It looks like you're using an Ad Blocker.

Please white-list or disable AboveTopSecret.com in your ad-blocking tool.

Thank you.

Some features of ATS will be disabled while you continue to use an ad-blocker.

2

share:

source

So I was talking to a female(I know first time in ten years) today and she's about to finish college. Well I was telling her about 3d printing and she said, "they are so cool my school is buying more of those!". Well that was confirmation for me that the future of manufacturing is about to hit the United states and reinvigorate our economy.

Yeah I think CNC programming and CAD is a great idea.

Thanks to a combination of university gift funds and grants, the library soon acquired its two 3D printers. The 3DTouch arrived first on April 27th and was printing its first job — a rotor for an impeller pump prototype designed by a group of engineering students — just minutes later. The rotor would take three days to finish.

So I was talking to a female(I know first time in ten years) today and she's about to finish college. Well I was telling her about 3d printing and she said, "they are so cool my school is buying more of those!". Well that was confirmation for me that the future of manufacturing is about to hit the United states and reinvigorate our economy.

Yeah I think CNC programming and CAD is a great idea.

edit on 10/21/2014 by onequestion because: (no reason given)

a reply to: onequestion

I don't think anything will change other then these new tools will give production access to a larger set of people.

With worldwide access to these machines everyone is still in the production game.

I don't think anything will change other then these new tools will give production access to a larger set of people.

With worldwide access to these machines everyone is still in the production game.

originally posted by: onequestion

source

Thanks to a combination of university gift funds and grants, the library soon acquired its two 3D printers. The 3DTouch arrived first on April 27th and was printing its first job — a rotor for an impeller pump prototype designed by a group of engineering students — just minutes later. The rotor would take three days to finish.

So I was talking to a female(I know first time in ten years) today and she's about to finish college. Well I was telling her about 3d printing and she said, "they are so cool my school is buying more of those!". Well that was confirmation for me that the future of manufacturing is about to hit the United states and reinvigorate our economy.

Yeah I think CNC programming and CAD is a great idea.

Care to explain how you think this will "reinvigorate our economy"? Seems to me this will reduce the amount of "workers" required to produce goods.

a reply to: TycoonBarnaby

Small manufacturing and an inventors paradise. The smaller manufacturers will be able to compete with product prices. Freight cost and so on.

Small manufacturing and an inventors paradise. The smaller manufacturers will be able to compete with product prices. Freight cost and so on.

originally posted by: onequestion

a reply to: TycoonBarnaby

Small manufacturing and an inventors paradise. The smaller manufacturers will be able to compete with product prices. Freight cost and so on.

How will piracy be policed? If it becomes easy enough for a small business to do 3D printing, how do you propose we 'police' the general public from downloading schematics and printing up what they would otherwise have to pay for?

a reply to: TycoonBarnaby

Hmm. Yeah.

Where are the materials going to come from? Bet they'll need a lisence to buy the materials and create some kind of legalities around it.

Hmm. Yeah.

Where are the materials going to come from? Bet they'll need a lisence to buy the materials and create some kind of legalities around it.

originally posted by: onequestion

a reply to: TycoonBarnaby

Hmm. Yeah.

Where are the materials going to come from? Bet they'll need a lisence to buy the materials and create some kind of legalities around it.

Legalities.. thus my reference to piracy.

Materials, as far as requiring a license to acquire, covers a small subset of what could be created/printed.

a reply to: TycoonBarnaby

I've got one thing to say "Lego's"!

I guarantee they will be at the forefront of what you are speaking.

I've got one thing to say "Lego's"!

I guarantee they will be at the forefront of what you are speaking.

Material access for 3d printers is fairly open right now. I can't imagine that changing because limiting the materials severely limits the

usefulness of the technology.

When it comes to patterns take it from someone who can make them... it's not a big deal. We already have many websites out there where 3d models can be purchased or obtained for free. Those models can then be sent to a printer. It's really no different from you being able to copy/paste a news article, print it out, and then take it somewhere and show it to a person. The only difference here is that you're printing an object rather than information.

The real questions to be asking is how this is going to impact restricted items. Guns, knives, certain bullet casings, and so on. 3d printing lets you create all of these things. Any sort of regulation on obtaining them is going to vanish.

When it comes to patterns take it from someone who can make them... it's not a big deal. We already have many websites out there where 3d models can be purchased or obtained for free. Those models can then be sent to a printer. It's really no different from you being able to copy/paste a news article, print it out, and then take it somewhere and show it to a person. The only difference here is that you're printing an object rather than information.

