knife to be? When it comes to most steels, really thats all there is to it.

Really the best and most knowledgeable site I found around on knive steels, or really knifes in general is knifesteelnerds.

Its got everything in there you really need to know about knifes steels.

Even that link, were he links the different types of steels and there micrograps, all you need to do is take one look at those pictures and compare it to the other steels, and it all makes sense why some steels are they way they are.

Just look at that picture of the micrograph of D2 steel. I made a knife out of it, made it thin at first razor edge thin, and the edge literally took big chunks out of it, while whittling hard wood and a brass rod.

I changed the angle of my sharpening on the stones, and then whittled a bit more into the brass rod. And it was fine, no giant chips or crumpled edges, simply just by changing the angle of the edge and making it a convex edge, instead of a straight down thin razor edge.

It literally changed everything, with a slight flip in my sharpening angle. Though D2 is not really a good steel for making thin edged knifes. If you look at that micrograph in the site I linked. You will see why.

originally posted by: Lumenari

a reply to: Flyingclaydisk

I prefer obsidian blades.

er not the best for most stuff.........but great for fighting and skinning!

a reply to: TheSpanishArcher

Just kind of a hobby. I just like them.

Wouldn't ever plan on bring one to something like say, a gunfight.

Just kind of a hobby. I just like them.

Wouldn't ever plan on bring one to something like say, a gunfight.

new topics

-

HORRIBLE !! Russian Soldier Drinking Own Urine To Survive In Battle

World War Three: 1 hours ago -

Bobiverse

Fantasy & Science Fiction: 4 hours ago -

Florida man's trip overseas ends in shock over $143,000 T-Mobile phone bill

Social Issues and Civil Unrest: 4 hours ago -

Former Labour minister Frank Field dies aged 81

People: 6 hours ago -

SETI chief says US has no evidence for alien technology. 'And we never have'

Aliens and UFOs: 8 hours ago -

This is our Story

General Entertainment: 10 hours ago

top topics

-

President BIDEN Vows to Make Americans Pay More Federal Taxes in 2025 - Political Suicide.

2024 Elections: 13 hours ago, 16 flags -

One Flame Throwing Robot Dog for Christmas Please!

Weaponry: 17 hours ago, 6 flags -

Florida man's trip overseas ends in shock over $143,000 T-Mobile phone bill

Social Issues and Civil Unrest: 4 hours ago, 6 flags -

SETI chief says US has no evidence for alien technology. 'And we never have'

Aliens and UFOs: 8 hours ago, 6 flags -

Don't take advantage of people just because it seems easy it will backfire

Rant: 17 hours ago, 4 flags -

Ditching physical money

History: 17 hours ago, 4 flags -

Former Labour minister Frank Field dies aged 81

People: 6 hours ago, 4 flags -

Bobiverse

Fantasy & Science Fiction: 4 hours ago, 3 flags -

This is our Story

General Entertainment: 10 hours ago, 3 flags -

Ode to Artemis

General Chit Chat: 13 hours ago, 3 flags

active topics

-

American Government to Sanction Israel Defence Force in the West Bank

Middle East Issues • 54 • : yuppa -

-@TH3WH17ERABB17- -Q- ---TIME TO SHOW THE WORLD--- -Part- --44--

Dissecting Disinformation • 645 • : Thoughtful3 -

Florida man's trip overseas ends in shock over $143,000 T-Mobile phone bill

Social Issues and Civil Unrest • 5 • : Consvoli -

Breaking Baltimore, ship brings down bridge, mass casualties

Other Current Events • 478 • : IndieA -

Russia Ukraine Update Thread - part 3

World War Three • 5726 • : stu119 -

Thousands Of Young Ukrainian Men Trying To Flee The Country To Avoid Conscription And The War

Other Current Events • 129 • : yuppa -

One Flame Throwing Robot Dog for Christmas Please!

Weaponry • 10 • : ATruGod -

HORRIBLE !! Russian Soldier Drinking Own Urine To Survive In Battle

World War Three • 8 • : Astyanax -

New whistleblower Jason Sands speaks on Twitter Spaces last night.

Aliens and UFOs • 51 • : Ophiuchus1 -

The Reality of the Laser

Military Projects • 40 • : Zaphod58