The real questions to be asking is how this is going to impact restricted items. Guns, knives, certain bullet casings, and so on. 3d printing lets you create all of these things. Any sort of regulation on obtaining them is going to vanish.

I have one in the corner of my office printing away as I type.

There are a huge amount of open source cad drawings available that you can simply download and print the part. Printed a fan shroud for a older Dell server the other day as the replacement could not be sourced without a huge delay as it is a somewhat rural area. 2 hours of downtime was much more preferable to several days.

Just to freak out my dentist I used the latest CT scan of my lower jaw and printed a scale replica of it.

When the printer is dialed in it has sub millimeter accuracy.

Huge time saver for me in many respects.

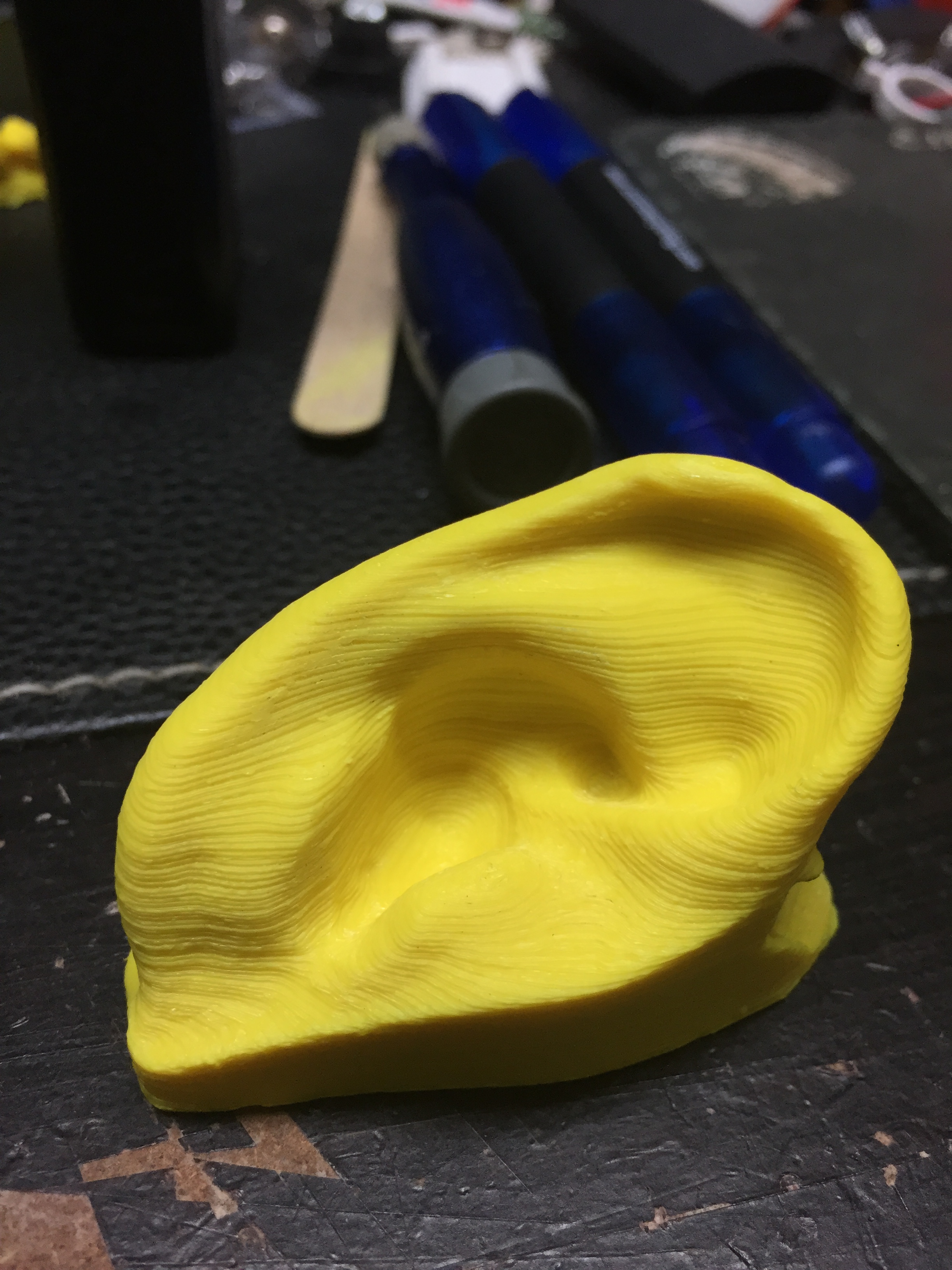

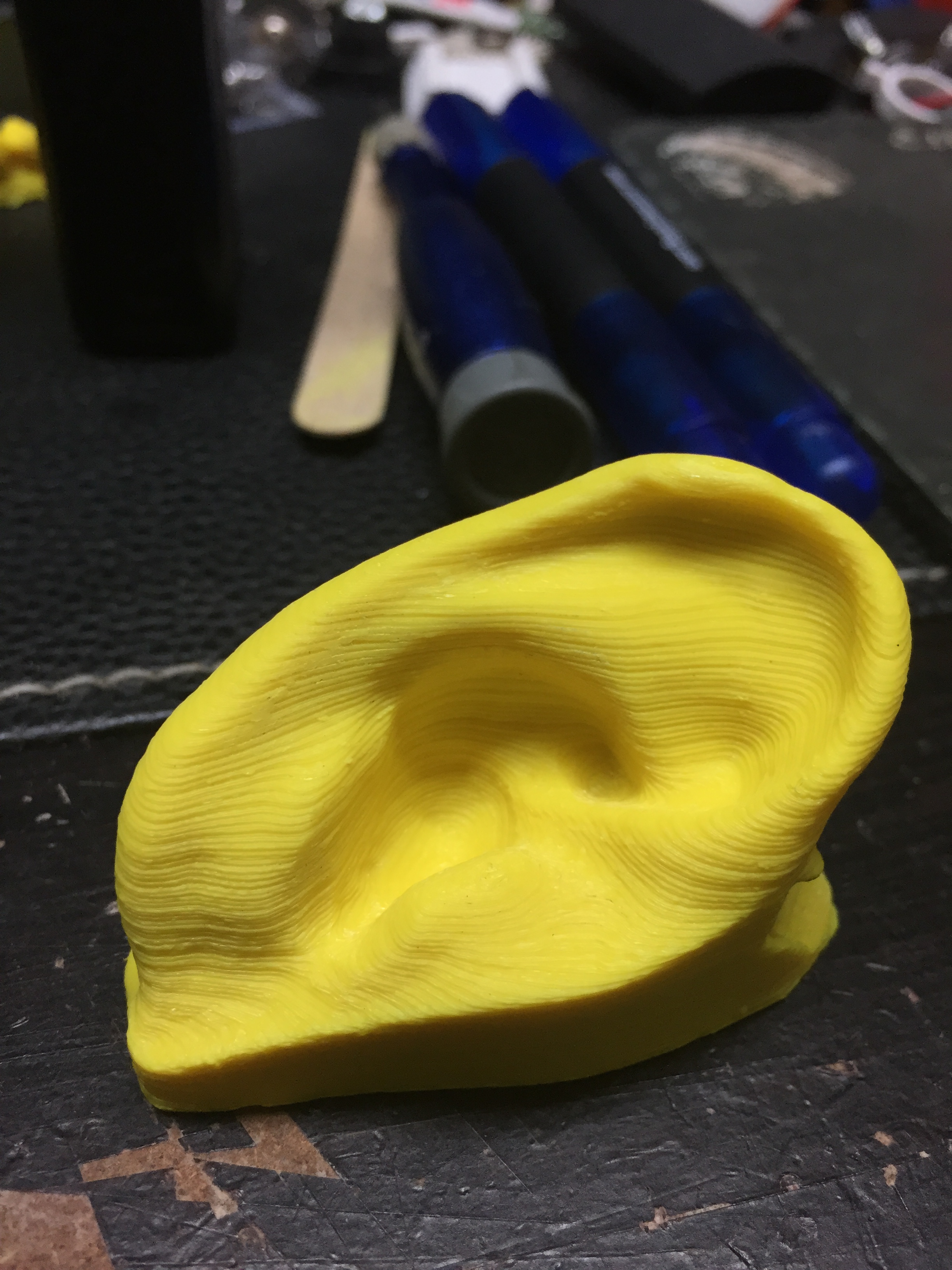

Here is an example of what it can do right off the print bed with no touch up.

There are a huge amount of open source cad drawings available that you can simply download and print the part. Printed a fan shroud for a older Dell server the other day as the replacement could not be sourced without a huge delay as it is a somewhat rural area. 2 hours of downtime was much more preferable to several days.

Just to freak out my dentist I used the latest CT scan of my lower jaw and printed a scale replica of it.

When the printer is dialed in it has sub millimeter accuracy.

Huge time saver for me in many respects.

Here is an example of what it can do right off the print bed with no touch up.

a reply to: AkHolic

What programs are you using to convert from autocad if any?

Is it 3DS, DXF or just the plain DWG that gets converted?

I'm really starting to wonder when my office could benefit from one of these, right now it's a novelty for architecture(in most cases, I've seen some incredible examples already though). If the learning curve is high it might be smart to get one early on to experiment with until they become more standardized. . .

What type of printing material is used, can it be interchanged?

Sorry for all the questions, I have only looked at this tech from a discreet distance so far. NJIT had one in 1996 but it was a prototype.

What programs are you using to convert from autocad if any?

Is it 3DS, DXF or just the plain DWG that gets converted?

I'm really starting to wonder when my office could benefit from one of these, right now it's a novelty for architecture(in most cases, I've seen some incredible examples already though). If the learning curve is high it might be smart to get one early on to experiment with until they become more standardized. . .

What type of printing material is used, can it be interchanged?

Sorry for all the questions, I have only looked at this tech from a discreet distance so far. NJIT had one in 1996 but it was a prototype.

a reply to: AnteBellum

I'm using Solid Works. Exports to most of the popular printer file types such as .slt .

The problem with many medical scans is that the CT has more slices than the program can render in a timely manner. It is not that it can't, it just takes some time even on a fairly strong computer.

As for material, ABS is the most common and cheapest.

If the printers extruder (heating nozzle like the end of a hot glue gun) can be adjusted for temperature, other plastics can be used like PLA as well as semi-flex plastics. If you have 2 extruders you can print in multiple colors.

Much like the data used for the printing the material has to be somewhat pure. No going to the homer depot and loading up on weed eater line. Crap in = crap out....

In my case Solid Works and a $500 da Vinci 1.0 and le the fun begin!

I'm using Solid Works. Exports to most of the popular printer file types such as .slt .

The problem with many medical scans is that the CT has more slices than the program can render in a timely manner. It is not that it can't, it just takes some time even on a fairly strong computer.

As for material, ABS is the most common and cheapest.

If the printers extruder (heating nozzle like the end of a hot glue gun) can be adjusted for temperature, other plastics can be used like PLA as well as semi-flex plastics. If you have 2 extruders you can print in multiple colors.

Much like the data used for the printing the material has to be somewhat pure. No going to the homer depot and loading up on weed eater line. Crap in = crap out....

In my case Solid Works and a $500 da Vinci 1.0 and le the fun begin!

originally posted by: TycoonBarnaby

originally posted by: onequestion

a reply to: TycoonBarnaby

Small manufacturing and an inventors paradise. The smaller manufacturers will be able to compete with product prices. Freight cost and so on.

How will piracy be policed? If it becomes easy enough for a small business to do 3D printing, how do you propose we 'police' the general public from downloading schematics and printing up what they would otherwise have to pay for?

There are existing laws and anti-counterfeit departments to deal with the problem of copyright and trademark infringement. To defeat copycats, your tactic is to go for niche markets that have low demand/high price and to do continuous development so that a new product comes out faster that a copycat can reverse engineer your product. Then it is simply just not profitable for a copycat to go to the effort.

Another strategy is to make your product way more complex than a copycat can reproduce. If you concentrate on electronic gadgets say mini drones with CCD cameras, 3D printing is only a quarter of the product. It gives you the propeller blades, fins and chassis. Custom circuit boards and firmware let you do the camera work, and a few PC and mobile applications let you operate it remotely. Then you also need packaging for a colorful box, shrink wrap, instruction manuals, assembly guides and an inventory. That is way too much cost for a basement living copycat.

a reply to: onequestion

I was surprised as well when I found out a friend was using these at their school. Instead of bringing manufacturing jobs to the U.S., I feel that 3D printing will essentially decentralize any manufacturing giants. As time progresses, the materials used in 3D printing will only get better, the same for the machines themselves. Prices will also drop, as will the "know-how" requirements.

Think about this: In ten years, no one will buy phones because they look cool. They'll be buying them based solely for the hardware specifications as we'll be making 100% custom cases for them ourselves. I surmise the same can be said on a varying scale for cars, motorcycles, clothing (watches, shoes), and more.

I was surprised as well when I found out a friend was using these at their school. Instead of bringing manufacturing jobs to the U.S., I feel that 3D printing will essentially decentralize any manufacturing giants. As time progresses, the materials used in 3D printing will only get better, the same for the machines themselves. Prices will also drop, as will the "know-how" requirements.

Think about this: In ten years, no one will buy phones because they look cool. They'll be buying them based solely for the hardware specifications as we'll be making 100% custom cases for them ourselves. I surmise the same can be said on a varying scale for cars, motorcycles, clothing (watches, shoes), and more.

a reply to: Auricom

This is only part of it. A 3d printer can make the pieces but assembly is still required. Essentially what you're going to see in the future is engineers/designers creating an item, then breaking it into pieces for printing, and then hiring people (or the end user) to assemble it.

This is only part of it. A 3d printer can make the pieces but assembly is still required. Essentially what you're going to see in the future is engineers/designers creating an item, then breaking it into pieces for printing, and then hiring people (or the end user) to assemble it.

new topics

-

Is the origin for the Eye of Horus the pineal gland?

General Conspiracies: 1 hours ago -

Man sets himself on fire outside Donald Trump trial

Mainstream News: 1 hours ago -

Biden says little kids flip him the bird all the time.

2024 Elections: 1 hours ago -

The Democrats Take Control the House - Look what happened while you were sleeping

US Political Madness: 2 hours ago -

Sheetz facing racial discrimination lawsuit for considering criminal history in hiring

Social Issues and Civil Unrest: 2 hours ago -

In an Historic First, In N Out Burger Permanently Closes a Location

Mainstream News: 4 hours ago -

MH370 Again....

Disaster Conspiracies: 5 hours ago -

Are you ready for the return of Jesus Christ? Have you been cleansed by His blood?

Religion, Faith, And Theology: 7 hours ago -

Chronological time line of open source information

History: 8 hours ago -

A man of the people

Medical Issues & Conspiracies: 9 hours ago

top topics

-

In an Historic First, In N Out Burger Permanently Closes a Location

Mainstream News: 4 hours ago, 14 flags -

The Democrats Take Control the House - Look what happened while you were sleeping

US Political Madness: 2 hours ago, 9 flags -

A man of the people

Medical Issues & Conspiracies: 9 hours ago, 8 flags -

Thousands Of Young Ukrainian Men Trying To Flee The Country To Avoid Conscription And The War

Other Current Events: 15 hours ago, 7 flags -

Biden says little kids flip him the bird all the time.

2024 Elections: 1 hours ago, 6 flags -

Man sets himself on fire outside Donald Trump trial

Mainstream News: 1 hours ago, 5 flags -

12 jurors selected in Trump criminal trial

US Political Madness: 17 hours ago, 4 flags -

4 plans of US elites to defeat Russia

New World Order: 11 hours ago, 4 flags -

Are you ready for the return of Jesus Christ? Have you been cleansed by His blood?

Religion, Faith, And Theology: 7 hours ago, 3 flags -

Sheetz facing racial discrimination lawsuit for considering criminal history in hiring

Social Issues and Civil Unrest: 2 hours ago, 3 flags

active topics

-

12 jurors selected in Trump criminal trial

US Political Madness • 85 • : matafuchs -

Marjorie Taylor Greene Files Motion to Vacate Speaker Mike Johnson

US Political Madness • 64 • : interupt42 -

The Democrats Take Control the House - Look what happened while you were sleeping

US Political Madness • 20 • : CriticalStinker -

Man sets himself on fire outside Donald Trump trial

Mainstream News • 17 • : FlyersFan -

Biden says little kids flip him the bird all the time.

2024 Elections • 8 • : Astrocometus -

Are you ready for the return of Jesus Christ? Have you been cleansed by His blood?

Religion, Faith, And Theology • 18 • : mysterioustranger -

Israeli Missile Strikes in Iran, Explosions in Syria + Iraq

World War Three • 101 • : CarlLaFong -

Thousands Of Young Ukrainian Men Trying To Flee The Country To Avoid Conscription And The War

Other Current Events • 26 • : Lazy88 -

George Knapp AMA on DI

Area 51 and other Facilities • 27 • : TheValeyard -

4 plans of US elites to defeat Russia

New World Order • 35 • : Oldcarpy2

2